A woodworking square is a crucial tool for achieving precise, accurate angles in woodworking projects. Also known as a carpenter’s square or framing square, this tool is designed to measure and mark 90-degree angles, ensuring that joints, cuts, and corners are perfectly squared.

Woodworking squares come in various types, including try squares, speed squares, and framing squares, each tailored to different tasks. For example, a speed square is compact and perfect for quick angle measurements on smaller projects, while a larger framing square is ideal for framing and layout work.

By providing accurate angles and straight lines, a woodworking square helps you create sturdy, professional-quality pieces, whether you’re building furniture, installing cabinets, or framing structures. It’s a must-have for any woodworker striving for precision and quality in their craft.

Our Top Woodworking Square Picks

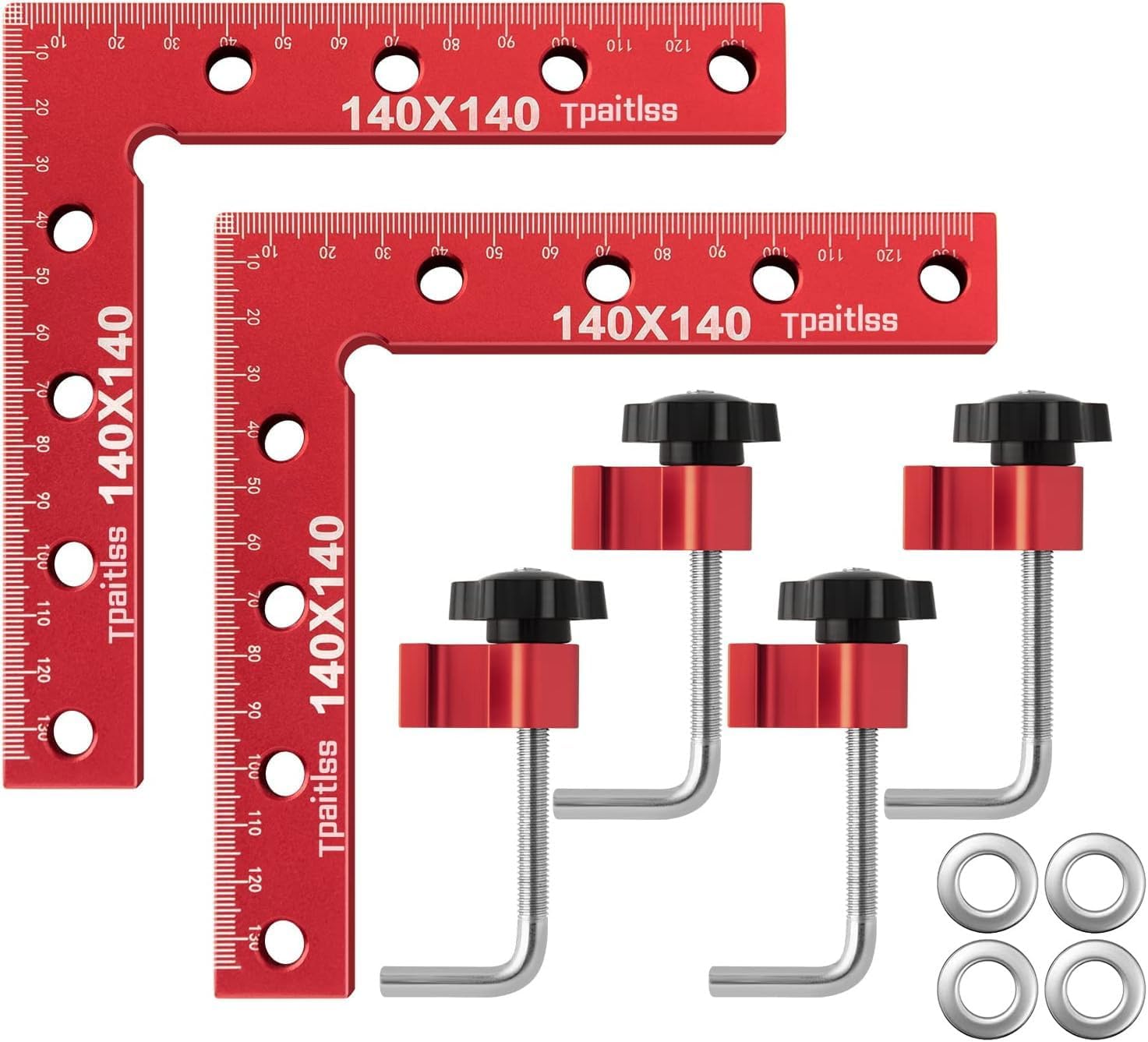

Corner Clamps for Woodworking Aluminum Alloy 90 degree Positioning Square

Check on AmazonKey Specs

- CNC-machined aluminum alloy for durability

- 5.5-inch (140 mm) scale with metric and imperial measurements

- Works with wood boards up to 1-9/16″ thick

- Beveled edges for easy handling

- Suitable for framing, picture frames, and cabinet making

The tpaitlss Corner Clamp is a top-tier tool for woodworking precision. Made from CNC-machined aluminum alloy, it ensures durability and resistance to corrosion, providing long-term service. The inclusion of both metric and imperial measurement units with laser-engraved scales makes it incredibly user-friendly, perfect for accurate and clear readings. The beveled edges allow for easy handling without damaging the wood, and its solid construction ensures no deformation under pressure. Ideal for framing, cabinets, and more, this clamp is an essential tool for any woodworker.

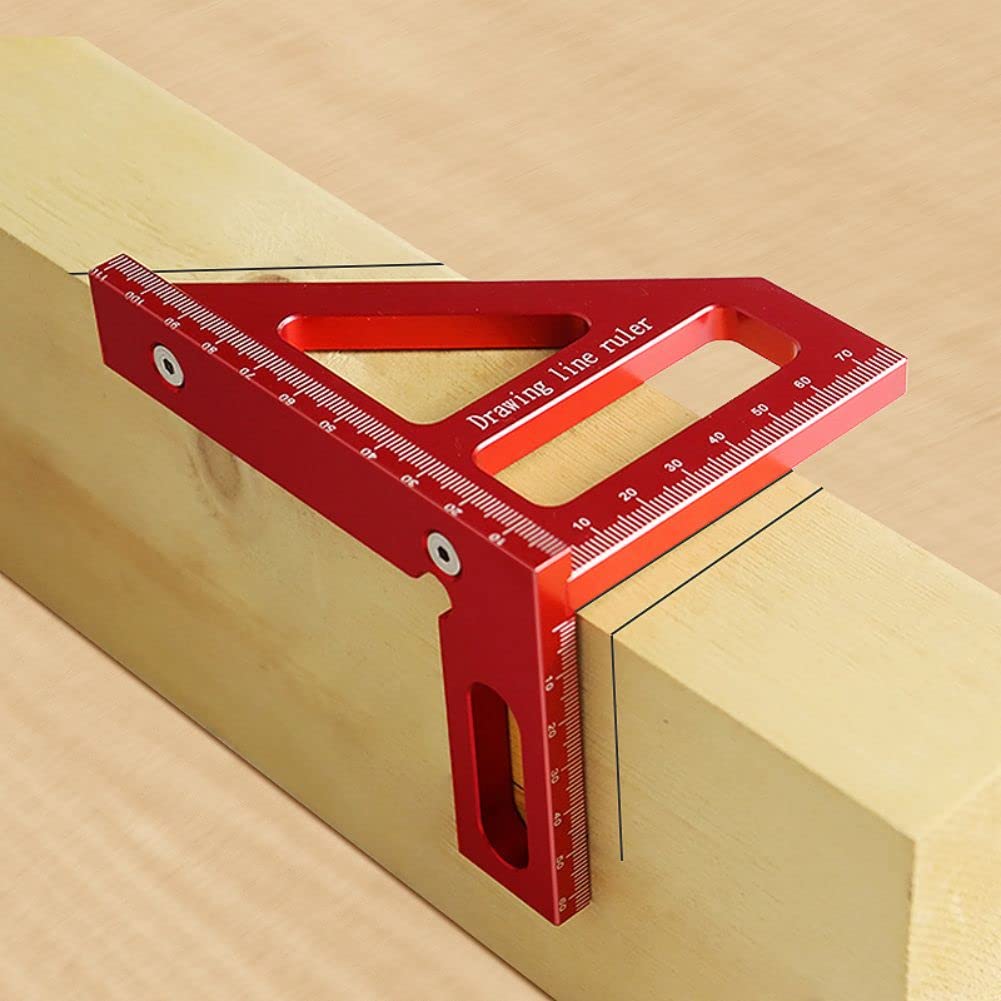

3D Multi-Angle Measuring Ruler,45/90 Degree Aluminum Alloy Woodworking Square

Check on AmazonKey Specs:

- Made of high-quality aluminum alloy

- Measures 45° and 90° angles

- Anodized surface for wear resistance

- 4.4-inch maximum scale (112 mm)

- Includes hexagon screw and Allen wrench for assembly

The KETIPED 3D Multi-Angle Measuring Ruler is an essential tool for precise measurements in woodworking and DIY projects. Made from aluminum alloy, it combines strength with lightness, ensuring durability and corrosion resistance. The versatile design allows for 45 and 90-degree measurements and can be used for scribing, marking, and correcting. Its anodized surface ensures accuracy by maintaining scale precision even under frequent use. This tool is ideal for carpenters, engineers, and DIY enthusiasts working with wood, pipes, or round materials.

IRWIN Tools Combination Square

Check on AmazonKey Specs:

- Cast-zinc body for durability

- Stainless-steel blade for rugged use

- Precision-etched black scales for 90° and 45° readings

- 6-inch length

- Graduation range: 1/16 inches

The IRWIN Tools Combination Square is a robust tool designed for precise measurements. Featuring black, precision-etched scales, it delivers accurate 90° and 45° readings every time. The combination square’s cast-zinc body ensures durability, making it resistant to wear and tear, while the stainless-steel blade stands up to tough jobs. Whether you’re a professional or DIY enthusiast, this 6-inch square is perfect for a variety of woodworking and metalworking tasks. It’s reliable, easy to use, and built for longevity.

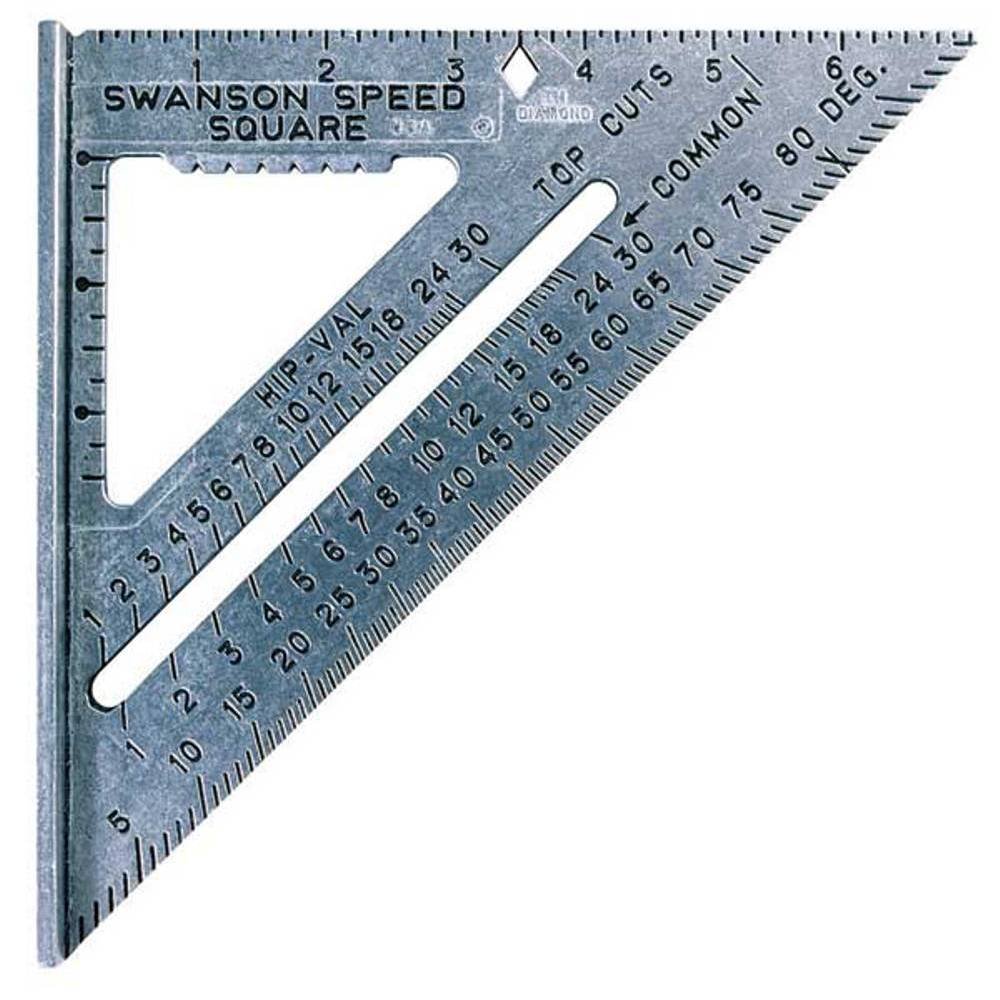

SWANSON Tool Co S0101 7 Inch Speed Square

Check on AmazonKey Specs:

- 7-inch speed square for precise angle marking

- Multiple gradations for hip, valley, and jack rafters

- Includes the Swanson Blue Book for angle cuts

- 1/4-inch spaced scribing notches for easy rafter seat cuts

- Made in the USA since 1925

The SWANSON Tool Co S0101 7 Inch Speed Square is a must-have for anyone who requires precision in their cuts and angles. This versatile tool combines five essential features: a try square, miter square, saw guide, line scriber, and protractor. It simplifies tasks like marking rafters and angles with its easy-to-read, black gradations on a non-glare matte surface. The included Swanson Blue Book provides detailed instructions, making it a fantastic tool for both professionals and DIYers. Durable and practical, this speed square ensures accuracy in every project.

Milescraft 8409 MC-Square150 Imperial Framing Square

Check on AmazonKey Specs:

- 6-inch square with 1/4-inch notch spacing

- Quick angle finders for 30° and 45° angles

- Elongated notches for precise line scribing

- Anodized aluminum construction with 3mm thickness

- Inside and outside scales for versatile measurements

The Milescraft 8409 MC-Square150 Imperial Framing Square is a precision tool designed for framing, woodworking, and general construction. Crafted from anodized aluminum, it boasts durability and resistance to wear. With inside and outside scales, it allows for accurate measurement and marking on both sides of your workpiece. The square includes quick angle finders for 30° and 45° angles, plus elongated notches for precise line scribing. The 6-inch square with 1/4-inch notch spacing ensures precision, making it an excellent tool for any project.

The Ultimate Guide to Woodworking Squares: Common Mistakes and How to Avoid Them

Introduction

As a woodworking enthusiast, you know that precision is key to creating beautiful and functional pieces. One of the essential tools in your arsenal is the woodworking square. Woodworking squares help ensure that your cuts are accurate, corners are square, and joints fit perfectly. Understanding how to use and maintain these tools is crucial for the success of your projects.

Not Checking for Squareness

Achieving squareness in woodworking is vital for seamless assembly and professional results. To check for squareness, place the square against a known straight edge and mark a line. Flip the square and repeat the process. If the lines match up, your square is accurate. Always invest in high-quality squares to avoid inaccuracies that can lead to costly mistakes in your projects.

Tips for Checking for Squareness:

| Tip | Description |

|---|---|

| Use a Reliable Straight Edge | Ensure the edge you are testing against is straight and smooth. |

| Mark and Flip Method | Consistently mark and flip the square to verify accuracy. |

Using a Damaged Square

Using a damaged square can result in inaccurate cuts and compromised woodworking projects. Inspect your square regularly for signs of damage such as dents, bends, or rust. If damage is detected, refrain from using the square to prevent errors in your work.

Steps to Take if a Square is Found to be Damaged:

- Assess the Extent of Damage

- Consider Repair or Replacement

- Label the Square as Unusable

Ignoring Calibration

Calibration ensures that your woodworking square is accurate and reliable. Regularly calibrating your squares is essential to maintain precision in your work. Calibration involves adjusting the square to ensure it provides accurate measurements and angles.

How to Calibrate a Woodworking Square Properly:

- Use a Reference Square

- Adjust the Square as Needed

- Verify Accuracy with Test Cuts

Incorrect Placement of the Square

Improper placement of the square on wood can lead to skewed cuts and misaligned joints. Ensure that the square is flush against the edge of the wood and held firmly in place before marking or cutting. Taking the time to position the square correctly will result in precise and clean cuts.

Tips for Ensuring Proper Placement of the Square:

| Tip | Description |

|---|---|

| Use Clamps for Stability | Secure the square in place with clamps to prevent movement. |

| Double-Check Alignment | Verify that the square is parallel to the edge before marking or cutting. |

Not Maintaining the Square

Neglecting the maintenance of your woodworking square can lead to decreased accuracy and performance. To keep your square in top condition, regularly clean it after use, store it in a dry place to prevent rust, and periodically lubricate any moving parts. Proper maintenance will extend the life of your square and ensure consistent results.

Tools and Techniques for Keeping Squares in Good Condition:

- Use a Soft Cloth for Cleaning

- Apply a Light Coat of Lubricant

- Store in a Dry Environment

Conclusion

In conclusion, woodworking squares are indispensable tools for any woodworker, but their effectiveness relies on proper usage and maintenance. By avoiding common mistakes such as neglecting calibration, using damaged squares, or incorrect placement, you can elevate the quality of your woodworking projects and achieve precise results consistently. Remember, investing time in understanding and caring for your woodworking squares will pay off in the long run.

FAQ Section

How often should I calibrate my woodworking square?

A: It is recommended to calibrate your woodworking square every few months or whenever you notice inconsistencies in your cuts.

Can I repair a damaged woodworking square myself?

A: Minor damages like rust or light dents can often be repaired at home using sandpaper or rust remover. However, for significant damage, it’s best to consult a professional.