Wood gluing is essential for creating strong, durable bonds in woodworking projects. Whether you’re assembling furniture, crafting intricate designs, or making repairs, the right wood glue ensures seamless joints that hold up over time. Unlike nails or screws, glue bonds the wood at a molecular level, providing a solid connection that’s often stronger than the wood itself.

Available in different formulations, such as PVA (polyvinyl acetate), polyurethane, and epoxy, wood glues are designed for specific applications, from indoor projects to heavy-duty outdoor repairs. Most wood glues are easy to apply, set quickly, and can be sanded or painted once dry.

When it comes to woodworking, the right glue makes all the difference in the quality and longevity of your creations. Choose a reliable wood glue and make sure every piece fits together securely.

Our Top Wood Gluing Picks

Titebond III Wood Glue

Check on AmazonKey Specs

- Brand: Titebond, known for quality wood adhesives.

- Specific Uses: Tailored for woodworking applications.

- Material Compatibility: Perfect for bonding wood to wood, ensuring reliable and long-lasting results.

- Form: Liquid, easy to apply with a smooth consistency.

- Weight: Weighs 0.417 lb, convenient for handling and storage.

- Color: Tan, blending well with wood for a natural finish.

- Country of Origin: Manufactured in China.

Titebond III Wood Glue is a high-performance adhesive designed specifically for woodworking projects. It provides strong, durable bonds for various types of wood, making it ideal for both professional woodworkers and DIY enthusiasts.orking.

Titebond Original Wood Glue

Check on Amazon

Key Specs:

- Brand: Titebond, trusted in the woodworking industry.

- Specific Uses: Ideal for woodworking, repair, and furniture applications.

- Material: Made from Polyvinyl Acetate (PVA) for a durable and flexible bond.

- Compatible Material: Wood to wood bonding, providing a superior hold.

- Item Form: Liquid, making it easy to apply.

Titebond Original Wood Glue is a high-quality adhesive designed for woodworking and various repair applications. Ideal for furniture making, general woodwork, and more, it offers fast, strong bonds that are perfect for both professional and DIY projects.

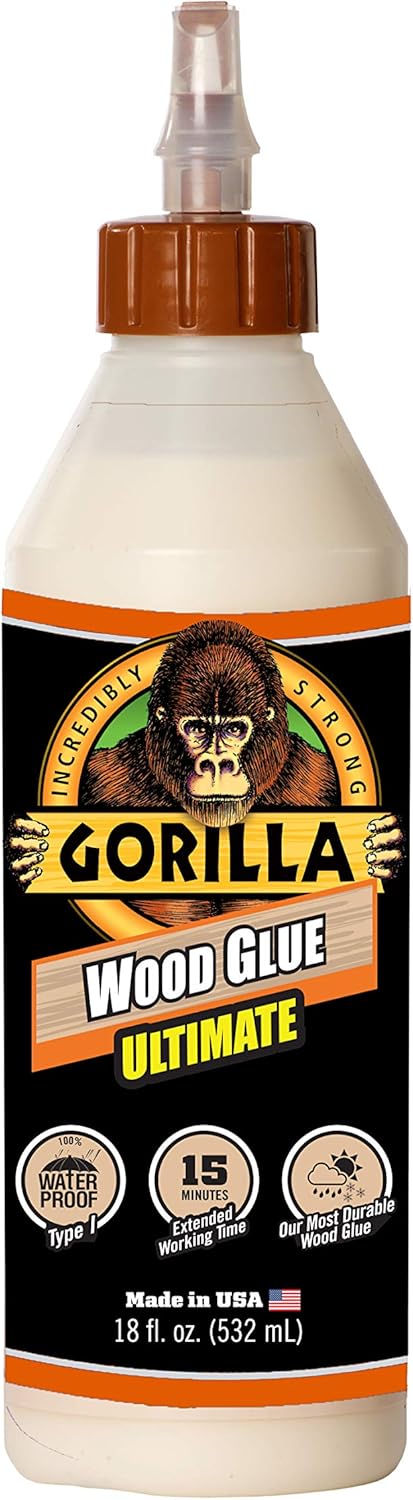

Gorilla Ultimate Waterproof Wood Glue

Check on AmazonKey Specs:

- Brand: Gorilla, known for durable adhesives.

- Specific Uses: Ideal for both indoor and outdoor projects, suited for professional and amateur woodworkers.

- Material: Polyvinyl Acetate (PVA), ensuring a strong, durable bond.

- Compatible Material: Wood and natural wood composites, making it versatile for different types of wood.

- Item Form: Foam, which provides an easy application and clean finish.

Gorilla Ultimate Waterproof Wood Glue is a top-tier adhesive for both professional and amateur woodworkers, designed for both indoor and outdoor use. This high-performance glue offers superior strength and versatility, perfect for various woodworking and repair tasks.

Gorilla Wood Glue

Check on AmazonKey Specs:

- Brand: Gorilla, known for reliable, tough adhesives.

- Specific Uses: Perfect for woodworking, crafting, and repairs.

- Material: Polyvinyl Acetate (PVA), ensuring a strong and lasting bond.

- Compatible Material: Wood, suitable for hardwoods, softwoods, and wood composites.

- Item Form: Liquid, offering easy and precise application.

Gorilla Wood Glue is an exceptional adhesive designed for woodworking, crafting, and repairs, providing a strong and durable bond for all your projects.

Titebond 5003

Check on AmazonKey Specs:

- Brand: Titebond, a trusted name in woodworking adhesives.

- Specific Uses: Ideal for woodworking, especially for exterior applications.

- Material: Polyvinyl Acetate (PVA), known for its strength and reliability.

- Compatible Material: Wood, ensuring a strong bond between wood pieces.

- Item Form: Liquid, allowing for easy application and control.

Titebond 5003 Premium Wood Glue is a high-performance adhesive that ensures strong, durable bonds for woodworking projects, making it an essential tool for professionals and DIY enthusiasts alike.

Introduction

Wood gluing is a crucial aspect of woodworking projects, as it determines the strength and durability of the final piece. Proper wood gluing techniques can make the difference between a sturdy, long-lasting creation and a weak, easily breakable one. In this article, we will explore five common wood gluing mistakes that every woodworker should avoid to ensure successful projects.

Using the Wrong Type of Glue

There are various types of wood glue available, each designed for specific purposes. From PVA glue to polyurethane glue, selecting the appropriate glue for your project is essential for a strong bond. For example, when working on outdoor projects, using waterproof glue like polyurethane is recommended to withstand the elements.

Here’s a quick breakdown of common wood glues:

| Glue Type | Best For |

|---|---|

| PVA Glue | Indoor projects |

| Polyurethane Glue | Outdoor projects |

Choosing the right glue ensures that your project stays intact over time, so always match the glue type to the project requirements.

Not Preparing the Wood Surface Properly

Before applying glue, it’s crucial to prepare the wood surface adequately. A clean and smooth surface allows the glue to adhere properly, creating a strong bond. Steps like sanding the wood, removing any dust or debris, and ensuring a tight fit between pieces are essential for successful gluing.

Common mistakes in wood surface preparation include not removing old glue residue, uneven sanding, or neglecting to clean the surface before applying new glue. These oversights can lead to weak joints and eventual project failure.

- Failure to remove old glue residue

- Uneven sanding of the wood surface

- Neglecting to clean the surface before gluing

By taking the time to properly prepare the wood surface, you set the foundation for a strong and lasting bond between pieces.

Applying Too Much or Too Little Glue

Applying the right amount of glue is crucial for a successful wood gluing project. Using excessive glue can weaken the bond as the excess squeezes out and creates a messy finish. On the other hand, using too little glue results in a weak joint that is prone to breaking under stress.

Guidelines for applying the right amount of glue vary based on the project size and type of wood being used. For larger projects, a generous but not excessive amount of glue is recommended, while smaller projects may require a more delicate touch to avoid excess.

- Effects of using excessive glue on bond strength

- Consequences of using too little glue in wood gluing

- Guidelines for applying the right amount of glue based on project size

By mastering the art of applying the correct amount of glue, you ensure a strong and durable bond between wood pieces.

Not Clamping the Pieces Together Correctly

Clamping plays a vital role in ensuring a strong bond between wood pieces. Proper clamping pressure distributes the glue evenly, creating a secure connection. Common mistakes in clamping include uneven pressure, using the wrong type of clamp for the project, or not allowing sufficient time for the glue to dry.

When selecting clamps, consider the project size and shape to determine the appropriate clamping technique. For larger projects, multiple clamps may be necessary to ensure even pressure across the entire surface.

- Importance of clamping in ensuring a strong bond

- Common mistakes in clamping wood pieces together

- Tips for proper clamping techniques based on project size and shape

By mastering proper clamping techniques, you guarantee a solid bond between wood pieces that will stand the test of time.

Ignoring Wood Grain Direction

Wood grain direction plays a significant role in the strength of glue joints. Ignoring the natural direction of the wood grain can result in weak bonds that are prone to splitting or breaking. When gluing wood pieces together, aligning the grain direction ensures maximum strength and durability.

Consequences of ignoring wood grain direction include joint failure, warping, or uneven stress distribution along the bond. By paying attention to the grain direction and aligning pieces accordingly, you enhance the structural integrity of your woodworking projects.

- Explanation of wood grain direction and its impact on glue joints

- Consequences of ignoring wood grain direction in gluing

- Strategies for aligning wood grain direction for optimal strength

By respecting the natural grain direction of the wood, you create bonds that are not only visually appealing but also incredibly strong and durable.

Rushing the Drying Process

Allowing sufficient time for the glue to dry is crucial for the success of any woodworking project. Rushing the drying process can result in weak bonds that are prone to failure under stress. Different types of wood glue require varying drying times, so it’s essential to follow the manufacturer’s recommendations.

Risks of rushing the drying process include premature handling of the project, which can disrupt the bond and compromise the overall strength. Always exercise patience and give the glue ample time to cure fully before moving on to the next steps in your project.

- Importance of allowing sufficient time for the glue to dry

- Risks of rushing the drying process in wood gluing

- Recommended drying times for different types of wood glue

By respecting the drying times of the glue, you ensure that your woodworking projects are structurally sound and built to last.

Not Cleaning Up Excess Glue

Leaving excess glue on the wood surface can have detrimental effects on the final appearance and integrity of your project. Dried glue residue can interfere with staining or finishing processes, leading to uneven coloration or adhesion issues. It’s essential to clean up excess glue immediately after clamping to avoid these issues.

Consequences of not cleaning up excess glue properly include visible glue lines, rough spots on the surface, or difficulty in achieving a smooth finish. Techniques for removing excess glue without damaging the wood include using a damp cloth or a chisel to carefully scrape away the dried residue.

- Effects of leaving excess glue on the wood surface

- Consequences of not cleaning up excess glue properly

- Techniques for removing excess glue without damaging the wood

By taking the time to clean up excess glue, you ensure a professional-looking finish on your woodworking projects.

Using Old or Expired Glue

The freshness of the glue used in woodworking projects directly impacts the strength and durability of the bond. Using old or expired glue can result in weak joints that are prone to failure over time. Signs that indicate glue has expired include a thickened consistency, unusual odor, or lack of adhesion when tested.

Impact of using old or expired glue on the strength of the bond can lead to project failure, requiring rework or replacement of the affected joints. To prevent this, store wood glue in a cool, dry place away from direct sunlight and periodically test its freshness by conducting a small glue-up test.

- Impact of using old or expired glue on the strength of the bond

- Signs that indicate glue has expired

- Recommendations for storing and testing the freshness of wood glue

By ensuring that your wood glue is fresh and in good condition, you guarantee strong and reliable bonds in your woodworking projects.

Conclusion

Wood gluing is a fundamental aspect of woodworking that requires attention to detail and proper technique. By avoiding common wood gluing mistakes such as using the wrong type of glue, neglecting wood surface preparation, applying incorrect amounts of glue, improper clamping, ignoring wood grain direction, rushing the drying process, not cleaning up excess glue, and using old or expired glue, you can elevate the quality and durability of your projects.

Remember, following proper wood gluing techniques is essential for successful woodworking projects. By applying the tips provided in this article, you can avoid common mistakes and create sturdy, long-lasting woodwork pieces that you can be proud of.

So, grab your tools and get gluing with confidence!

FAQ

What is the best type of glue for outdoor woodworking projects?

For outdoor woodworking projects, it is recommended to use polyurethane glue due to its waterproof properties and ability to withstand the elements.

How can I test if my wood glue has expired?

You can test the freshness of wood glue by conducting a small glue-up test on scrap wood to check for proper adhesion and bond strength.