Depth measurements in woodworking are crucial for ensuring precise cuts, joints, and fitting pieces together seamlessly. Whether you’re drilling, cutting, or shaping wood, accurate depth ensures the structural integrity and aesthetic appeal of your project.

To get it right every time, use the right tools, such as a depth gauge for internal measurements, a combination square for external depth checks, or a drill bit depth stop for consistent hole depth. It’s also important to mark your measurements clearly with a fine pencil or marking knife, ensuring your cuts are spot-on.

Remember, “measure twice, cut once” applies to depth measurements too. For projects that require multiple identical cuts, a stop block can help ensure consistent depth every time. With careful attention to depth, your woodworking projects will be precise, professional, and built to last.

Our Top Depth Measure Picks

Wixey WR25 Mini 3″ Digital Height Gauge for Woodworking

Check on AmazonKey Specs

- Accurate measurement range: 0 to 3.2″ (0-83mm)

- Magnetic feet for stability and positioning

- Locking rule for repeatable accuracy

- ABS and INC modes for precision

- Compact and portable design, includes CR2032 battery

The Wixey WR25 Mini 3″ Digital Height Gauge is designed for woodworkers, offering precise measurements from 0 to 3.2″ (0-83mm) with an accuracy of a thousandth of an inch. Its powerful magnetic feet allow for easy positioning on router tables, while the locking rule ensures repeatable accuracy. Compact and portable, it’s perfect for both DIY enthusiasts and professionals. The digital technology, combined with ABS and INC modes, guarantees precise adjustments for your woodworking tasks.

Milescraft 8601 Depth Gauge – Measure

Check on Amazon

Key Specs:

- Measurement range: 0-50.8mm (0-2 inches)

- Accuracy: +/- 0.1mm

- Durable self-standing frame with wide base feet

- Brass thumb knob for accurate tightening

- Ruler with both inches and millimeters for precise measurements

The Milescraft 8601 Depth Gauge is a versatile tool ideal for setting cutting depths on routers, router tables, and table saws. Its durable self-standing frame with wide base feet ensures stability while measuring. The brass thumb knob allows for precise tightening of the ruler, and the metal ruler displays measurements in both inches and millimeters. The easy-view window enhances accuracy, making it a must-have tool for professionals and DIY enthusiasts alike.

Depth Gauge, Dual Scales Aluminum Alloy Height Gauge

Check on AmazonKey Specs:

- Measuring range: 0-50mm (0-1.97 inches)

- Made from durable aluminum alloy

- Dual scales for height and depth measurements

- Lightweight with a hollow design for improved grip

- Versatile for various woodworking applications

The Depth Gauge with Dual Scales is a versatile tool designed for accurate height and depth measurements. Its aluminum alloy construction ensures durability and resistance to wear, providing long-term reliability. With a measuring range of 0-50mm (0-1.97 inches), it is perfect for applications like woodworking, miter height, and saw blade measurements. Its hollow design enhances grip and reduces weight, making it easy to use. This tool is a great addition for both professionals and DIY enthusiasts.

Depth Measuring Ruler Woodworking Mini Gaps Gauge

Check on AmazonKey Specs:

- Material: Aluminum and metal construction

- Precision: High accuracy for joint and material thickness measurements

- Flexible design for easy use

- Ideal for woodworking, design, and engineering applications

- Color: Red, offering easy visibility and handling

The Depth Measuring Ruler Woodworking Mini Gaps Gauge offers exceptional precision and ease of use for woodworking projects. Crafted with high-quality aluminum and metal, this tool ensures accurate measurements for joint sizes and material thickness. Its flexible design allows for quick, precise gauging, making it an essential tool for woodworkers, designers, and engineers. The gauge’s professional-grade craftsmanship guarantees reliable performance for both simple and complex woodworking tasks.

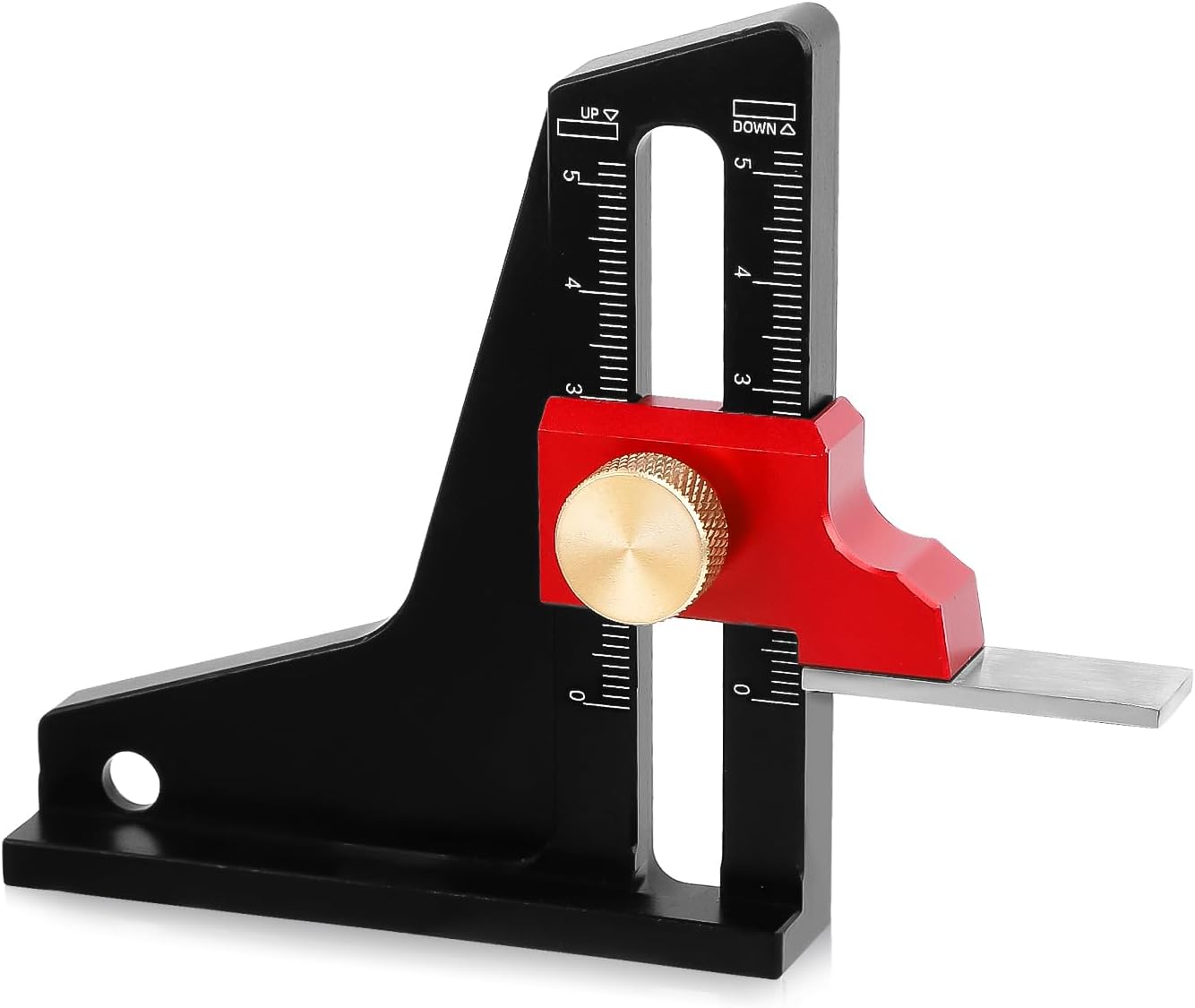

Woodworking Height Gauge

Check on AmazonKey Specs:

- Material: High-quality aluminum alloy

- Dimensions: 11.5×8.5cm/4.53×3.35in

- Dual scale for enhanced precision

- Smooth slider for accurate measurements

- Ideal for measuring gear heights, saw blades, and table drills

The Woodworking Height Gauge is a durable and precise tool designed to meet your daily needs in woodworking. Made of high-quality aluminum alloy, it is tough, scratch-resistant, and offers a comfortable grip. The dual scale enhances measurement precision, while the slider locks smoothly for accurate results. Its portable design makes it easy to store or take with you. Ideal for measuring gear heights, saw blades, table drills, and more, this tool is a must-have for woodworkers.

Achieving Accurate Depth Measurements in Woodworking

Woodworking is a craft that demands precision and attention to detail, especially when it comes to depth measurements. Whether you are cutting joints, drilling holes, or setting up machinery, accurate depth measurements are crucial for the success of your woodworking projects. Inaccurate measurements can lead to misaligned cuts, improper fits, and overall frustration. To help you improve your woodworking skills, here are five essential tips for achieving accurate depth measurements in woodworking.

Understanding the Tools

In woodworking, various tools can be used for depth measurements, including depth gauges, depth stops, and depth rods. Each tool serves a specific purpose and is designed to provide accurate depth readings for different woodworking tasks. It is essential to select the right tool for the job to ensure precise measurements. For example, a depth gauge is ideal for measuring the depth of a hole, while a depth stop is useful for setting the depth of a cut on a router or saw.

To make the right choice, consider the type of woodworking project you are working on and the level of precision required. Investing in high-quality depth measurement tools will not only improve the accuracy of your measurements but also enhance the overall quality of your woodworking projects.

List of Tools Used for Depth Measurements in Woodworking:

| Tool | Purpose |

|—————-|—————————————|

| Depth Gauge | Measures the depth of holes |

| Depth Stop | Sets the depth of cuts on machinery |

| Depth Rod | Provides accurate depth readings |

Calibration of Tools

Before each use, it is crucial to calibrate your depth measurement tools to ensure their accuracy. Calibration helps eliminate any potential errors or discrepancies in the readings, resulting in precise depth measurements. Here is a step-by-step guide to calibrating depth measurement tools:

1. **Check for Zero**: Ensure that the tool is set to zero before taking any measurements.

2. **Use a Calibration Block**: Utilize a calibration block of known thickness to verify the accuracy of the tool.

3. **Adjust if Necessary**: If the tool does not align with the calibration block, make the necessary adjustments to correct the readings.

By following these calibration steps, you can trust that your depth measurement tools are providing accurate and reliable results for your woodworking projects.

Proper Technique for Taking Measurements

Consistency in technique is key to achieving accurate depth measurements in woodworking. The way you position and hold the tool can impact the precision of your readings. To ensure consistent and reliable measurements, follow these steps for taking depth measurements:

1. **Stabilize the Tool**: Secure the tool firmly against the surface to prevent any movement during measurement.

2. **Align Properly**: Position the tool perpendicular to the surface for an accurate depth reading.

3. **Read Carefully**: Take your time to read and record the measurement correctly to avoid errors.

By adopting the correct technique for taking depth measurements, you can enhance the accuracy of your woodworking projects and achieve professional results.

Double-Checking Measurements

Double-checking measurements is a crucial step in woodworking to verify the accuracy of your initial readings. Mistakes can happen, and double-checking ensures that you catch any errors before proceeding with your project. There are several methods you can use to double-check your depth measurements:

1. **Use a Second Tool**: Measure the depth with a different tool to compare the readings.

2. **Visual Inspection**: Inspect the depth visually to see if it aligns with your measurements.

3. **Trial Cuts**: Make test cuts or holes to confirm that the depth is accurate before proceeding with the final work.

By incorporating double-checking into your workflow, you can avoid costly mistakes and achieve precise depth measurements in your woodworking projects.

Dealing with Imperfections in Wood

Wood imperfections such as knots, cracks, and uneven surfaces can pose challenges when taking depth measurements in woodworking. These imperfections can affect the accuracy of your readings and lead to errors in your projects. To overcome these challenges and ensure accuracy in your depth measurements, consider the following strategies:

1. **Surface Preparation**: Smooth out rough surfaces or remove imperfections before taking depth measurements.

2. **Adapt Your Technique**: Adjust your technique to account for imperfections, such as using a different tool or approach.

3. **Take Multiple Measurements**: Take multiple measurements from different angles to account for variations in the wood surface.

By addressing wood imperfections proactively and adapting your approach, you can maintain accuracy in your depth measurements and produce high-quality woodworking projects.

Importance of Lighting

Proper lighting is essential for accurate depth measurements in woodworking. Inadequate lighting can cast shadows, distort readings, and make it challenging to see the depth markings on your tools. To ensure accurate measurements, follow these tips for adequate lighting in your workspace:

1. **Natural Light**: Position your work area near a window to benefit from natural light during the day.

2. **Task Lighting**: Use focused task lighting, such as a desk lamp or overhead light, to illuminate the area where you are taking measurements.

3. **Adjustable Lighting**: Install adjustable lighting options to control the brightness and direction of light based on your needs.

By optimizing the lighting conditions in your workspace, you can improve the visibility of depth measurements and achieve greater accuracy in your woodworking projects.

Avoiding Common Mistakes

In woodworking, several common mistakes can lead to inaccurate depth measurements and compromise the quality of your projects. By being aware of these mistakes and implementing strategies to avoid them, you can enhance the precision of your depth measurements. Here are some common mistakes to watch out for:

1. **Incorrect Tool Selection**: Using the wrong tool for the job can result in inaccurate depth readings.

2. **Inconsistent Technique**: Failing to maintain a consistent technique can lead to varying measurements.

3. **Rushing the Process**: Taking measurements hastily without attention to detail can result in errors.

To avoid these mistakes, take your time, choose the right tools, and focus on maintaining a consistent and careful approach to depth measurements in woodworking.

Using Jigs and Guides

Jigs and guides are valuable tools in woodworking that can help you achieve consistent and accurate depth measurements. These accessories provide support, stability, and precise measurements for a wide range of woodworking tasks. By incorporating jigs and guides into your workflow, you can streamline your processes and improve the quality of your projects. Here are the benefits of using jigs and guides for depth measurements:

– **Consistency**: Jigs and guides ensure consistent depth measurements across multiple pieces.

– **Safety**: Using jigs and guides enhances safety by providing stability and control during cutting or drilling.

– **Efficiency**: Jigs and guides help you work more efficiently by speeding up the setup and measurement process.

To create and use jigs and guides effectively, consider the specific requirements of your woodworking projects and invest in high-quality accessories that align with your needs.

Maintaining Tools for Accuracy

Regular maintenance of your tools is essential for ensuring accuracy in depth measurements in woodworking. Well-maintained tools perform better, provide more reliable readings, and contribute to the overall quality of your projects. To keep your tools in optimal condition for accurate measurements, follow these tips for maintenance:

1. **Cleaning**: Regularly clean your tools to remove dust, debris, and buildup that can affect their performance.

2. **Lubrication**: Apply lubrication to moving parts to prevent friction and ensure smooth operation.

3. **Storage**: Store your tools in a dry and secure environment to protect them from damage and maintain their accuracy.

By incorporating tool maintenance into your woodworking routine, you can prolong the lifespan of your tools and achieve consistent and precise depth measurements in your projects.

Understanding Measurement Units

In woodworking, various measurement units are used to indicate depth, including inches, millimeters, and fractions. Understanding these measurement units and knowing how to convert between them is essential for accurate depth measurements. Different woodworking tasks may require specific measurement units, so being proficient in unit conversion can help you work more effectively. Here is an explanation of different measurement units used in woodworking:

– **Inches**: Commonly used in woodworking for measuring depth, length, and width.

– **Millimeters**: Provides precise measurements and is often used in fine woodworking projects.

– **Fractions**: Used to express measurements in a fractional form, such as 1/4 inch or 3/8 inch.

To convert between different measurement units accurately, use conversion charts or calculators to ensure consistency and precision in your depth measurements.

Importance of Practice

Practice plays a significant role in improving accuracy in depth measurements in woodworking. The more you practice taking measurements, the more familiar you become with your tools, techniques, and processes. Regular practice helps refine your skills, build confidence, and enhance the quality of your woodworking projects. To incorporate practice into your woodworking routines, consider the following suggestions:

1. **Dedicated Practice Sessions**: Set aside time specifically for practicing depth measurements to focus on skill development.

2. **Repetition**: Repeat measurements and tasks to reinforce your understanding and improve your accuracy.

3. **Challenge Yourself**: Take on new and complex projects that require precise depth measurements to push your skills to the next level.

By making practice a priority in your woodworking practice, you can sharpen your abilities, increase your efficiency, and achieve greater accuracy in your depth measurements.

Seeking Feedback

Seeking feedback from experienced woodworkers is a valuable way to improve your depth measurement techniques and enhance your woodworking skills. Constructive feedback can provide insights, suggestions, and tips for refining your approach and achieving better results in your projects. To make the most of feedback from others, consider the following steps:

1. **Ask for Input**: Request feedback from mentors, peers, or woodworking communities to gain different perspectives on your measurements.

2. **Implement Suggestions**: Act on the feedback you receive by incorporating suggested changes or adjustments into your practice.

3. **Continual Learning**: Stay open to learning from others and seek feedback regularly to continue improving your depth measurement techniques.

By actively seeking feedback and using it to refine your skills, you can elevate the quality of your woodworking projects and become a more proficient woodworker.

Troubleshooting Inaccurate Measurements

Despite your best efforts, inaccuracies in depth measurements can still occur in woodworking. Understanding the common reasons for inaccurate measurements and knowing how to troubleshoot and correct them is essential for maintaining precision in your projects. Here are some common reasons for inaccurate depth measurements and steps to address them:

1. **Tool Misalignment**: Check the alignment of your tools and adjust them to ensure they are perpendicular to the surface.

2. **Wear and Tear**: Inspect your tools for signs of wear or damage that may affect their accuracy and replace or repair as needed.

3. **Environmental Factors**: Consider external factors such as temperature or humidity that can impact measurements and make adjustments accordingly.

By identifying and addressing the root causes of inaccuracies in your depth measurements, you can maintain consistency and precision in your woodworking projects.

Conclusion

Achieving accurate depth measurements in woodworking is essential for the success of your projects. By following the five essential tips outlined in this article, including understanding the tools, proper calibration, technique, double-checking measurements, and dealing with imperfections, you can enhance the accuracy and quality of your woodworking projects. Implementing these tips will not only improve your depth measurement skills but also elevate your overall woodworking proficiency. Remember, practice, seek feedback, and strive for precision in every measurement to take your woodworking skills to the next level.

**Call to Action:** Start implementing these tips in your woodworking projects today to see a noticeable improvement in the accuracy of your depth measurements and the quality of your finished pieces.

FAQ

Q: How often should I calibrate my depth measurement tools?

A: It is recommended to calibrate your tools before each use to ensure accurate readings and reliable measurements in your woodworking projects.

Q: What should I do if I encounter imperfections in the wood surface when taking depth measurements?

A: To overcome imperfections in wood surfaces, consider preparing the surface, adapting your technique, and taking multiple measurements from different angles to ensure accuracy.

Q: Why is proper lighting important for depth measurements in woodworking?

A: Adequate lighting is crucial for visibility, accuracy, and precision in depth measurements, as it helps eliminate shadows, enhance clarity, and ensure accurate readings.