Understanding the Importance of Maintaining and Sharpening Blades on a Thickness Planer

Hey there, fellow woodworking enthusiast! Let’s talk about one of the essential tools in your workshop – the thickness planer. This handy device helps you achieve precise thickness on wood pieces, making your projects look polished and professional. However, to keep your thickness planer running smoothly, you need to pay close attention to its blades. Maintaining and sharpening the blades is crucial for optimal performance and quality results.

Our Top Thickness Planer Picks

Dewalt DW735X Thickness Planer

Check on AmazonKey Specs:

- Motor: 15 Amps, 20,000 RPM

- Cutterhead Speed: 10,000 RPM

- Cutting Width: 13 inches

- Material Removal Gauge: Accurate cuts with every pass

- Included: Infeed & outfeed tables, extra knives, dust ejection chute

The DEWALT DW735X Thickness Planer is a powerhouse, with its 15-amp, 20,000 RPM motor, delivering exceptional performance on even larger cuts. The two-speed gear box allows for fine-tuning feed speeds to match material and cutting needs, while the fan-assisted chip ejection keeps the work area clean. I love how the automatic carriage lock reduces snipe and the extra-large turret depth stop simplifies returning to frequently used thicknesses. This machine is incredibly sturdy and efficient, making it a must-have for any serious woodworker.

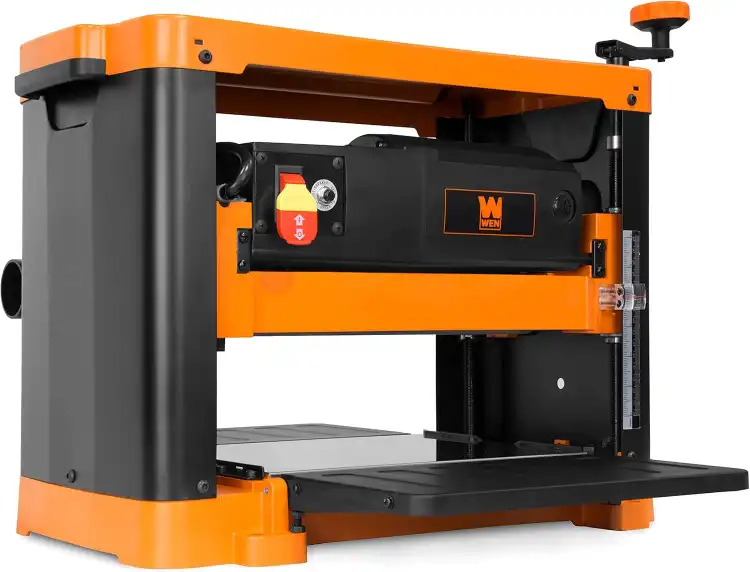

Wen PL1252 Thickness Planer

Check on AmazonKey Specs:

- Motor: 15 Amps, 20,000 cuts per minute

- Cutting Width: 12.5 inches

- Cutting Depth: Up to 1/8 inch per pass

- Dust Port: 2-inch diameter for chip removal

- Weight: 63.9 pounds, portable with rubber-grip handles

The WEN PL1252 12.5-Inch Thickness Planer is a robust, compact tool perfect for smoothing out rough lumber. The 15-amp motor provides impressive power, achieving 20,000 cuts per minute, making quick work of even thick hardwoods. I appreciate the adjustable depth knob, allowing for precise cuts up to 1/8 inch per pass. The infeed and outfeed tables help reduce snipe, and the dust port ensures a cleaner workspace. With easy mobility and solid construction, it’s a great addition to any workshop.

Delta 22-555 Thickness Planer

Check on AmazonKey Specs:

- Motor: 15 Amps, 18,800 cuts per minute

- Infeed/Outfeed Table Dimensions: 6-3/4 in. x 13 in.

- Feed Rate: 28 ft/min

- Cutting Width: 13 inches

- Weight: 57 lbs, Load Capacity 400 lbs

The Delta 13-inch Portable Thickness Planer stands out with its precision machined steel cutterhead and stainless steel bed, ensuring durability and smooth operation. The reversible dust port is a practical feature, allowing you to choose the side for chip collection. I particularly like the nitrile synthetic rubber feed rollers, which provide a secure grip on the workpiece, minimizing slipping. The high feed rate of 28 ft/min makes it efficient for quick planing, while the reversible knives extend its blade life for longer use.

Vevor 1 Thickness Planer

Check on AmazonKey Specs:

- Motor Power: 2000W, 23,500 RPM

- Cutting Width: 13 inches

- Feed Rate: 15-24 ft/min

- Cutting Depth: 0.3 cm

- Weight: 62 lbs

The VEVOR 13-inch Power Benchtop Planer offers impressive power and versatility with its three-blade cutter head and two-speed settings. The 2000W motor ensures smooth cuts, while the quick-change blades and HRC55-60 hardness guarantee long-lasting performance. I love the extended infeed tables for added stock support and the vacuum port for efficient dust removal. With adjustable speeds, it’s perfect for both fast material removal and smooth finishes, making it a reliable tool for any workshop.

Ryobi AP1305 Thickness Planer

Check on AmazonKey Specs:

- Motor: 15 Amps

- Cutting Width: 12.5 inches

- Cutting Depth: 0.13 inches

- Weight: 64.5 lbs

- Infeed/Outfeed Table Length: 31 inches

The RYOBI AP1305 12-1/2-inch Thickness Planer stands out for its precision depth control and powerful 15 Amp motor. The 4-column frame significantly reduces snipe, ensuring a smooth and consistent finish. I appreciate the extra-long infeed and outfeed tables, providing ample material support for larger projects. This planer is perfect for anyone needing reliable, professional-quality results with minimal hassle. With its easy depth adjustments and inclusion of essential tools, it’s a solid choice for woodworkers.

Understanding the Thickness Planer

A thickness planer is a woodworking tool designed to shave off layers of wood to create a consistent thickness across a board. It is commonly used to smoothen rough lumber, reduce the thickness of boards, and ensure uniformity in woodworking projects. The blades in a thickness planer play a vital role in cutting and shaping the wood to the desired thickness.

The components of a thickness planer typically include infeed and outfeed tables, a cutter head with blades, a depth adjustment wheel, and a dust collection system. The blades, positioned in the cutter head, rotate rapidly to trim the wood as it passes through the planer. Properly sharpened blades are essential for achieving precise cuts and a smooth finish on your wood pieces.

Blades in a thickness planer function by shearing off thin layers of wood as the material is fed through the machine. The sharpness of the blades determines the quality of the cut, affecting the surface finish and the overall thickness consistency of the wood. Dull blades can lead to rough surfaces, uneven thickness, and operational issues during planing.

Signs of Dull Blades

How do you know when it’s time to sharpen or replace the blades on your thickness planer? Look out for these telltale signs of dull blades:

- Poor surface finish on wood, with visible tear-out or rough patches.

- Uneven thickness of wood, indicated by variations in the thickness of the material after planing.

- Increased noise and vibration during operation, signaling that the blades are struggling to cut through the wood effectively.

Importance of Maintaining and Sharpening Blades

Maintaining and sharpening the blades on your thickness planer is crucial for several reasons:

- Ensures consistent and smooth cuts, resulting in high-quality woodworking projects.

- Extends the lifespan of the thickness planer by reducing wear and tear on the machine.

- Saves time and money in the long run by avoiding costly repairs and replacements.

Tools and Materials Needed for Maintenance

When it comes to maintaining and sharpening the blades on your thickness planer, you’ll need a few essential tools and materials:

| Tools and Materials |

|---|

| Replacement blades |

| Blade removal tool |

| Cleaning brush |

| Blade sharpening equipment |

Safety Precautions

Before you start maintaining or sharpening the blades on your thickness planer, remember to prioritize safety:

- Always disconnect the power source to prevent accidental starts.

- Wear protective gear such as gloves and safety goggles to shield yourself from any debris.

- Handle the blades with care to avoid cuts or injuries during the maintenance process.

Removing and Inspecting Blades

Now, let’s walk through the process of removing and inspecting the blades on your thickness planer:

- Refer to your planer’s manual for specific instructions on blade removal.

- Check the blades for any signs of damage or wear, such as nicks or dull edges.

- Clean the blades thoroughly before proceeding with sharpening to ensure optimal results.

Sharpening Blades

When it’s time to sharpen the blades on your thickness planer, you have a few options for the sharpening process:

- Consider using a sharpening stone or a specialized blade sharpening machine for efficient results.

- Ensure the proper blade angle and sharpness to achieve the best cutting performance.

- Follow the manufacturer’s guidelines or seek professional assistance if you’re unsure about the sharpening process.

Replacing Blades

After sharpening the blades, it’s time to reinstall them back into your thickness planer:

- Carefully install the sharpened blades, ensuring they are securely in place.

- Adjust the blade height and alignment according to your planer’s specifications.

- Test the planer after blade replacement to confirm that the blades are cutting effectively.

Regular Maintenance Schedule

To keep your thickness planer in top shape, establish a regular maintenance routine that includes:

- Frequent blade inspection and sharpening based on usage and cutting conditions.

- Cleaning the planer after each use to remove dust and debris that can affect performance.

- Properly storing the planer in a dry and secure location to prevent damage and ensure longevity.

Troubleshooting Common Issues

If you encounter problems even after maintaining and sharpening the blades, consider these common issues:

- Uneven cuts after blade sharpening may indicate improper blade alignment or sharpening technique.

- If your blades become dull quickly, review your cutting depth and material hardness to adjust accordingly.

- Don’t hesitate to seek professional help if you’re unable to resolve operational issues with your thickness planer.

Tips for Prolonging Blade Lifespan

Want to make the most out of your thickness planer blades? Follow these tips:

- Avoid planing hard materials that can quickly dull the blades and cause damage.

- Adjust the cutting depth according to the thickness of the wood to reduce strain on the blades.

- Regularly clean and lubricate your planer to prevent debris buildup and ensure smooth operation.

Benefits of Proper Blade Maintenance

By maintaining and sharpening the blades on your thickness planer, you can enjoy a range of benefits:

- Consistent and high-quality woodworking results that showcase your craftsmanship.

- Increased efficiency and productivity in your projects with smoothly planed wood surfaces.

- Cost savings on frequent blade replacements by extending the lifespan of your planer blades.

Conclusion

Remember, a well-maintained and sharpened set of blades is the key to unlocking the full potential of your thickness planer. By following a regular maintenance routine and sharpening schedule, you can ensure that your woodworking projects turn out beautifully every time. So, grab those tools and get your blades in top shape for your next woodworking masterpiece!

References

For more information on maintaining and sharpening blades on a thickness planer, check out the following resources:

- Tools for Woodworking Maintenance

- Essential Woodworking Tools

- Cleaning and Maintenance Guides

- Plumbing Tools for Workshop Safety

- Electrician Tools for Power Equipment

FAQ

How often should I sharpen the blades on my thickness planer?

The frequency of blade sharpening depends on how often you use your thickness planer. As a general rule, it’s recommended to inspect and sharpen the blades every 10-15 hours of use for optimal performance.

Can I sharpen the blades of my thickness planer without removing them?

While it’s possible to sharpen some planer blades without removing them, it’s usually more effective to take the blades out for proper sharpening. This allows you to inspect the blades thoroughly and ensure they are sharpened evenly.

What should I do if I notice chips or nicks on my planer blades?

If you see chips or nicks on your planer blades, it’s essential to address them promptly. You can use a fine file or sandpaper to remove minor imperfections. For more significant damage, consider replacing the blades for optimal cutting performance.