Table saw fences are an indispensable tool in the world of woodworking. They provide stability, precision, and safety, making them a crucial component for any woodworker, whether a seasoned professional or a DIY enthusiast. This article aims to delve into the importance of table saw fences, their types, and factors to consider when purchasing one.

Understanding the role and significance of a table saw fence can greatly enhance your woodworking experience. This guide will provide you with a comprehensive understanding of table saw fences, their importance, and how to choose the right one for your needs.

By the end of this article, you will have a thorough understanding of the different types of table saw fences, their features, and how to maintain them. We will also provide a detailed review of the top table saw fences available in the market today.

Our Top Table Saw Fence Picks

BOW Products 36” XT XTENDER Fence

Check on Amazon

Key Specs

- Height: 5 inches

- Material: Durable aluminum with anodized finish

- Slots: Three T-slots for accessories and custom setups

- Attachment: Compatible with Delta UniFence and Harvey fences

- Compatibility: Works with optional XT Feed Supports for expanded table surface

The BOW Products 36” XT XTENDER Fence is the perfect addition to any saw setup, extending both the fence and the table surface for enhanced control, safety, and stability. Its 5-inch height and T-slots offer versatile feed control options, making it ideal for portable jobsite saws, benchtop saws, and bandsaws. This aluminum extrusion fence, paired with optional XT Feed Supports, ensures smoother cuts and more accurate results. With easy attachment via T-Track Clamps, it’s a quick solution for improving your woodworking workflow.

BOW Products FencePRO FP4

Check on Amazon

Key Specs:

- Material: EVA (closed-cell, non-marring)

- Kickback Resistance: 5x greater than plastic or wood feathers

- Travel Slot: 4 inches

- Mounting: Fits T-Tracks with T-Bolts (1/4″ to 3/4″)

- Feather Reversibility: Reversible and replaceable feathers for long-lasting use

The BOW Products FencePRO FP4 is a game-changer for woodworking, providing exceptional kickback prevention and superior feed control. The innovative EVA material combined with a living hinge design absorbs kickback forces, offering five times more resistance than traditional plastic or wood feathers. It ensures a smoother glide, reduces vibration for cleaner cuts, and is safe on all materials, including the softest woods. Plus, its reversible and replaceable feathers won’t harm blades or router bits, making it a must-have for any woodworker.

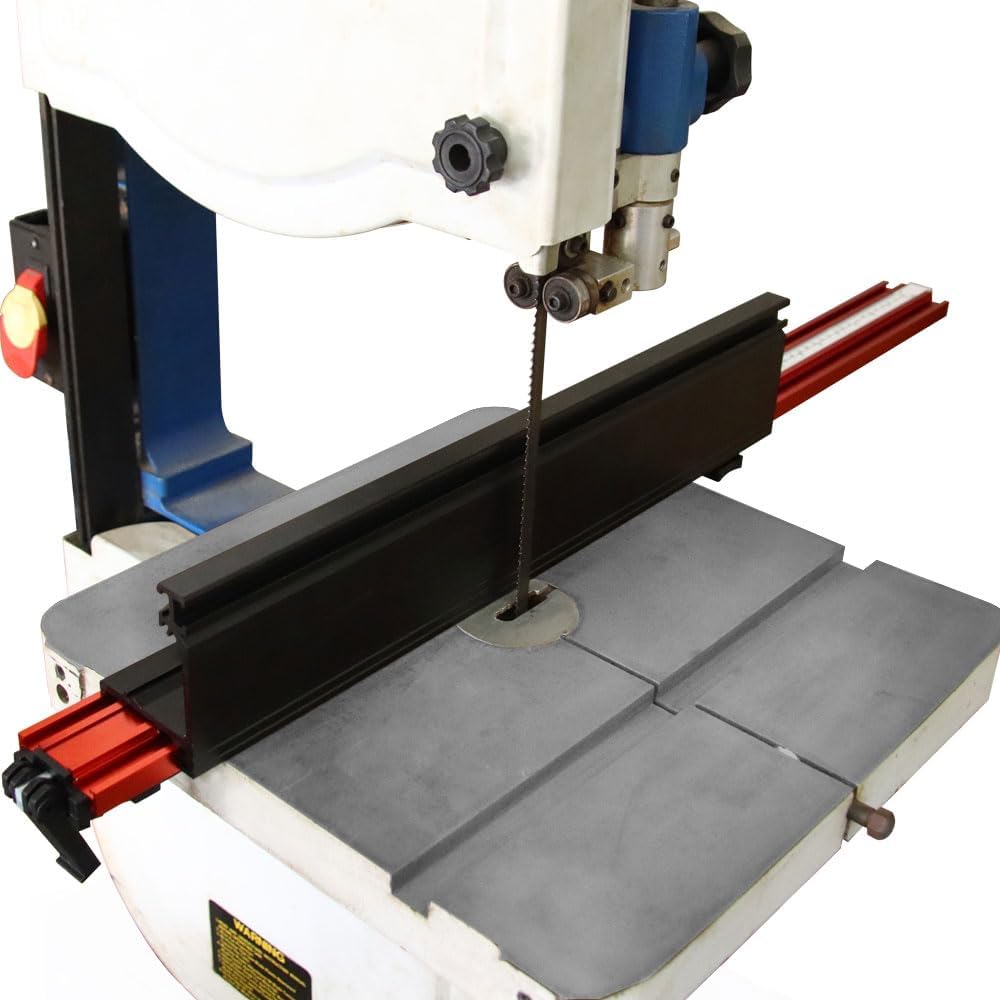

O’SKOOL 24 inch Straight Edge Guide Clamp with Band Saw Fence

Check on AmazonKey Specs:

- Length: 24 inches

- Adjustability: Adjustable fence for varying cut widths

- Setup: Quick-release mechanism for easy attachment

- Material Support: Suitable for thin to thick stock cuts

- Angle Adjustment: Allows slight angle adjustments to compensate for saw blade drift

The O’SKOOL 24-inch Straight Edge Guide Clamp with Band Saw Fence is an excellent tool for ensuring accuracy and precision in your cuts. It helps maintain consistent straight cuts by guiding your workpiece parallel to the cutting path. With an easy setup, the clamp features a quick-release mechanism, saving time during transitions. Adjustable to different distances from the blade, it enhances versatility. Coupled with the PROGRIP clamp, it ensures a secure and stable cutting experience, even allowing slight angle adjustments for improved alignment.

POWERTEC BS900RF Rip Fence

Check on AmazonKey Specs:

- Compatibility: Fits most 9″ band saws (POWERTEC BS900 and others)

- Adjustment Range: Clamping range of 11-3/8” to 12”

- Material: Heavy-duty aluminum for durability

- Locking Mechanism: Cam-lever for easy adjustments

- Setup: No rails required for quick attachment

The POWERTEC BS900RF Rip Fence is designed for wide compatibility with most 9″ band saws, including popular models from WEN, Ryobi, and Delta. It offers a stable and secure setup, ensuring accurate, parallel cuts. The adjustable length feature allows for easy customization, from 11-3/8” to 12”. The easy-locking mechanism with a handy cam-lever enables quick adjustments for precise placements. Built from heavy-duty aluminum, this fence is durable and ideal for consistent performance, though it’s best suited for band saws with table tops up to 9/16” thick.

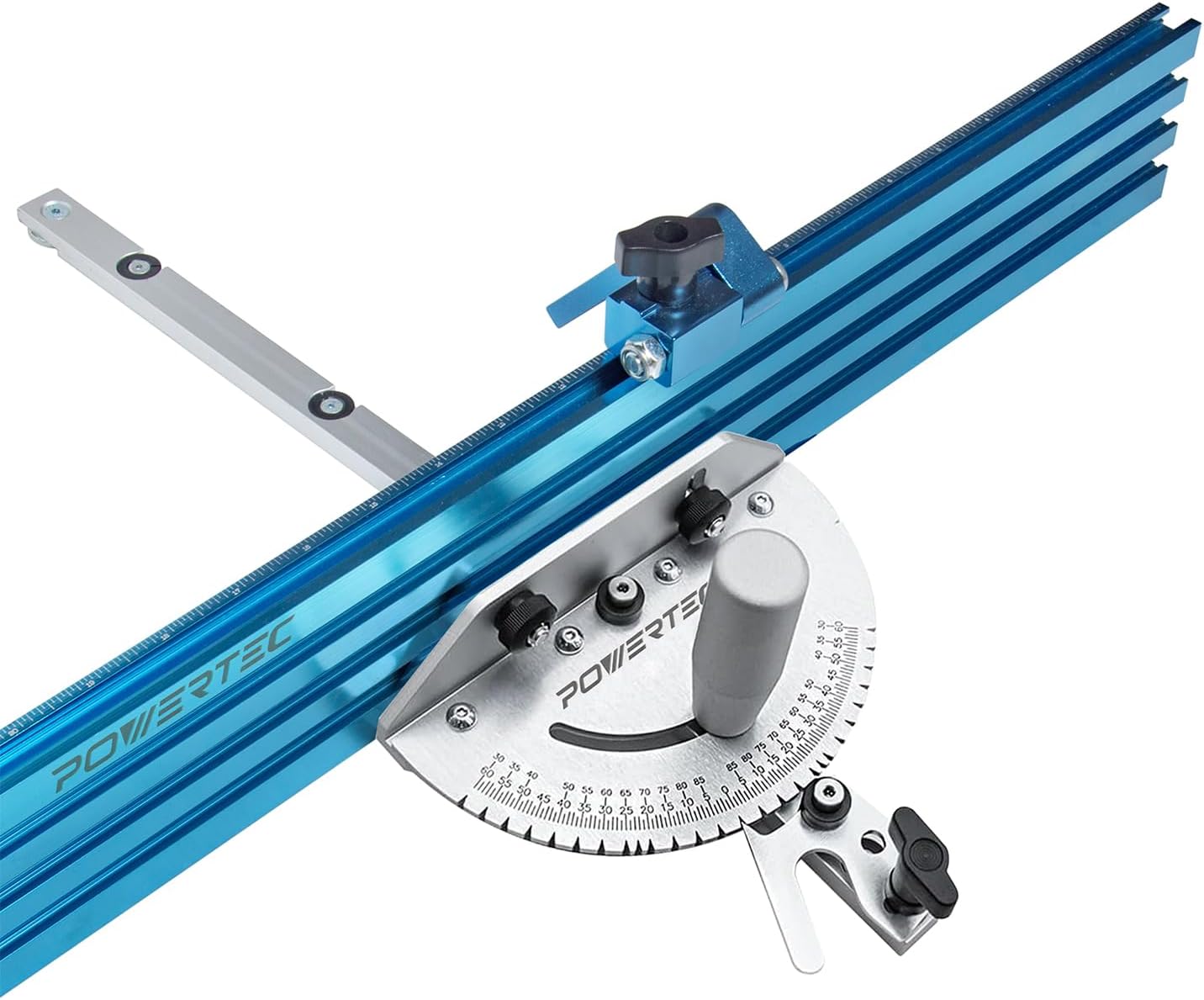

POWERTEC 71391V Fence

Check on Amazon

Key Specs:

- Miter Gauge: 27 angle stops, including 0°, 10°, 22½°, 30°, and 45°

- Track Compatibility: Works with 1/4″-20 hex bolts, 1/4” T-bolts, and 5/16” T-bolts

- Miter Saw Flip Stop: Tool-free, adjustable, quick-change mechanism

- Material: Extruded aluminum profile for durability

- Measuring Scale: Laser-engraved for precision cutting

The POWERTEC 71391V Fence offers a cost-effective 3-piece set that enhances your precision cutting. It includes a high-precision miter gauge with 27 angle indexing stops, ensuring accurate cuts at common angles like 0°, 10°, and 45°, plus many others. The multi-track miter fence features a smooth, laser-engraved measuring scale and is compatible with various bolts and T-track accessories. The included miter saw flip stop provides exceptional cut-length control with a tool-free locking mechanism, making adjustments quick and easy for both left and right cuts.

Understanding Table Saw Fences

A table saw fence is a guide that helps in making straight cuts on a table saw. It is a straight edge parallel to the direction of the cut being made. The fence is set up on one side of the blade and helps to keep the workpiece in place during the cut.

The role of a table saw fence in woodworking is paramount. It provides stability and precision during the cutting process. It ensures that every cut you make is straight and accurate, thereby reducing waste and increasing efficiency. Without a fence, making precise cuts would be a challenging task.

Furthermore, a table saw fence also enhances safety during woodworking. It keeps the workpiece securely in place, preventing it from moving or kicking back during the cut. This significantly reduces the risk of accidents and injuries.

Importance of Enhanced Cutting Accuracy

Cutting accuracy in woodworking refers to the precision of the cuts made on a workpiece. It is the ability to make exact, straight cuts according to the measurements and plans. Enhanced cutting accuracy means making cuts with utmost precision, without any deviations or errors.

Enhanced cutting accuracy in woodworking has numerous benefits. It ensures that the pieces fit together perfectly, resulting in a high-quality finished product. It also reduces waste, as precise cuts mean less material is wasted. This can save both time and resources in the long run.

Moreover, enhanced cutting accuracy can also increase efficiency and productivity. With precise cuts, less time is spent on correcting errors or reworking pieces. This allows for more time to be spent on other aspects of the project, thereby speeding up the overall process.

Types of Table Saw Fences

There are several types of table saw fences available in the market, each with its unique features and benefits. One of the most common types is the T-square fence. This type of fence is known for its durability and accuracy. It features a T-shaped design that provides excellent stability and precision during the cutting process.

Standard fences, on the other hand, are simple and straightforward. They are easy to use and are ideal for beginners or those who prefer a no-frills approach to woodworking. Despite their simplicity, standard fences still provide a high level of accuracy and stability.

Rip fences are another type of table saw fence. They are specifically designed for making rip cuts, which are cuts made along the grain of the wood. Rip fences are adjustable, allowing for a wide range of cut widths. They are also known for their robust construction and high level of accuracy.

Factors to Consider When Buying a Table Saw Fence

When buying a table saw fence, there are several factors to consider. The material and build quality of the fence is crucial. A fence made from high-quality materials will be more durable and reliable. It should also be sturdy and robust to withstand the rigors of regular use.

The length and rip capacity of the fence is another important factor. The length should be sufficient to accommodate the size of the workpieces you typically work with. The rip capacity, on the other hand, refers to the maximum width of cut the fence can handle. It should be large enough to meet your cutting needs.

Other factors to consider include the ease of installation and adjustment, and compatibility with your table saw. The fence should be easy to install and adjust, allowing for quick and easy changes between cuts. It should also be compatible with your table saw to ensure a secure and stable fit.

Detailed Review of Top Table Saw Fences

In this section, we will provide a detailed review of the top table saw fences available in the market today. We will cover top brands and models, highlighting their features and benefits. This will help you make an informed decision when purchasing a table saw fence.

Each model has its unique features and benefits. Some models may offer superior accuracy and precision, while others may be known for their robust construction and durability. It’s important to understand these features and how they can benefit your woodworking projects.

However, each model may also have potential drawbacks. These could include issues with installation, adjustment, or compatibility with certain table saws. Understanding these potential drawbacks will help you choose a model that best suits your needs and avoids any potential issues.

How to Install a Table Saw Fence

Installing a table saw fence is a straightforward process, but it requires careful attention to detail. In this section, we will provide a step-by-step guide to installing a table saw fence. This will include preparing the table saw, aligning the fence, and securing it in place.

However, there are common installation mistakes that you should avoid. These include not properly aligning the fence, not securing it tightly, or not checking for compatibility with your table saw. By avoiding these mistakes, you can ensure a successful installation and optimal performance of your table saw fence.

Maintaining Your Table Saw Fence

Maintaining your table saw fence is crucial for its longevity and performance. This includes routine maintenance such as cleaning and lubricating the fence, checking for wear and tear, and making necessary adjustments.

However, you may encounter common issues with your table saw fence over time. These could include issues with alignment, stability, or wear and tear. In this section, we will provide troubleshooting tips for these common issues, helping you to keep your table saw fence in optimal condition.

Safety Precautions When Using a Table Saw Fence

Safety should always be a priority when using a table saw fence. There are basic safety rules that you should always follow. These include keeping your hands away from the blade, using push sticks or featherboards, and always wearing safety gear.

Speaking of safety gear, it’s important to have the right equipment when using a table saw fence. This includes safety glasses, ear protection, and a dust mask. These items will protect you from potential injuries and health risks associated with woodworking.

Conclusion

In conclusion, a good table saw fence is a crucial tool for any woodworker. It provides stability, precision, and safety, making it an indispensable part of any woodworking project. By understanding the different types of fences, their features, and how to maintain them, you can greatly enhance your woodworking experience.

When buying a table saw fence, consider factors such as material and build quality, length and rip capacity, ease of installation and adjustment, and compatibility with your table saw. Also, remember to always prioritize safety when using a table saw fence.

With the right table saw fence, you can achieve enhanced cutting accuracy, increase efficiency, and produce high-quality woodworking projects. So, invest in a good table saw fence today and take your woodworking skills to the next level.

FAQ

What is a table saw fence?

A table saw fence is a straightedge attached to a table saw that helps guide the material during cutting, ensuring precise, straight cuts.

How does a table saw fence work?

It holds the workpiece securely against the saw blade while keeping it aligned for accurate and consistent cuts.

What are the benefits of using a table saw fence?

It improves cutting accuracy, reduces the risk of accidents, and makes repetitive cuts easier and faster.

Can a table saw fence be adjusted?

Yes, most table saw fences are adjustable, allowing you to change the width of the cut and tailor it to specific measurements.

Are there different types of table saw fences?

Yes, there are various types, including standard fences, T-square fences, and tubular fences, each designed for different cutting tasks and accuracy needs.