Table saw blades are an essential tool for any woodworker or carpenter. They are used to cut through various materials, primarily wood, with precision and ease. The blade is the heart of the table saw, and its performance significantly impacts the quality of your work.

Choosing the right blade for your table saw is crucial for achieving smooth and accurate cuts. The right blade can make the difference between a clean, precise cut and a rough, jagged edge. It can also affect the speed and efficiency of your work.

Understanding the different types of table saw blades and their uses can help you make an informed decision when purchasing a new blade. This article will provide a comprehensive guide to table saw blades, including their components, types, and factors to consider when buying.

Our Top Table Saw Blade Picks

FOXBC 8-1/4 Inch Table Saw Blade

Check on Amazon

Key Specs

- Diameter: 8-1/4 inches

- Number of Teeth: 60

- Kerf: 0.079 inches

- Material: High-density tungsten carbide

- Compatible with: Hardwood, softwood, plywood

The FOXBC 8-1/4 Inch Table Saw Blade is built for precision and longevity. With 60 teeth and an ultra-thin kerf of 0.079 inches, it provides fast, clean, and durable cuts in hardwood, softwood, and plywood. Made from high-density tungsten carbide, this blade resists wear and ensures long-lasting performance. Its 5/8-inch arbor and Diamond Knockout design make it versatile for a wide range of applications, especially in remodeling, demolition, siding, decking, and plywood tasks. This blade is an excellent choice for finish cuts, maintaining clean, efficient performance on the job.

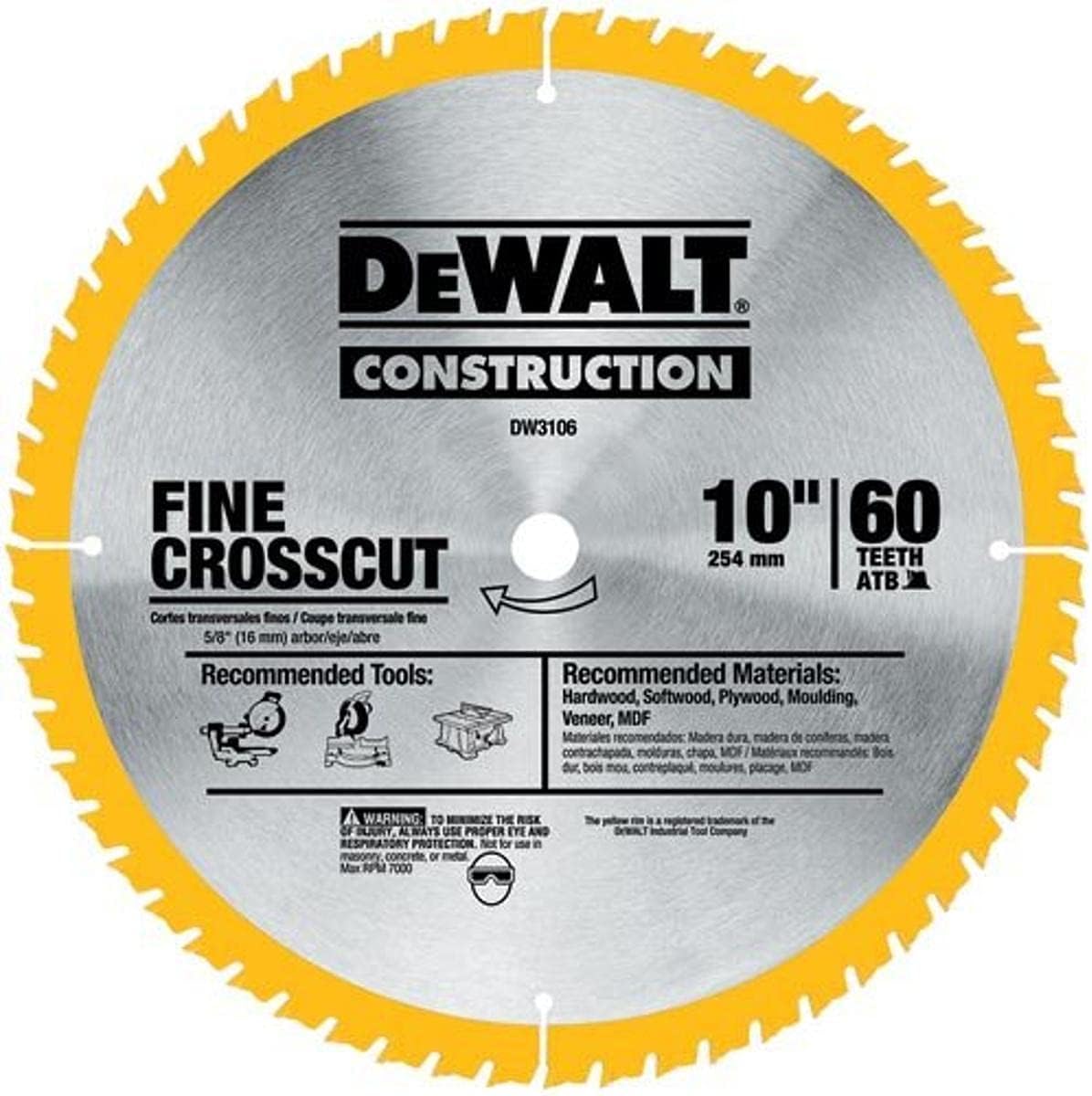

DEWALT 10-Inch Miter/Table Saw Blade

Check on Amazon

Key Specs:

- Diameter: 10 inches

- Number of Teeth: 60

- Material: Blend

- Style: Classic

- Compatible with: Engineered wood

The DEWALT 10-Inch Miter/Table Saw Blade is engineered for precise and efficient cutting. Its thin kerf allows for fast and smooth cuts, making it perfect for engineered wood. The computer-balanced plate reduces vibration, ensuring improved accuracy and a better finish on your projects. The exclusive wedge shoulder design adds more steel behind each tip, boosting the blade’s durability and cutting precision. This blade is designed to handle tough tasks with superior performance, making it an essential tool for woodworking enthusiasts.

SKIL 10″ 28T Saw Blade

Check on AmazonKey Specs:

- Diameter: 10 inches

- Teeth: 28 tungsten carbide teeth

- Grind Type: ATB (Alternate Top Bevel)

- Coating: Clear anti-stick coating

- Application: Suitable for wood, plywood, and composites

The SKIL 10″ 28T Saw Blade is a reliable choice for woodworkers and DIY enthusiasts alike. I particularly like the tungsten carbide teeth, which last up to 60 times longer than standard steel blades, offering exceptional durability. The anti-stick coating resists heat and friction, ensuring smoother cuts and less binding. With its ATB tooth grind, it provides fast, clean cuts in wood, plywood, and composites. Perfect for both rip and cross cuts, this blade is an essential tool for table or miter saws.

Ridge Carbide 10″ 60T, Ultra Combination Table Saw Blade

Check on AmazonKey Specs:

- Diameter: 10 inches

- Tooth Count: 60

- Tooth Geometry: +5° Alternate Top Bevel Grind (ATB)

- Kerf: 0.125 inches

- Bore: 5/8 inches

The Ridge Carbide 10″ 60T Ultra Combination Table Saw Blade offers excellent performance for woodworkers who demand precision and clean finishes. The +5° Alternate Top Bevel Grind (ATB) ensures smooth, fine cuts, especially in plywood, veneered panels, and both hard and soft woods. Its 0.125″ kerf and 0.087″ plate thickness strike a great balance between stability and cutting efficiency. Ridge Carbide blades are renowned for their quality, consistently earning top ratings for the best overall cut in woodworking publications.

Thick Stock Table Saw Rip Blade

Check on Amazon

Key Specs:

- Diameter: 10 inches

- Tooth Count: 20

- Kerf: 1/8 inches (0.125 inches)

- Arbor: 5/8 inches

- Material: American-made alloy steel, carbide-tipped teeth

The Ultra-Shear Thick Stock Table Saw Rip Blade is designed specifically for cutting through dense materials with precision and efficiency. Its optimized tooth and deep curved gullet geometry allows for minimal resistance, making aggressive cuts through thick stock easier and faster. The full kerf design provides maximum stability, ideal for high-powered saws. Made from American-made steel, the blade is meticulously heat-treated, ensuring long-lasting durability and precision in every cut. This saw blade is perfect for those who need a high-performance tool for thick stock ripping.

Understanding Table Saw Blades

The basic components of a table saw blade include the blade plate, teeth, gullets, and arbor hole. The blade plate is the body of the blade, while the teeth do the cutting. The gullets are spaces between the teeth that allow for chip removal, and the arbor hole is where the blade attaches to the saw.

There are several types of table saw blades, each designed for specific tasks. Crosscut blades are used for cutting wood across the grain, rip blades for cutting along the grain, and combination blades can do both. Specialty blades, like dado blades and diamond-tipped blades, are used for specific applications.

Understanding the different types of blades and their uses can help you choose the right blade for your project. For example, if you’re making a lot of crosscuts, a crosscut blade would be the best choice. On the other hand, if you’re cutting a lot of hardwood, a blade with carbide-tipped teeth would be more suitable.

Factors to Consider When Buying Table Saw Blades

When buying a table saw blade, the first factor to consider is the material you will be cutting. Different blades are designed for cutting different materials. For example, a blade designed for cutting wood may not be suitable for cutting plastic or metal.

The type of cut you want to make is another important factor. If you want to make crosscuts, you should choose a crosscut blade. If you want to make rip cuts, a rip blade would be the best choice. For general-purpose cutting, a combination blade would be a good option.

The size of the blade and the number and configuration of its teeth are also important considerations. Larger blades can make deeper cuts, while smaller blades are more suitable for making detailed cuts. Blades with more teeth make smoother cuts, while those with fewer teeth cut faster but less smoothly.

Material of the Blade

Table saw blades can be made from several materials. Steel blades are the most common and are suitable for cutting softwood. However, they can dull quickly when used to cut hardwood.

High-speed steel blades are harder and more durable than regular steel blades. They can cut through harder materials without dulling quickly. Carbide-tipped blades are even harder and can stay sharp for a long time, making them suitable for cutting hardwood and plywood.

Diamond-tipped blades are the hardest and most durable. They are designed for cutting through very hard materials like concrete and tile. However, they are also the most expensive.

Blade Teeth

The teeth of a table saw blade are crucial for its performance. The shape and configuration of the teeth can affect the quality of the cut. Flat top grind (FTG) teeth are used for rip cuts, while alternate top bevel (ATB) teeth are used for crosscuts.

Combination blades use a combination of ATB and FTG teeth, allowing them to make both rip and crosscuts. Triple-chip grind (TCG) teeth are used for cutting hard materials like MDF and laminate.

The number of teeth on a blade also affects its performance. Blades with more teeth make smoother cuts, while those with fewer teeth cut faster. The gullets between the teeth are used to remove the chips produced during cutting.

Blade Size and Diameter

Table saw blades come in various sizes, with the most common being 10 inches in diameter. The size of the blade you choose should depend on the depth of cut you want to make. Larger blades can make deeper cuts, while smaller blades are more suitable for making detailed cuts.

It’s also important to choose a blade size that is compatible with your table saw. The arbor hole of the blade must fit the arbor of your saw. If the hole is too large, the blade won’t fit properly, and if it’s too small, it won’t fit at all.

When choosing a blade size, you should also consider the power of your table saw. Larger blades require more power to spin, so if your saw isn’t powerful enough, it may struggle to spin a large blade at the correct speed.

Blade Kerf

The kerf of a table saw blade is the width of the cut it makes. Blades with a thin kerf remove less material and require less power to cut, making them suitable for smaller, less powerful saws. On the other hand, blades with a full kerf remove more material and require more power, making them suitable for larger, more powerful saws.

Understanding blade kerf is important because it affects the quality of the cut and the amount of waste produced. Blades with a thin kerf make cleaner cuts and produce less waste, while those with a full kerf make rougher cuts and produce more waste.

When choosing a blade kerf, you should consider the power of your table saw and the type of cut you want to make. If your saw is less powerful or you want to make detailed cuts, a thin kerf blade would be a good choice. If your saw is more powerful or you want to make deep cuts, a full kerf blade would be more suitable.

Blade Coating

Some table saw blades are coated to reduce friction and heat, prolonging their lifespan. The most common types of blade coatings are Teflon and titanium. Teflon-coated blades are less likely to accumulate pitch and resin, making them easier to clean. Titanium-coated blades are harder and more durable, allowing them to stay sharp for longer.

The coating of a blade can significantly affect its performance and lifespan. Coated blades tend to cut smoother and stay sharp for longer than uncoated blades. However, they are also more expensive.

When choosing a blade coating, you should consider the type of material you will be cutting and how often you will be using the blade. If you will be cutting a lot of resinous wood or using the blade frequently, a coated blade would be a good investment.

Blade Compatibility

It’s crucial to ensure that the blade you choose is compatible with your table saw. The arbor hole of the blade must fit the arbor of your saw. If the hole is too large, the blade won’t fit properly, and if it’s too small, it won’t fit at all.

Using a blade that is not compatible with your saw can result in poor performance and can even be dangerous. It’s also important to ensure that the blade is suitable for the type of cut you want to make. For example, using a rip blade for crosscuts can result in rough, jagged edges.

When buying a new blade, you should check the manufacturer’s specifications to ensure that it is compatible with your saw. If you’re unsure, you can ask a knowledgeable salesperson or contact the manufacturer for advice.

Safety Considerations

Using a table saw blade safely is crucial to prevent accidents. Some blades come with safety features like anti-kickback teeth, which help to prevent the blade from kicking back and causing injury. Other safety features to look for include a blade guard and a riving knife.

It’s also important to use the blade correctly. You should always wear safety glasses and hearing protection when using a table saw. You should also avoid standing directly behind the blade and keep your hands away from the cutting area.

Regularly inspecting and maintaining your blade can also help to prevent accidents. You should check the blade for damage before each use and replace it if it’s dull or damaged. You should also clean the blade regularly to remove pitch and resin, which can cause the blade to overheat and become dull.

Maintenance and Care of Table Saw Blades

Proper maintenance and care can prolong the lifespan of your table saw blade and ensure that it performs at its best. This includes cleaning the blade regularly to remove pitch and resin, which can cause the blade to overheat and become dull.

You should also inspect the blade regularly for damage. If the blade is dull or damaged, it should be replaced. Using a dull or damaged blade can result in poor quality cuts and can even be dangerous.

When not in use, the blade should be stored in a safe place where it won’t be damaged. It’s also a good idea to have the blade professionally sharpened periodically to ensure that it stays sharp and performs well.

Top Brands for Table Saw Blades

There are many brands that manufacture table saw blades, each with their own strengths and weaknesses. Some of the top brands include Freud, Forrest, Irwin, and DeWalt. These brands are known for their high-quality blades that offer excellent performance and durability.

When comparing brands, it’s important to consider the quality of the blades as well as their price. While some brands may be more expensive, their blades are often made from higher quality materials and offer better performance and longevity.

It’s also a good idea to read reviews and ask for recommendations from other woodworkers or carpenters. This can help you make an informed decision and choose a brand that offers the best value for your money.

Price Range and Where to Buy

The price of table saw blades can vary widely depending on their size, material, and brand. Basic steel blades can be quite affordable, while high-end diamond-tipped blades can be quite expensive. However, investing in a high-quality blade can save you money in the long run, as they often last longer and perform better.

Table saw blades can be purchased at home improvement stores, woodworking supply stores, and online. Buying online can often be more convenient and offer a wider selection, but it’s important to ensure that you’re buying from a reputable seller.

When buying a blade, it’s important to consider not only the initial cost but also the cost of maintenance and replacement. A cheaper blade may seem like a good deal, but if it dulls quickly and needs to be replaced often, it may end up costing more in the long run.

Conclusion

Choosing the right table saw blade is crucial for achieving smooth and accurate cuts. By understanding the different types of blades and their uses, you can make an informed decision and choose the blade that best suits your needs.

Remember to consider factors like the material to be cut, the type of cut desired, the size of the blade, and the number and configuration of its teeth. Also, consider the material of the blade, its kerf, coating, and compatibility with your saw.

By choosing the right blade and using it safely and correctly, you can achieve high-quality cuts and make your woodworking or carpentry projects a success.

FAQ

What is the best table saw blade for hardwood?

Carbide-tipped blades are generally considered the best for cutting hardwood. They are harder and stay sharp longer than steel blades.

How often should I replace my table saw blade?

The frequency of replacement depends on how often you use your saw and what materials you cut. However, if the blade is dull or damaged, it should be replaced immediately.