Scroll saw blades are an essential tool for any woodworker, hobbyist, or DIY enthusiast. The right blade can make the difference between a clean, precise cut and a rough, jagged edge. It can also impact the speed and efficiency of your work. Therefore, understanding the different types of scroll saw blades and how to choose the right one for your project is crucial.

The purpose of this article is to provide a comprehensive guide on scroll saw blades. It will cover everything from the basics of what a scroll saw blade is and its function, to the different types of blades and their uses, factors to consider when buying blades, and even how to maintain and care for your blades. Whether you’re a seasoned professional or a beginner just starting out, this guide will equip you with the knowledge you need to make informed decisions about scroll saw blades.

By the end of this article, you will have a better understanding of scroll saw blades and feel more confident in choosing the right blade for your project. So, let’s dive in and start exploring the world of scroll saw blades.

Our Top Scroll Saw Blade Picks

FOXBC 5-Inch Scroll Saw Blade

Check on AmazonKey Specs

- Material: High Carbon Steel (SK5 Japanese Carbon Steel)

- Teeth per Inch (TPI): 10, 15, 18, 24 (12 TPI Pack)

- Compatible Materials: Wood, Plastic, Copper

- Blade Length: 5 inches

- Pack Quantity: 48 Blades (12-each TPI variety)

The FOXBC 5-Inch Scroll Saw Blade is a highly durable and easy-to-use tool designed for precise cutting of various materials such as hardwood, softwood, plastic, copper, and other soft metals. Made from corrosion-resistant SK5 Japanese carbon steel, it ensures increased strength and longevity for lasting performance. With a pin-end design, this blade is compatible with machines that require 5-inch pin-end blades, offering a perfect replacement for several popular models like WEN, Dremel, TACKLIFE, and more.

Olson Saw FR49501 Pin End Scroll Saw Blade

Check on AmazonKey Specs:

- Material: Metal

- Style: Traditional

- Blade Type: Pin-End

- Dimensions: 8.89 x 21.59 x 2.54 cm

- Weight: 23 grams

The Olson Saw FR49501 Pin End Scroll Saw Blade is crafted for precision cutting and provides outstanding durability for various projects. This blade is designed with high-quality metal and features a traditional style for smooth performance. It is lightweight, weighing just 23 grams, and is ideal for use on a variety of materials, including wood and plastic. The blade’s pin-end design ensures easy installation and compatibility with a wide range of scroll saws.

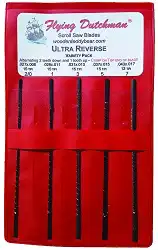

Flying Dutchman Ultra Reverse Five Dozen Scroll Saw

Check on AmazonKey Specs:

- Material: Hardened Steel Alloy

- Blade Length: 5 inches

- Number of Teeth: 15

- Blade Type: Ultra Reverse (reverse every third tooth)

- Included Sizes: #2/0, #1, #3, #5, and #7

The Flying Dutchman Ultra Reverse Five Dozen Scroll Saw blades are made from hardened steel alloy and are known for their precision cutting and longevity. These 5-inch pinless blades are designed with milled edges, which provide a sharper cutting edge for smoother cuts. The reverse tooth design—where every third tooth is reversed—prevents splintering on the underside of projects, making these blades ideal for fine woodworking. Manufactured in Germany, these blades offer fast and smooth cutting while minimizing tear-out, a feature highly appreciated by woodworkers. The pack includes a variety of sizes, catering to different cutting needs.

Jon Bhandari Tools Steel Premium Cut Off Wheel 14 inch Set

Check on AmazonKey Specs:

- Material: Alloy Steel

- Size: 355x3x25.4mm

- Max RPM: 4400

- Package Contents: 5x Cut Off Wheel

- Weight: 3450g (5 pieces)

The Jon Bhandari Tools Steel Premium Cut Off Wheel 14 inch Set offers precise and efficient cutting through a variety of metals, including iron and steel. Designed for durability, these 355x3x25.4mm wheels maintain sharpness for multiple cuts, reducing the need for frequent replacements. With a max RPM of 4400, these wheels deliver consistent performance and smooth operation, minimizing vibrations for enhanced safety and operator comfort. Their compatibility with most 14-inch cut-off machines makes them versatile for numerous industrial and DIY projects.

Bosch SS5-15 Scroll Saw Blade

Check on AmazonKey Specs:

- Material: Premium-grade steel

- Size: 5″

- Number of Teeth: 15

- Compatible Materials: Wood, Plastic, Non-ferrous Metals

- Item Weight: 9.07g

The Bosch SS5-15 Scroll Saw Blade is designed for precise and efficient cutting of intricate shapes in woods, plastics, and non-ferrous metals. Made from premium-grade steel, it ensures long-lasting durability and sharpness. The blade is precision sharpened to provide smooth, clean cuts, and is compatible with both pinned and plain scroll saws. Ideal for users requiring reliable performance in detailed projects, it delivers exceptional value for both professional and DIY applications.

Understanding Scroll Saw Blades

A scroll saw blade is a thin, narrow saw blade used for intricate cutting work. It is most commonly used in a scroll saw, a small electric or pedal-operated saw that is used to cut intricate curves in wood, metal, or other materials. The blade is the heart of the scroll saw, and its design and characteristics can significantly impact the quality of the cut.

There are several different types of scroll saw blades, each designed for a specific type of cut or material. For example, standard tooth blades are the most common and are suitable for a wide range of materials and cuts. Skip tooth blades, on the other hand, are designed for cutting thicker materials and provide a smoother finish. Double tooth blades offer a slower, more controlled cut, while precision ground blades are designed for intricate, detailed work.

Understanding the different types of scroll saw blades and their uses is the first step in choosing the right blade for your project. But there are also several other factors to consider, such as the material you will be cutting, the thickness of the material, the complexity of the design, and the speed at which you want to cut.

Factors to Consider when Buying Scroll Saw Blades

When buying scroll saw blades, the first factor to consider is the material you will be cutting. Different blades are designed for different materials, so it’s important to choose a blade that is suitable for the material you will be working with. For example, if you are cutting wood, you might choose a standard tooth blade, while if you are cutting metal, you might choose a skip tooth blade.

The thickness of the material is another important factor to consider. Thicker materials require a blade with larger teeth, while thinner materials require a blade with smaller teeth. The complexity of the design also plays a role in blade selection. For intricate, detailed designs, a blade with smaller teeth and a narrower kerf (the width of the cut made by the blade) is usually the best choice.

The speed at which you want to cut is also a factor to consider. If you want to cut quickly, a blade with larger teeth will be more efficient. However, if you want a smoother finish, a blade with smaller teeth will be better. Remember, the key is to choose a blade that is suitable for your specific needs and project requirements.

Detailed Analysis of Scroll Saw Blade Types

Standard tooth blades are the most common type of scroll saw blade. They have teeth that are evenly spaced along the length of the blade, making them suitable for a wide range of materials and cuts. These blades are versatile and easy to use, making them a good choice for beginners.

Skip tooth blades, on the other hand, have a gap between each tooth. This design allows the blade to clear sawdust more efficiently, making it a good choice for cutting thicker materials. Skip tooth blades also provide a smoother finish than standard tooth blades.

Double tooth blades have two teeth close together followed by a gap. This design provides a slower, more controlled cut, making these blades ideal for intricate, detailed work. Finally, precision ground blades have smaller, sharper teeth that are ground to a precise shape. These blades are designed for detailed, intricate work and provide the smoothest, most precise cut.

The Importance of Blade Size

Blade size is another important factor to consider when choosing a scroll saw blade. The size of the blade affects the cut in several ways. First, larger blades have larger teeth, which can cut through material more quickly. However, they also produce a wider kerf, which can result in a less smooth finish.

Smaller blades, on the other hand, have smaller teeth and produce a narrower kerf. This makes them ideal for intricate, detailed work, but they may not be as efficient at cutting through thicker materials. Therefore, it’s important to choose a blade size that is appropriate for the material you will be cutting and the type of cut you want to make.

Choosing the right blade size for your project can be a bit of a balancing act. On one hand, you want a blade that is large enough to cut through your material efficiently. On the other hand, you don’t want a blade that is so large it produces a rough, jagged cut. The key is to find a blade that is the right size for your specific needs and project requirements.

Blade Material and Durability

Scroll saw blades are typically made from one of three materials: carbon steel, high-speed steel, or bi-metal. Each material has its own strengths and weaknesses, and the best choice depends on your specific needs and project requirements.

Carbon steel blades are the most common. They are durable and affordable, making them a good choice for most general-purpose cutting tasks. However, they can dull quickly when used to cut harder materials.

High-speed steel blades are more durable and heat-resistant than carbon steel blades, making them a good choice for cutting harder materials. However, they are also more expensive. Bi-metal blades combine the durability of high-speed steel with the flexibility of carbon steel, making them a good choice for a wide range of cutting tasks. However, they are the most expensive type of blade.

The material of the blade affects not only its durability but also its performance. For example, high-speed steel blades can cut through harder materials more efficiently than carbon steel blades. Therefore, it’s important to consider both the durability and performance of the blade when making your selection.

Understanding TPI (Teeth Per Inch)

TPI, or teeth per inch, is a measure of the number of teeth on a saw blade. The TPI of a blade can significantly impact the quality of the cut. In general, blades with a higher TPI produce a smoother cut but cut more slowly, while blades with a lower TPI cut more quickly but produce a rougher cut.

Choosing the right TPI for your project depends on the material you will be cutting and the type of cut you want to make. For example, if you are cutting a thick piece of wood and speed is your primary concern, you might choose a blade with a lower TPI. However, if you are cutting a thin piece of metal and want a smooth, precise cut, you might choose a blade with a higher TPI.

It’s also important to note that the TPI of a blade can affect its durability. Blades with a higher TPI tend to wear out more quickly than blades with a lower TPI, especially when used to cut harder materials. Therefore, when choosing a blade, it’s important to consider both the quality of the cut and the longevity of the blade.

The Role of Blade Tension in Cutting

Blade tension is another important factor to consider when using a scroll saw. Proper blade tension can significantly impact the quality of the cut and the lifespan of the blade. If the tension is too low, the blade can wander or deflect, resulting in an inaccurate cut. If the tension is too high, the blade can break.

Adjusting blade tension can be a bit of a trial-and-error process. The goal is to find a tension that is high enough to keep the blade straight and accurate, but not so high that it causes the blade to break. One common method is to tighten the blade until it “pings” when plucked, then adjust as needed based on the quality of the cut.

Proper blade tension is not only important for achieving a good cut, but also for prolonging the life of your blades. A blade that is consistently tensioned too high or too low will wear out more quickly, resulting in more frequent blade changes and higher costs over time.

Price vs Quality

When it comes to scroll saw blades, there is often a trade-off between price and quality. Higher-quality blades are typically more expensive, but they also tend to last longer and provide a better cut. Therefore, it’s important to consider both the initial cost of the blade and the potential long-term savings when making your selection.

While it can be tempting to opt for the cheapest blades, this can often be a false economy. Cheap blades can dull quickly, resulting in more frequent blade changes and higher costs over time. They can also produce a lower-quality cut, which can impact the final result of your project.

On the other hand, investing in more expensive blades can provide better value in the long run. These blades are typically more durable and provide a higher-quality cut, resulting in fewer blade changes and better results. Therefore, it’s often worth investing in higher-quality blades, especially if you use your scroll saw regularly.

Top Scroll Saw Blade Brands

There are many different brands of scroll saw blades on the market, each with their own strengths and weaknesses. Some of the most popular brands include Olson, Pegas, and Flying Dutchman. These brands are known for their high-quality blades and wide range of options.

Olson is a well-known brand that offers a wide range of blades for different materials and cuts. Their blades are known for their durability and precision, making them a popular choice among professionals and hobbyists alike.

Pegas is another popular brand, known for their high-quality, Swiss-made blades. They offer a wide range of options, including standard tooth, skip tooth, double tooth, and precision ground blades. Flying Dutchman, meanwhile, is known for their high-quality, German-made blades. They offer a range of options, including standard tooth, skip tooth, and double reverse tooth blades.

When comparing different brands, it’s important to consider not only the price but also the features and quality of the blades. Remember, the goal is to find a blade that offers the best value for your specific needs and project requirements.

How to Change a Scroll Saw Blade

Changing a scroll saw blade is a relatively straightforward process, but it’s important to follow the correct steps to ensure your safety and the longevity of your saw. Here is a step-by-step guide on how to change a scroll saw blade:

1. Unplug the saw: Always unplug the saw before changing the blade to prevent accidental activation.

2. Release the tension: Release the tension on the old blade by turning the tension knob or lever.

3. Remove the old blade: Remove the old blade by loosening the blade clamps. Be careful not to lose any small parts.

4. Insert the new blade: Insert the new blade into the blade clamps, making sure the teeth are facing forward and downward.

5. Tighten the blade clamps: Tighten the blade clamps to secure the new blade in place.

6. Adjust the tension: Adjust the tension on the new blade by turning the tension knob or lever. The blade should be tight enough to “ping” when plucked, but not so tight that it breaks.

When changing blades, it’s important to take safety precautions. Always wear safety glasses to protect your eyes from flying debris, and be careful not to cut yourself on the sharp blade. Also, make sure to dispose of old blades properly to prevent injury.

Maintenance and Care for Scroll Saw Blades

Proper maintenance and care can significantly prolong the life of your scroll saw blades. Here are some tips for maintaining and caring for your blades:

1. Clean your blades regularly: Over time, blades can become clogged with sawdust and resin, which can reduce their cutting efficiency. To clean your blades, soak them in a blade cleaner or a solution of warm water and mild detergent, then scrub them gently with a soft brush.

2. Store your blades properly: Store your blades in a dry, cool place to prevent rust. If possible, store them in their original packaging to protect them from damage.

3. Use the right blade for the job: Using the wrong blade for the job can cause the blade to wear out more quickly. Always choose a blade that is suitable for the material you are cutting and the type of cut you want to make.

4. Avoid forcing the blade: Forcing the blade through the material can cause it to dull or break. Always let the blade do the work, and feed the material into the blade at a steady, controlled pace.

By following these tips, you can prolong the life of your blades and get the best possible performance from your scroll saw.

Conclusion

Choosing the right scroll saw blade is crucial for achieving a good cut and getting the best possible performance from your saw. By understanding the different types of blades and their uses, and considering factors such as the material to be cut, the thickness of the material, the complexity of the design, and the speed of the cut, you can make an informed decision and choose the right blade for your project.

Remember, the goal is not to find the cheapest blade, but to find the blade that offers the best value for your specific needs and project requirements. By investing in high-quality blades and taking proper care of them, you can get the most out of your scroll saw and achieve the best possible results.

So, whether you’re a seasoned professional or a beginner just starting out, I hope this guide has provided you with the knowledge and confidence you need to choose the right scroll saw blade. Happy cutting!

Appendix

For additional information or resources related to scroll saw blades, you may want to check out the following:

1. “The Scroll Saw: A Beginner’s Guide.” This book provides a comprehensive introduction to the scroll saw, including how to choose and use scroll saw blades.

2. “Scroll Saw Workbook.” This workbook offers a range of projects that can help you practice and improve your scroll saw skills.

3. “Scroll Saw Blade Selection Chart.” This handy chart provides a quick reference for choosing the right scroll saw blade based on the material and type of cut.

FAQ

What is a scroll saw blade?

A scroll saw blade is a fine-toothed blade used in a scroll saw to cut intricate patterns and curves in wood, metal, or plastic.

How does a scroll saw blade work?

The blade moves up and down rapidly, allowing for precise cutting along detailed lines and curves without splintering the material.

What types of materials can a scroll saw blade cut?

Scroll saw blades can cut wood, plywood, MDF, metal, plastic, and even some soft materials like foam, depending on the blade type.

Are there different types of scroll saw blades?

Yes, scroll saw blades come in different sizes and tooth configurations, such as spiral, straight, and reverse-tooth blades, suited for various cutting tasks.

How do I choose the right scroll saw blade?

Choose a blade based on the material you’re cutting, the intricacy of the cut, and the thickness of the material. Finer blades are ideal for delicate cuts, while coarser blades work better for thicker materials.