A parallel clamp is a versatile tool used in various industries, particularly in woodworking and metalworking. It is a type of clamp that applies pressure across its entire jaw length, ensuring that the workpiece is held securely and evenly. The name ‘parallel clamp’ is derived from its design, where the jaws remain parallel to each other throughout the clamping process.

This tool is characterized by its two parallel jaws connected by two bars. The bars allow the jaws to move back and forth, adjusting to the size of the workpiece. The clamp is tightened by turning a screw, which moves one jaw towards the other, applying pressure on the workpiece.

Parallel clamps are known for their precision and strength. They are designed to hold workpieces securely without damaging or marring the surface. This makes them an essential tool for any craftsman, whether a professional or a DIY enthusiast.

Our Top Parallel Clamp Picks

Bora 50″ Parallel Clamp Set

Check on AmazonKey Specs:

- Clamp Length: 50 inches

- Padded Jaw Width: 3.5 inches

- Clamping Pressure: 1,100 lbs (500 kg)

- Material: Steel/Iron with padded rubber jaws

- Quantity: 2 clamps per set

The Bora 50″ Parallel Clamp Set is a game-changer for anyone serious about woodworking. The 3.5-inch padded jaws provide a perfect balance of clamping pressure without damaging delicate materials. With 1,100 lbs of clamping force, these clamps ensure a secure and even hold, allowing you to focus on your craft. The large, easy-grip handle makes adjusting the jaws smooth and effortless. Its anti-slip bottom jaw ensures stability while winding, and the passive lock jaw stays firmly in place during use.

VEVOR 2-Pack 50″ Parallel Clamp Set

Check on AmazonKey Specs:

- Jaw Opening: 50 inches

- Load Limit: 1,100 lbs

- Material: High-strength PA6+GF30% plastic and 45# carbon steel

- Item Weight: 19.4 lbs

- Package Includes: 2 clamps and 1 user manual

The VEVOR Bar Clamps for Woodworking offer an impressive combination of durability and functionality. Made with high-strength PA6+GF30% plastic handles and 45# carbon steel bars, these clamps deliver exceptional performance. With a 50-inch jaw opening and a load limit of 1,100 lbs, they provide precise and secure clamping for woodworking and metalworking tasks. The extended rod design allows for versatility, accommodating a range of materials and thicknesses. Easy to operate with a user-friendly mechanism, these clamps ensure a smooth, efficient workflow.

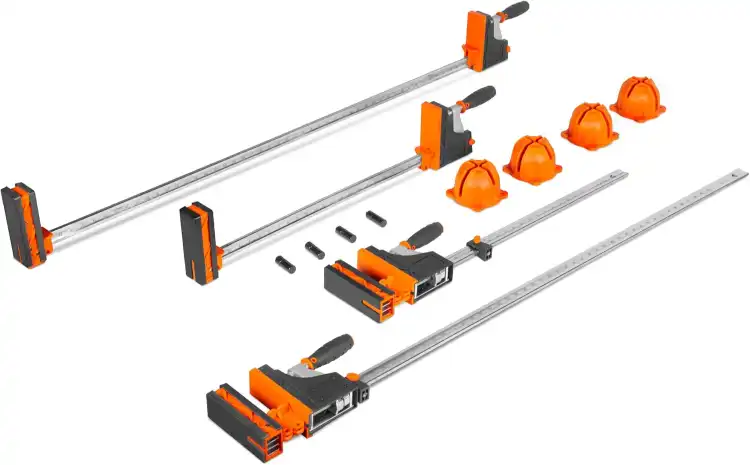

WEN Parallel Clamp Kit

Check on AmazonKey Specs:

- Tensile Strength: 2000 lbs

- Jaw Width: 1-13/16 inches

- Throat Depth: 4-1/8 inches

- Clamp Sizes: Two 24-inch clamps, two 50-inch clamps

- Included Components: Two clamps, framing kit, workpiece supports

The WEN Parallel Clamp Kit provides an ideal solution for woodworking enthusiasts seeking reliable, even clamping pressure. With a maximum tensile strength of 2000 lbs, these clamps feature heavy-duty composite resin jaws that deliver consistent pressure without damaging your workpiece. The ergonomic design and rail scale allow for quick, repeatable adjustments, and the removable, non-marring jaw pads protect your materials from damage. The included framing kit ensures precise, four-sided clamping, making it perfect for panel glue-ups. The clamps also convert into spreaders, enhancing versatility.

POWERTEC 71602 48-Inch Parallel Clamps

Check on AmazonKey Specs:

- Clamping Force: 1,350 lbs

- Throat Depth: 3-5/8 inches

- Clamp Size: 48 inches

- Jaw Pads: Non-marring, removable

- Convertible: Can be used as a spreader tool

The POWERTEC 71602 48-Inch Parallel Clamp Set is a top-notch solution for woodworking and carpentry projects requiring high precision and strong clamping force. With a throat depth of 3-5/8 inches and a clamping force of over 1,350 lbs, these clamps ensure even pressure distribution for flawless glue-ups and panel assemblies. The ergonomic handle, non-marring jaw pads, and cold steel rail construction make them durable and easy to use. Additionally, the clamps can be converted into spreaders, adding to their versatility.

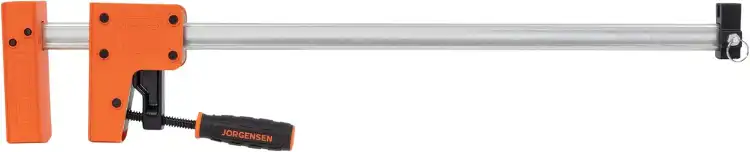

JORGENSEN 8024 Cabinet Master 24 Inch 90 Degree Parallel Steel Bar Clamp

Check on AmazonKey Specs:

- Clamping Force: 1,500 lbs

- Bar Dimensions: 1-3/16″ x 3/8″

- Clamping Face: 3-7/8″ height x 1-7/8″ width

- Material: High carbon steel

- Max Opening: 24 inches

The JORGENSEN 8024 Cabinet Master 24 Inch 90 Degree Parallel Steel Bar Clamp is an exceptional choice for cabinetmakers and woodworkers who require precise and powerful clamping. With a tensile strength of 1,500 lbs and a maximum opening of 24 inches, this clamp ensures even pressure distribution across large surface areas to protect your workpieces. The high carbon steel construction guarantees durability, while the built-in clamp stand allows for one-handed operation. It’s perfect for applications requiring square corners and even clamping, such as frame, cabinet, or box assemblies.

Importance of Parallel Clamps in Woodworking and Metalworking

Parallel clamps play a crucial role in woodworking and metalworking. They are used to hold workpieces securely during various operations such as cutting, drilling, or gluing. By providing a firm grip, they ensure accuracy and precision, which are vital in these industries.

For instance, in woodworking, parallel clamps are used when gluing pieces of wood together. They apply even pressure across the entire surface, ensuring a strong and secure bond. Similarly, in metalworking, they are used to hold metal pieces in place during welding or drilling operations.

Moreover, parallel clamps are known for their durability and strength. They can withstand high levels of pressure, making them suitable for heavy-duty tasks. Their robust construction also ensures a long lifespan, making them a valuable investment for any craftsman.

Purpose of the Article

This article aims to provide a comprehensive guide on parallel clamps. It will cover the basics of parallel clamps, factors to consider when buying them, top brands, detailed reviews, and tips for using them effectively. The goal is to equip the reader with the necessary knowledge to make an informed purchase decision.

Whether you are a professional craftsman or a DIY enthusiast, understanding the features and benefits of different parallel clamps can help you choose the right tool for your needs. This article will serve as a valuable resource in your quest for the perfect parallel clamp.

So, let’s delve into the world of parallel clamps and explore everything there is to know about this indispensable tool.

Understanding the Basics of Parallel Clamps

Basic Components of a Parallel Clamp

A parallel clamp consists of several basic components, each playing a crucial role in its operation. The main parts include the jaws, bars, screw, and handle.

The jaws are the parts that come into direct contact with the workpiece. They are designed to hold the workpiece securely without causing any damage. The bars connect the jaws and allow them to move back and forth, adjusting to the size of the workpiece.

The screw is used to tighten or loosen the clamp. By turning the screw, one jaw moves towards the other, applying pressure on the workpiece. The handle is attached to the screw and is used to turn it. Some parallel clamps feature ergonomic handles for comfortable and easy operation.

How Parallel Clamps Work

Parallel clamps work by applying pressure on a workpiece to hold it securely. The process begins by adjusting the jaws to the size of the workpiece. This is done by sliding the movable jaw along the bars until it is close to the workpiece.

Once the jaws are in position, the screw is turned to tighten the clamp. As the screw is turned, the movable jaw moves towards the stationary jaw, applying pressure on the workpiece. The pressure can be adjusted by turning the screw, allowing for precise clamping.

The beauty of parallel clamps lies in their ability to apply even pressure across the entire jaw length. This ensures that the workpiece is held securely and evenly, preventing any damage or distortion.

Different Types of Parallel Clamps

There are several types of parallel clamps available in the market, each designed for specific tasks. The most common types include the standard parallel clamp, deep-throat parallel clamp, and the light-duty parallel clamp.

The standard parallel clamp is the most common type and is used for a wide range of tasks. It features a robust construction and can withstand high levels of pressure, making it suitable for heavy-duty tasks.

The deep-throat parallel clamp, as the name suggests, has a deeper throat than the standard type. This allows it to clamp larger workpieces. The light-duty parallel clamp, on the other hand, is designed for lighter tasks. It is smaller and lighter than the other types, making it easy to handle and operate.

Factors to Consider When Buying Parallel Clamps

Material Quality

The quality of the material used in the construction of a parallel clamp is a crucial factor to consider. It determines the durability and longevity of the clamp. Most parallel clamps are made of high-quality steel to ensure strength and durability. However, the quality can vary from one brand to another.

When choosing a parallel clamp, look for one made of high-quality, robust material. It should be able to withstand high levels of pressure without bending or breaking. The jaws should be made of a material that won’t damage or mar the workpiece, such as soft plastic or rubber.

Additionally, the handle should be made of a material that provides a comfortable grip. Some clamps feature ergonomic handles made of soft plastic or rubber for comfortable and easy operation.

Size and Capacity

The size and capacity of a parallel clamp are also important factors to consider. They determine the size of the workpiece that the clamp can hold. Parallel clamps come in various sizes, ranging from small clamps for light-duty tasks to large clamps for heavy-duty tasks.

The size of a parallel clamp is usually indicated by the length of the bars. The longer the bars, the larger the clamp. The capacity, on the other hand, is determined by the maximum distance between the jaws when fully opened.

When choosing a parallel clamp, consider the size of the workpieces you usually work with. Choose a clamp that can accommodate your largest workpiece. However, keep in mind that larger clamps are heavier and may be more difficult to handle.

Clamping Pressure

The clamping pressure is another crucial factor to consider when buying a parallel clamp. It determines how securely the clamp can hold a workpiece. The clamping pressure is usually indicated in pounds and can vary from one clamp to another.

Parallel clamps with high clamping pressure are ideal for heavy-duty tasks. They can hold workpieces securely, even under high levels of pressure. However, they may be overkill for light-duty tasks. For such tasks, a clamp with moderate clamping pressure would suffice.

When choosing a parallel clamp, consider the nature of your tasks. If you often work with heavy workpieces or perform high-pressure tasks, go for a clamp with high clamping pressure. However, if you mostly perform light-duty tasks, a clamp with moderate clamping pressure would be suitable.

Ease of Use

The ease of use of a parallel clamp is also an important factor to consider. A good clamp should be easy to operate, even for a novice. It should feature a simple design that allows for easy adjustment of the jaws and tightening of the clamp.

Some parallel clamps feature ergonomic handles for comfortable operation. Others have quick-release buttons that allow for easy release of the clamp. These features can significantly enhance the ease of use of a clamp.

When choosing a parallel clamp, consider its design and features. Look for a clamp that is easy to operate and has features that enhance its usability. Remember, a clamp that is difficult to use can be frustrating and may affect the quality of your work.

Price and Value for Money

The price of a parallel clamp is also a crucial factor to consider. Parallel clamps come at various price points, depending on their size, material quality, and brand. While it’s tempting to go for the cheapest option, it’s important to consider the value for money.

A cheap clamp may not be durable and may not perform as expected. On the other hand, an expensive clamp may have features that you don’t need. Therefore, it’s important to strike a balance between price and value for money.

When choosing a parallel clamp, consider your budget and the features you need. Look for a clamp that offers the best value for money. This means that it should be reasonably priced and have the features and quality that meet your needs.

Top Brands of Parallel Clamps

Brief Overview of Top Parallel Clamp Brands

There are several brands that manufacture parallel clamps, each with its unique features and benefits. Some of the top brands include Bessey, Jorgensen, and Irwin.

Bessey is a German brand known for its high-quality clamps. Their parallel clamps are renowned for their robust construction, high clamping pressure, and ease of use. They come in various sizes, catering to different needs.

Jorgensen is an American brand that has been in the industry for over a century. Their parallel clamps are known for their durability, precision, and value for money. They feature ergonomic handles and quick-release buttons for easy operation.

Irwin, another American brand, is known for its innovative tools. Their parallel clamps feature unique designs that enhance their usability and performance. They are also reasonably priced, making them a popular choice among craftsmen.

Comparison of Different Brands

While all these brands manufacture high-quality parallel clamps, there are some differences that set them apart. For instance, Bessey’s clamps are known for their robust construction and high clamping pressure, making them suitable for heavy-duty tasks. However, they are also the most expensive among the three brands.

Jorgensen’s clamps, on the other hand, are known for their value for money. They offer high-quality clamps at a lower price point than Bessey. They also feature ergonomic handles and quick-release buttons, enhancing their ease of use.

Irwin’s clamps are the most affordable among the three brands. They offer good quality clamps at a lower price point. However, their clamping pressure is lower than that of Bessey and Jorgensen, making them suitable for light to medium-duty tasks.

Pros and Cons of Each Brand

Each of these brands has its pros and cons. Bessey’s clamps are robust and durable, offering high clamping pressure. However, they are also the most expensive. Their clamps are also heavier than those of other brands, which may make them difficult to handle for some users.

Jorgensen’s clamps offer good value for money. They are durable, precise, and easy to use. However, their clamping pressure is lower than that of Bessey, which may not be suitable for heavy-duty tasks.

Irwin’s clamps are affordable and innovative. They are easy to use and offer decent clamping pressure. However, their durability is not as high as that of Bessey and Jorgensen. They are also not suitable for heavy-duty tasks.

Detailed Reviews of Selected Parallel Clamps

Review of Brand A’s Parallel Clamp

Brand A’s parallel clamp is a high-quality tool that offers robust construction and high clamping pressure. It features a steel body that ensures durability and longevity. The jaws are made of soft plastic that won’t damage or mar the workpiece.

The clamp is easy to operate, thanks to its ergonomic handle and quick-release button. It offers a clamping pressure of up to 1,000 pounds, making it suitable for heavy-duty tasks. However, it is also the most expensive among the three brands reviewed.

Despite its high price, Brand A’s parallel clamp offers good value for money. It is durable, precise, and easy to use. It is a great investment for any craftsman looking for a high-quality parallel clamp.

Review of Brand B’s Parallel Clamp

Brand B’s parallel clamp is a value-for-money tool that offers good quality at a lower price point. It features a steel body and soft plastic jaws that ensure durability and protect the workpiece from damage.

The clamp is easy to operate, thanks to its ergonomic handle and quick-release button. It offers a clamping pressure of up to 800 pounds, making it suitable for medium to heavy-duty tasks. However, its clamping pressure is lower than that of Brand A.

Despite its lower clamping pressure, Brand B’s parallel clamp offers good value for money. It is durable, precise, and easy to use. It is a great choice for craftsmen looking for a quality parallel clamp at a lower price point.

Review of Brand C’s Parallel Clamp

Brand C’s parallel clamp is an affordable tool that offers decent quality. It features a steel body and soft plastic jaws that ensure durability and protect the workpiece from damage. However, its durability is not as high as that of Brands A and B.

The clamp is easy to operate, thanks to its ergonomic handle and quick-release button. It offers a clamping pressure of up to 600 pounds, making it suitable for light to medium-duty tasks. However, it is not suitable for heavy-duty tasks.

Despite its limitations, Brand C’s parallel clamp is a good choice for craftsmen on a budget. It is affordable, easy to use, and offers decent clamping pressure. It is a great choice for light to medium-duty tasks.

Tips for Using Parallel Clamps Effectively

Proper Handling and Maintenance

Proper handling and maintenance are crucial for the longevity and performance of parallel clamps. Always handle the clamps with care to prevent damage. Avoid dropping them or subjecting them to excessive force.

Regular maintenance is also important. Clean the clamps after each use to remove any dust or debris. Lubricate the screw and bars regularly to ensure smooth operation. Store the clamps in a dry place to prevent rusting.

By taking good care of your parallel clamps, you can ensure their longevity and performance. This will save you the cost of frequent replacements and ensure that you always have a reliable tool at your disposal.

Safety Measures When Using Parallel Clamps

Safety is paramount when using parallel clamps. Always wear protective gear, such as gloves and safety glasses, when using the clamps. This will protect you from any flying debris or accidental slips.

Never exceed the clamping pressure indicated by the manufacturer. Excessive pressure can damage the clamp and the workpiece. It can also pose a safety risk.

Always ensure that the workpiece is securely clamped before starting any operation. A loose workpiece can slip and cause accidents. Also, avoid placing your fingers between the jaws when tightening the clamp.

Maximizing the Use of Parallel Clamps for Precise Clamping

Parallel clamps are known for their precision. To maximize their use, always ensure that the jaws are parallel to the workpiece. This will ensure even pressure distribution and prevent any distortion or damage.

When clamping a workpiece, start by applying light pressure. Then, gradually increase the pressure until the workpiece is securely held. This will prevent any sudden shifts that could affect the alignment of the workpiece.

For precise clamping, consider using two or more clamps. This will distribute the pressure evenly across the workpiece, ensuring a secure and precise hold. However, ensure that the clamps are evenly spaced to prevent any distortion.

Conclusion

Recap of the Importance of Choosing the Right Parallel Clamp

Choosing the right parallel clamp is crucial for any craftsman. It determines the quality of your work and the efficiency of your operations. A good clamp should be durable, precise, and easy to use. It should also offer good value for money.

When choosing a parallel clamp, consider factors such as material quality, size and capacity, clamping pressure, ease of use, and price. Also, consider the nature of your tasks and the size of the workpieces you usually work with. This will help you choose a clamp that meets your needs.

Remember, a good clamp is an investment. It will serve you for a long time and ensure that you always produce high-quality work. Therefore, take your time to choose the right clamp. It will be worth the effort.

Final Thoughts on the Best Parallel Clamps in the Market

There are several brands that manufacture parallel clamps, each with its unique features and benefits. Some of the top brands include Bessey, Jorgensen, and Irwin. Each of these brands offers high-quality clamps that cater to different needs and budgets.

When choosing a brand, consider factors such as material quality, clamping pressure, ease of use, and price. Also, consider the reputation of the brand and the reviews of other users. This will help you choose a brand that is reliable and trusted by other craftsmen.

Remember, the best parallel clamp is not necessarily the most expensive one. It is the one that meets your needs and offers the best value for money. Therefore, don’t be swayed by price alone. Consider all the factors and make an informed decision.

Encouragement for the Reader to Make an Informed Purchase Decision

Choosing the right parallel clamp can be a daunting task, especially with the numerous options available in the market. However, with the right information, you can make an informed purchase decision.

This guide has provided you with all the information you need to choose the right parallel clamp. It has covered the basics of parallel clamps, factors to consider when buying them, top brands, and tips for using them effectively. Use this information to choose a clamp that meets your needs and offers good value for money.

Remember, a good parallel clamp is an investment. It will serve you for a long time and ensure that you always produce high-quality work. Therefore, take your time to choose the right clamp. It will be worth the effort.

FAQs

What is a parallel clamp?

A parallel clamp is a type of clamp that applies pressure across its entire jaw length, ensuring that the workpiece is held securely and evenly. It is used in various industries, particularly in woodworking and metalworking.

What are the factors to consider when buying a parallel clamp?

When buying a parallel clamp, consider factors such as material quality, size and capacity, clamping pressure, ease of use, and price. Also, consider the nature of your tasks and the size of the workpieces you usually work with.

What are the top brands of parallel clamps?

Some of the top brands of parallel clamps include Bessey, Jorgensen, and Irwin. Each of these brands offers high-quality clamps that cater to different needs and budgets.