Definition of a Manometer

A manometer is a device that measures pressure. The term originates from the Greek word ‘manos’ meaning ‘thin’ or ‘rare’, and ‘metron’ meaning ‘measure’. It is an instrument that uses a column of liquid to measure and indicate pressure. The liquid can be water, mercury, or any other fluid depending on the specific application and the range of pressure to be measured.

Manometers are typically used in a variety of fields such as physics, engineering, and medicine. They are used to measure the pressure of gas or liquid, differential pressure (the difference in pressure between two points), and atmospheric pressure.

Manometers are known for their accuracy and simplicity. They are often used in laboratory settings because they are relatively easy to use and can provide very precise measurements.

Our Top Manometer Picks

Hti Xintai Digital Manometer

Check on AmazonKey Specs

- Pressure Range: ±2 psi

- Resolution: 0.001 psi

- Selectable Units: 11 options

- Port Size: 5/16″ pressure port

- Dimensions: 5.79 x 2.16 x 1.26 inches

The Hti Xintai Digital Manometer is an indispensable tool for precise gas pressure measurement. Its 5/16″ pressure port and flexible silicone tubing ensure seamless compatibility with most gas valves, saving you from purchasing extra accessories. I particularly appreciate the 11 selectable units and high resolution (0.001 psi), making it incredibly accurate. The Min/Max/Avg recording mode and HOLD function allow for convenient data logging. The slim design is perfect for one-handed operation, ideal for field use.

RisePro Manometer

Check on AmazonKey Specs:

- Pressure Range: ±2.000 psi

- Resolution: 0.001 psi

- Accuracy: ±0.3% full scale

- Max Pressure: 10 psi (readings above 2 psi may not show)

- Selectable Units: 11 units (InH2O, Psi, Mbar, kPa, and more)

The RisePro Manometer is a highly versatile tool, offering precise differential pressure measurements with its dual input probes. Its ability to measure up to ±2.000 psi with a 0.001 psi resolution and an accuracy of ±0.3% makes it an excellent choice for professionals. I particularly value its 11 selectable measurement units, providing flexibility for different applications. The backlit display, data hold, and auto off features are great for ensuring ease of use in various work environments.

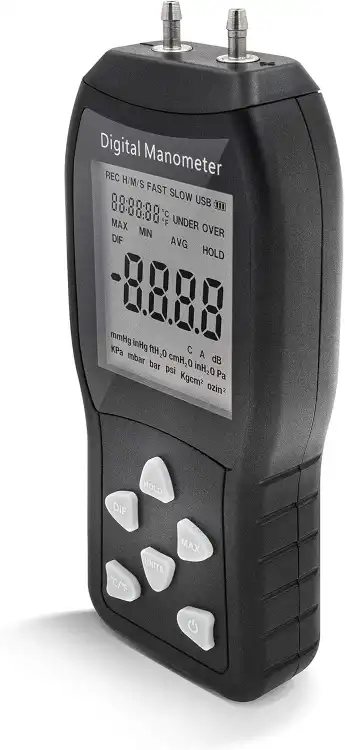

Tekcoplus Digital Handheld Manometer

Check on AmazonKey Specs:

- Selectable Units: 12 units (Psi, kg-cm², Ozin², kPa, inHg, etc.)

- Accuracy: ±0.3% FSO

- Resolution: 0.001 psi

- Data Storage: Records up to 100 sets of measurements

- Display: Large LCD with backlight for easy reading

The Tekcoplus Digital Handheld Manometer stands out for its 12 selectable units of measurement, offering unparalleled flexibility for various applications. With an accuracy of 0.3% FSO and 0.001 psi resolution, it ensures precise readings. The dual ports enable positive and negative pressure measurements, while its Min/Max feature makes it easy to track pressure changes. The large backlit display enhances readability, especially in low-light conditions, and the rechargeable battery adds convenience for long-term use.

UEi Test Instruments EM201B Test Dual Input Differential Manometer

Check on AmazonKey Specs:

- Measurement Range: Up to 40 inches of water gauge

- Resolution: 0.001wg (below 9.999 inches)

- Scales: Pascal, Wag, mbar, PSI

- Features: Min/Max recording, Data hold, Auto power-off

- Display: Back-lit for easy reading in low-light conditions

The UEi Test Instruments EM201B Dual Input Differential Manometer is engineered for precision and durability. It features a dual input design, measuring up to 40 inches of water gauge, with 0.001wg resolution below 9.999 inches. The manometer includes a range of scales, including Pascal’s, Wag, mbar, and PSI, making it versatile for various applications. Its dynamic Min/Max feature, data hold, and auto power-off function provide added convenience, while the back-lit display ensures visibility in any lighting.

PerfectPrime AR1890 Professional Digital Air Pressure Meter

Check on AmazonKey Specs:

- Measuring Range: ±13.79 kPa / ±2 psi / ±55.4 H2O

- Accuracy: ±0.3% in full scale

- Selectable Scales: 11 units including inH2O, psi, bar, mbar, kPa, etc.

- Features: Zero adjust, Data hold, MAX/MIN values with time stamps

- Display: Large LCD with backlight for visibility in low-light conditions

The PerfectPrime AR1890 Professional Digital Air Pressure Meter offers advanced measurement capabilities with a large LCD backlit display for easy reading. It provides high accuracy with a measuring range of ±13.79 kPa, ±2 psi, and ±55.4 H2O, with an impressive ±0.3% accuracy. The device supports 11 selectable scales and units such as inH2O, psi, bar, mbar, and more. Additionally, features like zero adjust, data hold, and MAX/MIN values with time stamps enhance its usability, while the auto power-off ensures energy efficiency.

Importance of Accurate Pressure Measurement

Accurate pressure measurement is vital in many industries and fields of study. In the medical field, for example, accurate pressure measurement can be the difference between life and death. Blood pressure readings, for instance, need to be precise to ensure proper diagnosis and treatment.

In the field of engineering, accurate pressure measurements are crucial in the design and operation of various systems and machinery. For instance, in the operation of a steam boiler, accurate pressure measurements are necessary to ensure the safety and efficiency of the system.

Furthermore, in the field of research and development, accurate pressure measurements are essential in conducting experiments and testing theories. Without accurate measurements, the results of an experiment could be skewed, leading to incorrect conclusions.

Understanding the Basics of Pressure Measurement

Concept of Pressure Measurement

Pressure is defined as the force applied per unit area. It is usually measured in units of force per square inch (psi), or in metric units, such as pascals (Pa) or bars. The pressure of a gas or liquid can be measured in terms of the force it exerts on the walls of its container.

Pressure measurement is a fundamental parameter in fluid mechanics, which is the study of fluids (liquids, gases, and plasmas) and the forces on them. It is also a key parameter in thermodynamics, the study of heat and temperature and their relation to energy and work.

The measurement of pressure is often carried out using a device known as a pressure gauge or manometer. These devices measure the pressure relative to atmospheric pressure (also known as gauge pressure) or relative to a perfect vacuum (also known as absolute pressure).

Role of Manometers in Pressure Measurement

Manometers play a crucial role in pressure measurement. They are used to measure low pressures, such as those found in vacuum systems, and also high pressures, such as those found in hydraulic systems. Manometers provide a simple and direct method to measure pressure.

Manometers work on the principle of balancing the weight of a fluid column against the pressure to be measured. In a simple manometer, one end of a tube is open to the atmosphere or to the pressure to be measured, and the other end is connected to the system whose pressure is to be measured. The height of the fluid column in the tube then gives a direct measure of the pressure.

Manometers are known for their high accuracy and are often used as a standard to calibrate other pressure measuring devices. They are also used in a wide range of applications, from laboratory experiments to industrial processes.

Types of Manometers

Brief Overview of Different Types

There are several types of manometers, each with its own specific uses and advantages. The most common types are the U-tube manometer, the well-type manometer, the inclined manometer, and the digital manometer.

The U-tube manometer is the simplest type and is often used in laboratories for its simplicity and accuracy. The well-type manometer is a variation of the U-tube manometer that is designed to measure larger pressures. The inclined manometer is another variation that is designed to measure very small pressures with high accuracy.

The digital manometer, on the other hand, is a modern type of manometer that uses electronic sensors to measure pressure. It provides a digital readout and is often used in industrial applications for its convenience and ease of use.

Detailed Description of Each Type

U-Tube Manometer

The U-tube manometer is the simplest and most commonly used type of manometer. It consists of a U-shaped tube filled with a liquid, usually mercury or water. One end of the tube is open to the atmosphere, and the other end is connected to the system whose pressure is to be measured.

The pressure is determined by measuring the difference in height between the two columns of liquid in the U-tube. The pressure is directly proportional to the difference in height, so the greater the difference, the higher the pressure.

U-tube manometers are known for their simplicity and accuracy. They are often used in laboratories and educational settings for teaching and demonstration purposes.

Well-Type Manometer

The well-type manometer is a variation of the U-tube manometer that is designed to measure larger pressures. It consists of a U-shaped tube with one end enlarged to form a well. The well serves as a reservoir for the liquid, allowing the manometer to measure larger pressures without requiring a long tube.

The pressure is determined by measuring the difference in height between the liquid level in the well and the liquid level in the tube. The pressure is directly proportional to the difference in height, so the greater the difference, the higher the pressure.

Well-type manometers are often used in industrial applications where large pressures need to be measured.

Inclined Manometer

The inclined manometer is another variation of the U-tube manometer that is designed to measure very small pressures with high accuracy. It consists of a U-shaped tube with one arm inclined at an angle. The inclined arm allows the manometer to measure small changes in pressure with a high degree of accuracy.

The pressure is determined by measuring the difference in height along the inclined arm. The pressure is directly proportional to the difference in height, so the smaller the difference, the lower the pressure.

Inclined manometers are often used in laboratory settings where high accuracy is required.

Digital Manometer

The digital manometer is a modern type of manometer that uses electronic sensors to measure pressure. It provides a digital readout, making it easy to read and interpret the results.

Digital manometers use a variety of sensing technologies, including piezoresistive, capacitive, and optical sensors. These sensors convert the pressure into an electrical signal, which is then processed and displayed as a digital reading.

Digital manometers are often used in industrial applications for their convenience and ease of use. They are also used in applications where a quick and easy readout is required, such as in field service and maintenance work.

Factors to Consider When Buying a Manometer

Accuracy

Accuracy is one of the most important factors to consider when buying a manometer. The accuracy of a manometer is usually expressed as a percentage of its full scale reading. For example, a manometer with an accuracy of ±1% of full scale can measure pressure with an error of up to 1% of its maximum pressure rating.

The accuracy of a manometer depends on several factors, including the quality of its construction, the precision of its scale, and the stability of its readings. High-quality manometers are usually made with precision-machined parts and high-quality materials to ensure accurate and stable readings.

It’s important to choose a manometer with an accuracy that is suitable for your specific application. For example, if you need to measure pressure with a high degree of precision, you should choose a manometer with a high accuracy rating.

Range of Measurement

The range of measurement is another important factor to consider when buying a manometer. The range of measurement refers to the minimum and maximum pressures that a manometer can measure.

Manometers are available in a wide range of pressure ratings, from low-pressure models that can measure pressures of a few millibars, to high-pressure models that can measure pressures of several thousand psi.

It’s important to choose a manometer with a range of measurement that is suitable for your specific application. For example, if you need to measure very low pressures, you should choose a manometer with a low-pressure rating. On the other hand, if you need to measure high pressures, you should choose a manometer with a high-pressure rating.

Durability and Quality

Durability and quality are also important factors to consider when buying a manometer. A durable and high-quality manometer will provide accurate and reliable readings over a long period of time.

High-quality manometers are usually made with durable materials, such as stainless steel or brass, and are designed to withstand harsh conditions, such as high temperatures, high pressures, and corrosive environments.

It’s also important to consider the quality of the manometer’s construction. High-quality manometers are usually precision-machined and assembled with care to ensure accurate and reliable readings.

Ease of Use

Ease of use is another important factor to consider when buying a manometer. A manometer that is easy to use will make your job easier and more efficient.

Some features that can make a manometer easier to use include a clear and easy-to-read scale, a simple and intuitive interface, and a convenient and ergonomic design.

Digital manometers, in particular, are known for their ease of use. They provide a digital readout that is easy to read and interpret, and they often come with features such as backlighting, data logging, and wireless connectivity, which can make your job even easier.

Price

Price is also an important factor to consider when buying a manometer. The price of a manometer can vary widely, depending on its type, its features, and its quality.

While it’s important to choose a manometer that fits within your budget, it’s also important to consider the value that the manometer provides. A high-quality manometer may cost more upfront, but it can provide accurate and reliable readings over a long period of time, making it a good investment in the long run.

It’s also worth considering the cost of ownership, which includes the cost of maintenance and calibration. Some manometers require regular calibration to maintain their accuracy, which can add to their cost of ownership.

Understanding Manometer Specifications

Reading and Interpreting Specifications

When buying a manometer, it’s important to understand its specifications. The specifications provide detailed information about the manometer’s performance and capabilities, and can help you choose a manometer that is suitable for your specific application.

Some of the key specifications to look for include the range of measurement, the accuracy, the resolution, the response time, and the operating temperature range.

The range of measurement indicates the minimum and maximum pressures that the manometer can measure. The accuracy indicates the maximum error that can be expected in the manometer’s readings. The resolution indicates the smallest change in pressure that the manometer can detect. The response time indicates how quickly the manometer can respond to changes in pressure. The operating temperature range indicates the range of temperatures at which the manometer can operate.

Importance of Specifications in Choosing the Right Manometer

The specifications of a manometer are important in choosing the right manometer for your specific application. By understanding the specifications, you can ensure that the manometer has the capabilities that you need.

For example, if you need to measure very low pressures, you should choose a manometer with a low-pressure rating. If you need to measure pressure with a high degree of precision, you should choose a manometer with a high accuracy rating. If you need to measure pressure in a harsh environment, you should choose a manometer with a high operating temperature range.

By understanding the specifications, you can also compare different manometers and choose the one that offers the best value for your needs. For example, you can compare the accuracy, the range of measurement, and the price of different manometers to find the one that offers the best combination of performance and value.

Top Manometer Brands

Brief Overview of Top Brands

There are several top brands that manufacture high-quality manometers. These include Fluke, Dwyer, Extech, and Testo.

Fluke is a well-known brand that manufactures a wide range of test and measurement equipment, including digital manometers. Fluke manometers are known for their high quality, accuracy, and durability.

Dwyer is another well-known brand that specializes in the manufacture of manometers. Dwyer offers a wide range of manometers, including U-tube manometers, well-type manometers, and inclined manometers. Dwyer manometers are known for their high accuracy and reliability.

Extech is a brand that offers a range of test and measurement equipment, including digital manometers. Extech manometers are known for their ease of use and value for money.

Testo is a brand that specializes in the manufacture of measurement instruments, including digital manometers. Testo manometers are known for their high quality, accuracy, and innovative features.

Comparison of Brands Based on User Reviews and Expert Opinions

Based on user reviews and expert opinions, Fluke, Dwyer, Extech, and Testo are all highly rated brands that manufacture high-quality manometers.

Fluke manometers are often praised for their high quality, accuracy, and durability. Users appreciate the rugged design of Fluke manometers, which can withstand harsh conditions and provide accurate and reliable readings over a long period of time.

Dwyer manometers are often praised for their high accuracy and reliability. Users appreciate the precision of Dwyer manometers, which can provide accurate and stable readings. Dwyer also offers a wide range of manometers, allowing users to choose the one that is most suitable for their specific application.

Extech manometers are often praised for their ease of use and value for money. Users appreciate the intuitive interface and convenient features of Extech manometers, which make them easy to use. Extech manometers are also competitively priced, making them a good choice for users on a budget.

Testo manometers are often praised for their high quality, accuracy, and innovative features. Users appreciate the advanced features of Testo manometers, such as wireless connectivity and data logging, which can make their job easier and more efficient.

Proper Use and Maintenance of Manometers

Guidelines for Using Manometers

When using a manometer, it’s important to follow the manufacturer’s guidelines to ensure accurate and safe operation. Here are some general guidelines for using manometers:

First, before using the manometer, check that it is in good condition and that there are no visible signs of damage. If the manometer is damaged, do not use it as it may not provide accurate readings.

Second, when connecting the manometer to the system whose pressure is to be measured, make sure that the connection is secure and that there are no leaks. A leak can cause the manometer to provide inaccurate readings.

Third, when reading the manometer, make sure to read it at eye level and perpendicular to the scale. Reading the manometer from an angle can cause a parallax error, which can lead to inaccurate readings.

Finally, after using the manometer, clean it and store it in a safe place. Avoid exposing the manometer to extreme temperatures or humidity, as this can damage the manometer and affect its accuracy.

Tips for Maintaining and Extending the Life of Manometers

Proper maintenance is key to extending the life of a manometer and ensuring its continued accuracy and reliability. Here are some tips for maintaining and extending the life of manometers:

First, clean the manometer regularly to remove dust and dirt. Dust and dirt can clog the manometer and affect its accuracy. Use a soft cloth to clean the manometer, and avoid using harsh or abrasive cleaners that can damage the manometer.

Second, calibrate the manometer regularly to ensure its accuracy. Over time, the accuracy of the manometer can drift due to wear and tear, changes in temperature, and other factors. Regular calibration can correct this drift and ensure that the manometer continues to provide accurate readings.

Third, store the manometer in a safe and dry place when not in use. Avoid exposing the manometer to extreme temperatures or humidity, as this can damage the manometer and affect its accuracy. Also, avoid dropping or knocking the manometer, as this can damage the manometer and affect its accuracy.

Finally, if the manometer is damaged or not working properly, have it repaired or replaced by a qualified technician. Attempting to repair the manometer yourself can cause further damage and affect its accuracy.

Potential Issues and Troubleshooting

Common Problems with Manometers

Despite their simplicity and reliability, manometers can sometimes encounter problems that can affect their accuracy and performance. Here are some common problems with manometers:

First, the manometer may provide inaccurate readings. This can be caused by a variety of factors, including leaks, clogs, temperature changes, and calibration errors. If the manometer is providing inaccurate readings, check for leaks and clogs, adjust for temperature changes, and calibrate the manometer.

Second, the manometer may not respond to changes in pressure. This can be caused by a clog in the manometer or a problem with the pressure source. If the manometer is not responding to changes in pressure, check for clogs and ensure that the pressure source is functioning properly.

Finally, the manometer may be damaged or not working properly. This can be caused by physical damage, such as a cracked tube or a broken scale, or by a malfunction in the manometer’s components. If the manometer is damaged or not working properly, have it repaired or replaced by a qualified technician.

Basic Troubleshooting Steps

If you encounter problems with your manometer, here are some basic troubleshooting steps that you can take:

First, check for visible signs of damage. If the manometer is cracked, broken, or otherwise damaged, have it repaired or replaced by a qualified technician.

Second, check for leaks. If there is a leak in the manometer or in the connection to the pressure source, the manometer may provide inaccurate readings. Fix any leaks before using the manometer.

Third, check for clogs. If the manometer is clogged with dust or dirt, it may not respond to changes in pressure. Clean the manometer to remove any clogs.

Finally, calibrate the manometer. If the manometer is providing inaccurate readings, it may need to be calibrated. Follow the manufacturer’s instructions to calibrate the manometer, or have it calibrated by a qualified technician.

Conclusion

Recap of Manometer Buying Guide

In conclusion, a manometer is a valuable tool for measuring pressure in a variety of fields and applications. When buying a manometer, it’s important to consider factors such as accuracy, range of measurement, durability and quality, ease of use, and price.

Understanding the specifications of a manometer can help you choose the right manometer for your specific application. Top brands such as Fluke, Dwyer, Extech, and Testo offer high-quality manometers that are highly rated by users and experts.

Proper use and maintenance can extend the life of a manometer and ensure its continued accuracy and reliability. If you encounter problems with your manometer, basic troubleshooting steps can help you resolve the issues.

FAQ

What is a manometer?

A manometer is a device used to measure the pressure of gases or liquids within a system, often used in various industries like HVAC or plumbing.

How does a manometer work?

It works by comparing the pressure of a substance to a known reference, such as atmospheric pressure, and displays the measurement on a scale.

What types of pressure can a manometer measure?

Manometers can measure both positive and negative pressure, as well as vacuum pressure in some models.

Where is a manometer typically used?

It’s commonly used in applications like checking gas lines, measuring water pressure, and monitoring air pressure in systems such as HVAC or pipelines.

Are there different types of manometers?

Yes, there are several types, including U-tube, digital, and dial manometers, each suited for specific applications and accuracy needs.