Lathe mill combos are the ultimate all-in-one tools for any workshop, combining the precision of a lathe with the versatility of a milling machine. These hybrid machines allow you to perform both turning and milling operations on a single piece of equipment, saving valuable space and improving efficiency. Whether you’re working on metal, wood, or plastics, lathe mill combos are perfect for intricate parts, custom projects, and even prototyping.

Designed for both hobbyists and professionals, these machines offer the flexibility to switch between functions seamlessly, ensuring precise results every time. With adjustable settings, powerful motors, and user-friendly controls, lathe mill combos provide maximum control over your projects.

If you’re looking to maximize your workshop’s capability without taking up extra space, a lathe mill combo is the perfect tool to bring versatility and precision to your craft.

Our Top Lathe Mill Picks

Shop Fox M1018 Combo Lathe/Mill

Check on AmazonKey Specs

- Voltage: 110 Volts

- Maximum Speed: 1300 RPM

- Drilling Capacity: 7/8-inch steel

- Spindle Bore: 3/4-inch

- Included Components: 4-way turret tool post, 3-jaw chuck, rotating vise, change gears, and more.

The Shop Fox M1018 Combo Lathe/Mill is a powerful, versatile machine designed for precision metalworking. With a 3/4-inch spindle bore and a maximum rotational speed of 1300 RPM, it offers exceptional flexibility for various tasks. The unit includes a 4-way turret tool post, 3-jaw chuck, rotating vise, and change gears, making it ideal for drilling, turning, and milling. Its sturdy build and variable spindle speeds provide reliable results, while its 110-volt, 4.3-amp motor ensures strong performance.

Proxxon 34104 Mill/ Drill Head PF 230

Check on AmazonKey Specs:

- Maximum Speed: 2200 RPM

- Voltage: 120 Volts

- Amperage: 6 Amps

- Chuck Size: Maximum 0.39 inches

- Included Collets: 15/64″, 5/16″, 25/64″ (6mm, 8mm, 10mm)

The Proxxon 34104 Mill/Drill Head PF 230 is designed for precision machining with Proxxon’s renowned engineering. This high-performance mill/drill head offers five selectable speeds from 280 to 2200 RPM, making it ideal for a variety of tasks. It operates at 120 Volts with a 6-amp motor and includes three collets (sizes 15/64″ – 5/16″ and 25/64″) for versatile use. With a maximum chuck size of 0.39 inches, this tool provides excellent control and accuracy.

Hengwei Desktop Mini Lathe

Check on Amazon

Key Specs:

- Maximum Workpiece Turning Diameter: 125mm

- Maximum Length of Piece: 180mm

- Maximum Turning Diameter on Tool Holder: 60mm

- Spindle Through Hole Diameter: 9mm

- Spindle Cone: MT.1

The Hengwei Desktop Mini Lathe is a compact and versatile tool designed for small-scale machining projects. It features a maximum workpiece turning diameter of 125mm and a maximum piece length of 180mm, making it ideal for precision work on smaller items. The spindle through hole diameter is 9mm, with a spindle cone of MT.1, allowing for various tool and attachment options. With a maximum turning diameter of 60mm on the tool holder, this lathe is perfect for hobbyists and small workshop tasks.

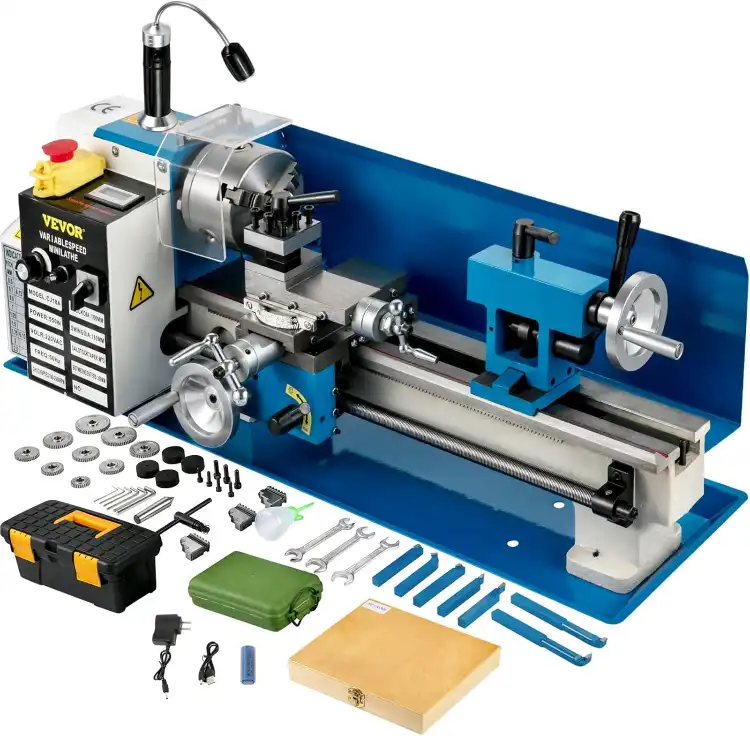

VEVOR Mini Metal Lathe

Check on AmazonKey Specs:

- Chuck Size: 4-inch 3-jaw

- Swing Over Bed: 7.09″/180mm

- Center Distance: 13.78″/350mm

- Speed Range: 50 to 2500 rpm

- Motor Power: 550W

The VEVOR Mini Metal Lathe is a high-precision tool designed for both square and round objects. Featuring a 4-inch 3-jaw chuck, it’s perfect for accurate tasks like threading. Powered by a 550W motor, it handles small to medium projects with a 7.09″/180mm swing over the bed and 13.78″/350mm center distance. Its durable metal gears, aluminum handwheel, digital speed control, and LED lamp make it a versatile and reliable option for professionals, ensuring consistent performance even in low-light environments.

Grizzly Industrial G9729-31″ 3/4 HP Combo Lathe/Mill

Check on AmazonKey Specs:

- Horsepower: 1 HP

- Power Source: Corded Electric

- Base Type: Fixed

- Milling Table: Built-in with T-slots

- Feeds: Power longitudinal and cross feed

The Grizzly Industrial G9729 31″ Combo Lathe/Mill is a versatile machine designed for precision in both lathe and milling operations. Powered by two separate motors, it features a built-in milling table with T-slots and a forward/reverse switch for convenience. The lathe includes power longitudinal and cross feeds for smooth and controlled movements, making it ideal for both professional and hobbyist machinists who require durability and high-performance for their metalworking projects.

Understanding the Functionality of Lathe Mill Combos

Lathe mill combos are multifunctional machines that can perform a variety of tasks. The lathe function allows the machine to rotate a workpiece on its axis to perform operations such as cutting, sanding, knurling, drilling, or deformation. This is particularly useful for creating symmetrical objects like cylinders or spheres.

The milling function, on the other hand, uses rotary cutters to remove material from a workpiece. This can be done along different axes to create a variety of shapes and sizes. Milling is commonly used for tasks such as drilling, slot cutting, and threading.

By combining these two functions into one machine, a lathe mill combo offers a high level of versatility. It allows the user to switch between different operations without having to change machines, saving time and increasing efficiency. Whether you need to turn a piece of metal into a cylindrical shape or drill precise holes into a workpiece, a lathe mill combo can get the job done.

The Importance of Lathe Mill Combos in Various Industries

Lathe mill combos play a crucial role in various industries due to their versatility and efficiency. In the manufacturing industry, these machines are used to produce parts and components for a wide range of products. They are also commonly used in the automotive industry for tasks such as turning brake drums and rotors, or milling keyways and slots.

In the construction industry, lathe mill combos are used to create structural components, while in the aerospace industry, they are used to manufacture parts for aircraft and spacecraft. These machines are also popular in the metalworking industry, where they are used for tasks such as cutting, shaping, and drilling metal.

Even in industries where the use of lathe mill combos is not as prevalent, these machines can still offer significant benefits. For example, in the woodworking industry, a lathe mill combo can be used to create intricate designs and patterns on wood. Regardless of the industry, a lathe mill combo can be a valuable tool for any workshop.

Factors to Consider Before Buying a Lathe Mill Combo

Before purchasing a lathe mill combo, it’s important to consider several factors to ensure you choose the right machine for your needs. One of the most important factors is the size of the machine. You need to ensure that the machine will fit in your workshop and that it has enough capacity to handle the tasks you plan to use it for.

Another important factor to consider is the power of the machine. The power of a lathe mill combo is usually measured in horsepower (HP). The higher the horsepower, the more powerful the machine. A more powerful machine will be able to handle heavier workloads and perform tasks more quickly.

Finally, you should also consider the features of the machine. Some lathe mill combos come with additional features such as digital readouts, variable speed controls, and automatic tool changers. While these features can increase the price of the machine, they can also make it more convenient and efficient to use.

Understanding the Different Types of Lathe Mill Combos

There are several types of lathe mill combos available on the market, each with its own set of features and capabilities. One of the most common types is the benchtop lathe mill combo. These machines are compact and lightweight, making them ideal for small workshops or home use. Despite their small size, benchtop lathe mill combos are capable of performing a wide range of tasks.

Another common type of lathe mill combo is the floor-standing model. These machines are larger and more powerful than benchtop models, making them suitable for heavy-duty tasks. Floor-standing lathe mill combos often come with additional features such as larger work capacities, more powerful motors, and more advanced controls.

Finally, there are also CNC lathe mill combos. These machines use computer numerical control (CNC) to automate the machining process. CNC lathe mill combos are capable of performing complex operations with a high level of precision and accuracy. However, they are also more expensive than other types of lathe mill combos.

The Role of Size and Weight in Choosing a Lathe Mill Combo

The size and weight of a lathe mill combo play a crucial role in determining its suitability for your needs. The size of the machine will determine the space it requires in your workshop and the size of the workpieces it can handle. If you plan to work on large projects, you will need a machine with a large work capacity. However, if your workshop is small, you may need to opt for a compact machine.

The weight of the machine is also an important consideration. A heavy machine will be more stable and less likely to vibrate during operation, resulting in more accurate and precise results. However, a heavy machine will also be more difficult to move and may require a dedicated space in your workshop.

When choosing a lathe mill combo, it’s important to strike a balance between size and weight. You need a machine that is large enough to handle your projects, but not so large that it takes up too much space in your workshop. Similarly, you need a machine that is heavy enough to provide stability, but not so heavy that it’s difficult to move or install.

The Significance of Power and Speed in Lathe Mill Combos

The power and speed of a lathe mill combo are crucial factors that determine its performance and capabilities. The power of the machine, usually measured in horsepower (HP), determines the amount of force the machine can exert on the workpiece. A more powerful machine can handle heavier workloads and perform tasks more quickly.

The speed of the machine, on the other hand, determines how fast the machine can rotate the workpiece or the cutting tool. A machine with a high speed can perform tasks more quickly, but it may also generate more heat and wear out the cutting tool more quickly. Therefore, it’s important to choose a machine with a speed that is suitable for the tasks you plan to use it for.

Many lathe mill combos come with variable speed controls, allowing you to adjust the speed of the machine to suit different tasks. This can be particularly useful when working on delicate or intricate projects that require a high level of precision and control.

The Importance of Material Quality in Lathe Mill Combos

The quality of the materials used in a lathe mill combo is a crucial factor that determines its durability and performance. A machine made from high-quality materials will be more durable and capable of withstanding heavy workloads without breaking down. This is particularly important for professional machinists who use their machines on a regular basis.

One of the most important components of a lathe mill combo is the bed, which supports the workpiece and the cutting tool. The bed should be made from a durable material such as cast iron or steel to ensure it can withstand the forces exerted during operation. The quality of the bed can have a significant impact on the accuracy and precision of the machine.

Other important components include the spindle, which holds the cutting tool, and the tailstock, which supports the other end of the workpiece. These components should also be made from high-quality materials to ensure they can withstand the forces exerted during operation. A machine with high-quality components will not only last longer, but it will also perform better.

Evaluating the Durability and Longevity of Lathe Mill Combos

The durability and longevity of a lathe mill combo are crucial factors to consider when making a purchase. A durable machine will be able to withstand heavy workloads and frequent use without breaking down. This is particularly important for professional machinists who rely on their machines to make a living.

The longevity of a machine, on the other hand, refers to how long it can continue to perform at a high level before it needs to be replaced. A machine with a long lifespan will provide better value for money in the long run, as it will not need to be replaced as frequently.

When evaluating the durability and longevity of a lathe mill combo, it’s important to consider the quality of the materials used in its construction, the design of the machine, and the reputation of the manufacturer. A machine made from high-quality materials, with a robust design, and manufactured by a reputable company is likely to be more durable and long-lasting.

The Role of Precision and Accuracy in Lathe Mill Combos

Precision and accuracy are crucial factors in any machining process. The precision of a lathe mill combo refers to its ability to perform tasks consistently and reliably, while the accuracy refers to its ability to produce results that are close to the intended measurements.

A machine with a high level of precision and accuracy will be able to produce high-quality results consistently. This is particularly important for tasks that require a high level of detail or for producing parts that need to fit together precisely.

Many factors can affect the precision and accuracy of a lathe mill combo, including the quality of the components, the design of the machine, and the skill of the operator. Therefore, when choosing a lathe mill combo, it’s important to consider not only the specifications of the machine, but also your own skill level and the tasks you plan to use it for.

Understanding the Safety Features of Lathe Mill Combos

Safety is a crucial consideration when using any type of machinery, and lathe mill combos are no exception. These machines come with a variety of safety features designed to protect the operator and prevent accidents.

One common safety feature is the emergency stop button, which allows the operator to immediately stop the machine in case of an emergency. Other safety features may include safety guards to protect the operator from flying debris, interlocks to prevent the machine from operating when the guard is open, and overload protection to prevent the machine from being damaged by excessive loads.

When choosing a lathe mill combo, it’s important to consider the safety features it comes with. However, it’s also important to remember that no machine is completely safe without proper operation. Therefore, it’s crucial to read and understand the operator’s manual, use the machine as instructed, and always wear appropriate safety gear.

The Impact of Price and Budget on Your Lathe Mill Combo Purchase

The price of a lathe mill combo can vary significantly depending on its features, size, and brand. Therefore, it’s important to consider your budget before making a purchase. While it may be tempting to opt for the cheapest option, it’s important to remember that you often get what you pay for. A cheap machine may not be as durable or reliable as a more expensive one, and it may not come with the features you need.

On the other hand, it’s also important not to overspend on a machine that has features you don’t need. Before making a purchase, it’s a good idea to make a list of the tasks you plan to use the machine for and the features you need. This will help you choose a machine that fits your needs and your budget.

Finally, it’s also worth considering the cost of ownership. This includes the cost of maintenance, repairs, and replacement parts. A machine with a low purchase price may end up costing more in the long run if it requires frequent maintenance or expensive replacement parts.

The Role of Brand Reputation in Choosing a Lathe Mill Combo

The reputation of the brand is another important factor to consider when choosing a lathe mill combo. A reputable brand is likely to produce high-quality machines that are durable, reliable, and come with good customer service.

One way to assess the reputation of a brand is to read customer reviews and ratings. These can provide valuable insights into the quality of the machine and the customer service provided by the brand. However, it’s important to take these reviews with a grain of salt, as they may not always be representative of the average customer experience.

Another way to assess the reputation of a brand is to look at its history and track record. A brand that has been around for a long time and has a history of producing high-quality machines is likely to be a safe bet. However, this doesn’t mean that newer brands should be ruled out. Some new brands may offer innovative features or better value for money.

The Importance of Customer Reviews and Ratings in Making a Decision

Customer reviews and ratings can provide valuable insights into the performance and reliability of a lathe mill combo. They can reveal potential issues or drawbacks that may not be apparent from the product description or specifications.

When reading customer reviews, it’s important to look for common themes or recurring issues. For example, if multiple customers complain about the same issue, such as a faulty component or poor customer service, this could be a red flag.

However, it’s also important to take customer reviews with a grain of salt. Some customers may have unrealistic expectations or use the machine improperly, leading to negative reviews. Therefore, it’s a good idea to read a variety of reviews and consider the overall rating of the product.

The Need for Warranty and After-Sales Service in Lathe Mill Combos

A warranty is a guarantee provided by the manufacturer that the product will be free from defects for a certain period of time. If the product fails during this period, the manufacturer will repair or replace it free of charge. A warranty can provide peace of mind and protect you from unexpected costs.

After-sales service refers to the support provided by the manufacturer after the purchase. This can include technical support, maintenance, and repairs. Good after-sales service can make the difference between a smooth and frustrating experience with a product.

When choosing a lathe mill combo, it’s important to consider the warranty and after-sales service provided by the manufacturer. A machine with a long warranty and good after-sales service is likely to be a safer bet than one without.

Conclusion: Making the Right Choice for Your Lathe Mill Combo Needs

Choosing the right lathe mill combo can be a complex process, but by considering the factors discussed in this article, you can make an informed decision. It’s important to consider your needs, budget, and the reputation of the brand before making a purchase.

Remember, the best lathe mill combo is not necessarily the most expensive or the one with the most features. It’s the one that fits your needs, is within your budget, and comes from a reputable brand. By doing your research and considering your options carefully, you can find a lathe mill combo that will serve you well for many years to come.

Finally, remember that safety should always be your top priority when using any type of machinery. Always read and understand the operator’s manual, use the machine as instructed, and wear appropriate safety gear. With the right machine and the right safety precautions, you can enjoy the benefits of a lathe mill combo and take your machining skills to the next level.