Jigsaw blades are a must-have for precision cutting in a variety of materials, from wood and metal to ceramic and plastic. These versatile blades come in different types and sizes, allowing you to tackle a wide range of projects, from intricate curves to straight cuts. Designed to work with jigsaws, they deliver smooth, accurate results with minimal vibration, making them perfect for both DIY enthusiasts and professionals.

Available in various tooth configurations—such as fine, coarse, or bi-metal—jigsaw blades ensure optimal performance for specific materials and cutting tasks. Whether you’re cutting through hardwood, sheet metal, or tile, there’s a blade that fits your needs.

With the right jigsaw blade, you can achieve clean, precise cuts with ease, making it an indispensable tool for any serious crafter or builder.

Our Top Jigsaw Blades Picks

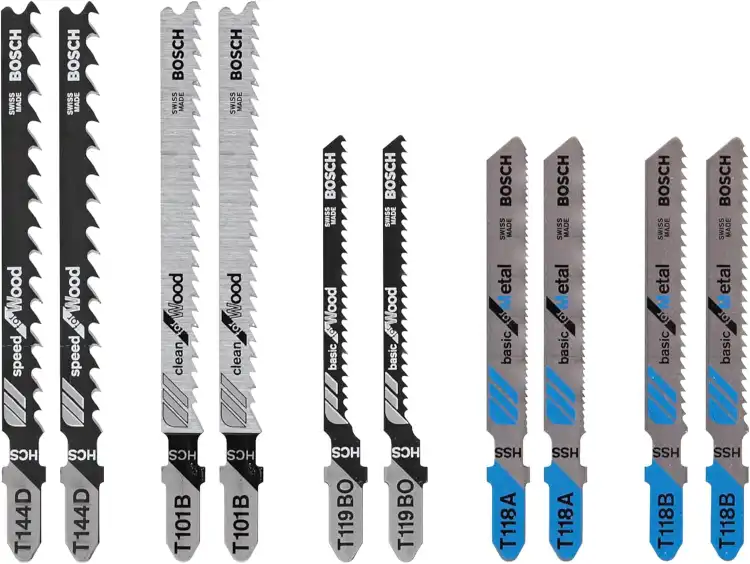

BOSCH T5002 T-Shank Multi-Purpose Jigsaw Blades

Check on Amazon

Key Specs

- Material: Metal

- Teeth Count: 10 per blade

- Compatibility: Fits Bosch, DEWALT, Hitachi, Makita, Milwaukee, Metabo, Porter-Cable, and Craftsman jigsaws

- Blade Types: Wood and Metal Cutting

- Storage: Comes with a durable plastic case

The Bosch T5002 T-Shank Multi-Purpose Jigsaw Blades set is a must-have for any serious DIYer or professional. The versatility of this set is unmatched, offering an ideal range of blades for both wood and metal cutting. The T-shank design ensures a secure grip and smooth cuts without the hassle of screw mounting. Plus, the inclusion of various teeth per inch (TPI) blades gives you perfect options for both fine and coarse cuts. The blades are durable, easy to store, and compatible with most jigsaws.

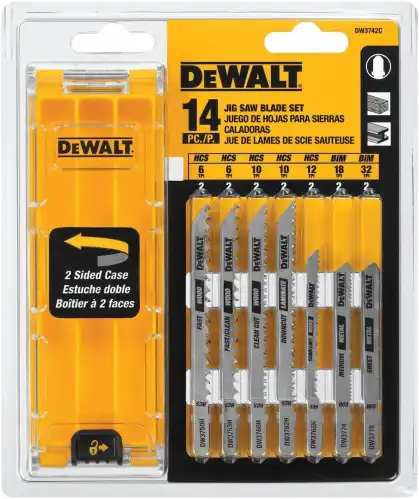

DEWALT Jigsaw Blades

Check on Amazon

Key Specs:

- Material: Blend

- Number of Teeth: 18 per blade

- Compatibility: Fits Bosch and DEWALT jigsaws

- Applications: Suitable for wood and metal cutting

- Set Size: 14 pieces

The DEWALT Jigsaw Blades set is perfect for those looking to tackle both wood and metal cutting projects. With a durable T-shank design, these blades provide a secure fit for all Bosch and DEWALT jigsaws, ensuring stability and precision. The 14-piece set includes various blade types to handle different applications, making it a versatile choice for any project. These blades are known for their longevity and ability to maintain sharpness through demanding tasks.

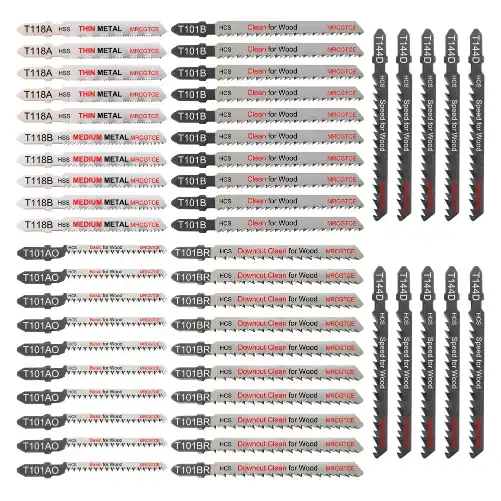

MRCGTCE 50 Piece Contractor Jigsaw Blades

Check on Amazon

Key Specs:

- Material: High-Speed Steel, Tungsten Carbide, High Carbon Steel

- Number of Teeth: 144 teeth across all blades

- Blade Types: Includes T118A, T118B, T101AO, T101B, T101BR, T144D

- Compatibility: Fits BOSCH and DEWALT jigsaws

- Storage: Comes with a durable storage case

The MRCGTCE 50 Piece Contractor Jigsaw Blades set offers exceptional value, providing high-quality blades at a fraction of the cost of name brands. With blades made from a combination of high-speed steel, tungsten carbide, and high-carbon steel, this set is built to last through tough materials like wood and metal. It includes a variety of blades to suit different cutting needs, from thin metal to wood, ensuring versatility and efficiency on every project. The included durable storage case makes organization easy, keeping your blades accessible when needed.

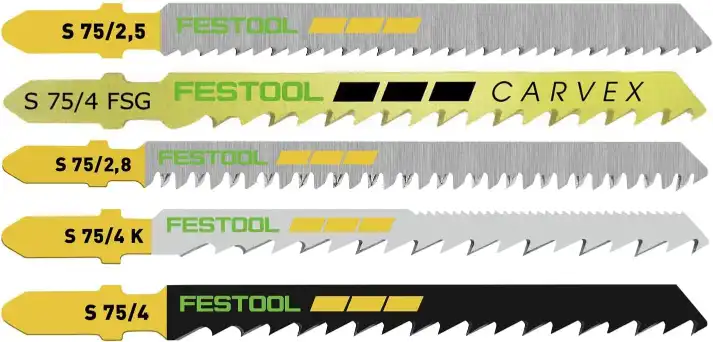

Festool 204275 Jigsaw Blade

Check on Amazon

Key Specs:

- Material: Tungsten Carbide, High-Grade HCS Tool Steel

- Compatibility: T-shank blades

- Item Weight: 6.4 ounces

- Product Dimensions: 9.1″ L x 9.1″ W

- Application: Ideal for cutting wooden materials

The Festool 204275 Jigsaw Blade is designed for precision and durability, delivering exceptional results when cutting wooden materials. Made from high-quality HCS tool steel, this blade ensures clean, smooth cuts with great efficiency. The tungsten carbide material enhances its longevity, making it a reliable choice for long-term use. Compatible with T-shank jigsaws, this blade is ideal for woodworkers seeking accurate cuts in high-grade wooden materials.

Vin Beauty 20 Piece Jigsaw Blades

Check on AmazonKey Specs:

- Material: High-Speed Steel

- Item Weight: 0.1 kilograms

- Product Dimensions: 6.3″ L x 2.36″ W

- Blade Types: T144D, T119BO, T101B, T118A, T118B (4 pieces of each)

- Application: Compatible with wood, metal, plastic, and more

The Vin Beauty 20 Piece Jigsaw Blades set provides excellent value with its variety of blades designed for versatile cutting tasks. Made from high-speed steel, these blades deliver clean, precise cuts while resisting wear and tear for enhanced durability. The T-shank design ensures stability, easy installation, and eliminates the need for screw mounting, preventing potential damage to your equipment. This set is compatible with most electric jigsaws, making it a reliable choice for various materials, from hardwood to metal.

Understanding the Importance of Jigsaw Blades in Woodworking

Jigsaw blades play a pivotal role in woodworking. They are used to make both straight and curved cuts, allowing for a high degree of versatility. The precision of these blades makes them ideal for creating intricate designs and patterns, a common requirement in woodworking.

Furthermore, the quality of a jigsaw blade can significantly impact the final product. A sharp, high-quality blade will produce clean, smooth cuts, reducing the need for additional sanding or finishing. On the other hand, a dull or low-quality blade can result in rough, jagged cuts, potentially ruining the piece of work.

Therefore, investing in good quality jigsaw blades is essential for any woodworker. Not only will they make the process of cutting easier and more efficient, but they will also contribute to the overall quality of your woodworking projects.

Different Types of Jigsaw Blades

There are several types of jigsaw blades available on the market, each designed for a specific purpose. The most common types include wood-cutting blades, metal-cutting blades, and scrolling blades. Wood-cutting blades have large, sharp teeth that can quickly cut through wood, while metal-cutting blades have smaller, finer teeth. Scrolling blades are narrow and designed for making intricate curved cuts.

Other types of jigsaw blades include reverse-tooth blades, flush-cutting blades, and diamond-grit blades. Reverse-tooth blades are designed to cut on the downstroke, reducing chipping on the top surface of the material. Flush-cutting blades have offset teeth that allow for cuts flush against a surface. Diamond-grit blades are used for cutting through tough materials like glass or ceramic tile.

Understanding the different types of jigsaw blades and their uses can help you choose the right blade for your project. It’s important to remember that not all blades are created equal, and the type of blade you choose can significantly impact the quality of your cuts.

Factors to Consider When Buying Jigsaw Blades

When buying jigsaw blades, several factors need to be considered. One of the most important is the type of material you plan to cut. Different blades are designed for different materials, so it’s crucial to choose a blade that’s suitable for your project. For example, if you’re cutting wood, you’ll need a blade with large, sharp teeth, while for metal, you’ll need a blade with smaller, finer teeth.

Another important factor is the type of cut you plan to make. If you’re making straight cuts, a standard blade should suffice. However, if you’re making curved or intricate cuts, you’ll need a scrolling blade. The thickness of the material you’re cutting is also important. Thicker materials require longer blades, while thinner materials can be cut with shorter blades.

Finally, consider the quality of the blade. High-quality blades are typically made from durable materials like high-carbon steel or tungsten carbide, ensuring long-lasting performance. While these blades may be more expensive, they are often worth the investment as they can produce cleaner, smoother cuts and last longer.

Understanding the Material of Jigsaw Blades

Jigsaw blades are typically made from one of three materials: high-carbon steel (HCS), high-speed steel (HSS), or tungsten carbide. Each material has its own set of advantages and disadvantages, and the best one for you will depend on your specific needs and the type of project you’re working on.

HCS blades are flexible and less likely to break, making them ideal for cutting softer materials like wood and plastic. However, they tend to dull quickly when used to cut harder materials. HSS blades, on the other hand, are more durable and can withstand higher temperatures, making them suitable for cutting harder materials like metal. However, they are less flexible and more prone to breaking.

Tungsten carbide blades are the most durable of the three. They are extremely hard and can cut through almost any material, including ceramic and glass. However, they are also the most expensive. Understanding the properties of each material can help you choose the right jigsaw blade for your project.

The Role of Blade Teeth in Cutting Different Materials

The teeth of a jigsaw blade play a crucial role in determining how well it cuts through different materials. The size, shape, and spacing of the teeth can all impact the quality of the cut.

Larger teeth are typically used for cutting through softer materials like wood. They remove more material with each stroke, allowing for faster cutting. However, they also tend to produce rougher cuts. Smaller teeth, on the other hand, are used for cutting harder materials like metal. They remove less material with each stroke, resulting in slower cutting, but produce smoother cuts.

The shape of the teeth can also impact the quality of the cut. For example, reverse-tooth blades have teeth that point downwards, reducing chipping on the top surface of the material. Understanding the role of blade teeth in cutting different materials can help you choose the right jigsaw blade for your project.

Importance of Blade Size and Thickness

The size and thickness of a jigsaw blade can significantly impact its performance. Larger blades are typically used for cutting through thicker materials, while smaller blades are used for thinner materials. The size of the blade can also affect the type of cut you can make. For example, larger blades are better suited for straight cuts, while smaller blades are better for curved or intricate cuts.

The thickness of the blade can also impact its performance. Thicker blades are more rigid and can withstand more pressure, making them ideal for cutting harder materials. However, they are also less flexible and may not be suitable for making curved cuts. Thinner blades, on the other hand, are more flexible and can make more intricate cuts, but they may not be as durable or able to cut through harder materials.

Therefore, when choosing a jigsaw blade, it’s important to consider both its size and thickness. These factors can significantly impact the quality of your cuts and the overall success of your project.

The Significance of Blade Shank Type

The shank of a jigsaw blade is the part that connects the blade to the jigsaw. There are two main types of shanks: T-shank and U-shank. The type of shank you choose can impact the performance of your blade and the ease with which you can change blades.

T-shank blades are the most common type of jigsaw blade. They are easy to install and remove without the need for additional tools, making blade changes quick and easy. Furthermore, they offer superior grip and stability, resulting in more accurate cuts.

U-shank blades, on the other hand, are less common and typically require a screwdriver to install and remove. However, they are often cheaper than T-shank blades and can be a good option for those on a budget. Regardless of the type of shank you choose, it’s important to ensure that it is compatible with your jigsaw.

How to Choose the Right Jigsaw Blade for Your Project

Choosing the right jigsaw blade for your project can be a daunting task, given the wide variety of blades available. However, by considering a few key factors, you can make the process much easier.

Firstly, consider the type of material you will be cutting. Different blades are designed for different materials, so it’s crucial to choose a blade that’s suitable for your project. For example, if you’re cutting wood, you’ll need a blade with large, sharp teeth, while for metal, you’ll need a blade with smaller, finer teeth.

Secondly, consider the type of cut you plan to make. If you’re making straight cuts, a standard blade should suffice. However, if you’re making curved or intricate cuts, you’ll need a scrolling blade. Finally, consider the quality of the blade. High-quality blades are typically made from durable materials like high-carbon steel or tungsten carbide, ensuring long-lasting performance.

Safety Precautions When Using Jigsaw Blades

Using jigsaw blades can be dangerous if proper safety precautions are not taken. Here are some safety tips to keep in mind when using these blades.

Firstly, always wear protective gear, including safety glasses and gloves. This will protect your eyes from flying debris and your hands from accidental cuts. Secondly, ensure that the blade is securely attached to the jigsaw before starting the cut. A loose blade can cause the jigsaw to kick back, potentially leading to injury.

Thirdly, never force the blade through the material. This can cause the blade to break or the jigsaw to kick back. Instead, let the blade do the work and guide it gently through the material. Finally, always unplug the jigsaw when changing blades to prevent accidental activation.

Maintaining and Cleaning Your Jigsaw Blades

Maintaining and cleaning your jigsaw blades is crucial for ensuring their longevity and performance. Here are some tips on how to properly care for your blades.

Firstly, clean your blades after each use. This can be done using a soft cloth or brush to remove any dust or debris. If the blade is particularly dirty, you can use a mild detergent or blade cleaner. However, avoid using harsh chemicals as they can damage the blade.

Secondly, regularly check your blades for signs of wear or damage. If you notice any chips or cracks, it’s time to replace the blade. Finally, store your blades in a dry, cool place. This will prevent rust and other forms of corrosion, ensuring that your blades remain in good condition for longer.

Common Mistakes to Avoid When Buying Jigsaw Blades

When buying jigsaw blades, there are several common mistakes that you should avoid. One of the most common is buying the wrong type of blade for your project. Different blades are designed for different materials and cuts, so it’s crucial to choose a blade that’s suitable for your needs.

Another common mistake is buying cheap, low-quality blades. While these may seem like a good deal, they often dull quickly and can result in rough, jagged cuts. Instead, invest in high-quality blades made from durable materials. These may be more expensive, but they will last longer and produce cleaner, smoother cuts.

Finally, many people forget to consider the type of shank when buying jigsaw blades. The type of shank can impact the ease with which you can change blades and the performance of your blade. Therefore, it’s important to choose a shank that’s compatible with your jigsaw and suitable for your needs.

The Impact of Brand and Price on Jigsaw Blade Quality

The brand and price of a jigsaw blade can have a significant impact on its quality. High-quality blades are typically more expensive, but they are often worth the investment. They are made from durable materials like high-carbon steel or tungsten carbide, ensuring long-lasting performance. Furthermore, they are designed to produce clean, smooth cuts, reducing the need for additional sanding or finishing.

On the other hand, cheaper blades are often made from less durable materials and can dull quickly. They may also produce rough, jagged cuts, potentially ruining your project. Therefore, while it may be tempting to save money by buying cheaper blades, it’s often a false economy in the long run.

When it comes to brand, it’s worth investing in blades from reputable manufacturers. These companies have a track record of producing high-quality blades and often offer better customer service and warranties. However, it’s also worth reading reviews and doing your own research to find the best blades for your needs.

The Environmental Impact of Jigsaw Blades

The environmental impact of jigsaw blades is often overlooked. However, like all products, they have an environmental footprint that can be reduced through careful use and disposal.

One of the main environmental impacts of jigsaw blades is the resources used in their production. This includes the raw materials used to make the blades, as well as the energy used in the manufacturing process. By choosing high-quality blades that last longer, you can reduce the need for replacement blades, thereby reducing the resources used.

Furthermore, jigsaw blades can be recycled at the end of their life, reducing the amount of waste that goes to landfill. However, not all recycling facilities accept jigsaw blades, so it’s important to check with your local facility before disposing of your blades. By considering the environmental impact of your jigsaw blades, you can make more sustainable choices.

Conclusion: Making the Right Choice for Your Jigsaw Blades

Choosing the right jigsaw blade for your project can be a daunting task, given the wide variety of blades available. However, by considering factors such as the type of material you’re cutting, the type of cut you’re making, and the quality of the blade, you can make the process much easier.

Remember, investing in high-quality blades can significantly improve the quality of your cuts and the overall success of your project. Furthermore, proper maintenance and cleaning can extend the life of your blades, ensuring that you get the most out of your investment.

Finally, consider the environmental impact of your blades. By choosing long-lasting blades and recycling them at the end of their life, you can reduce your environmental footprint. With the right knowledge and care, you can make the most of your jigsaw blades and achieve great results in your woodworking projects.

FAQ

What are jigsaw blades made of?

Jigsaw blades are typically made from high-carbon steel (HCS), high-speed steel (HSS), or tungsten carbide. Each material has its own set of advantages and disadvantages.

How do I choose the right jigsaw blade for my project?

Consider the type of material you’re cutting, the type of cut you’re making, and the quality of the blade. Different blades are designed for different materials and cuts, so it’s crucial to choose a blade that’s suitable for your needs.

How do I maintain and clean my jigsaw blades?

Clean your blades after each use using a soft cloth or brush. Regularly check your blades for signs of wear or damage and replace them if necessary. Store your blades in a dry, cool place to prevent rust and corrosion.