Impact sockets are essential tools for anyone working with high-torque power tools, ensuring durability and precision when tightening or loosening tough bolts. Unlike standard sockets, impact sockets are made from stronger materials, like chrome-molybdenum steel, to withstand the intense force generated by impact wrenches and drivers. These sockets are designed to prevent cracking or splitting, even during the toughest jobs.

Perfect for automotive repairs, construction, and heavy-duty maintenance, impact sockets come in a variety of sizes and drive types to suit different applications. The deep well and thin wall designs allow for greater accessibility, even in tight spaces.

Whether you’re a professional mechanic or a DIY enthusiast, investing in high-quality impact sockets ensures that your power tools perform at their best, providing safety and efficiency for all your demanding projects.

Our Top Impact Sockets Buying Guide Picks

DEWALT Impact Socket Set

Check on Amazon

Key Specs

- Material: Blend (Heat-treated CR-440 Steel)

- Drive System: Torx

- Finish Type: Polished

- Number of Pieces: 23

- Technology: DirectTorque for improved grip

The DEWALT Impact Socket Set is designed for durability and performance. Its DirectTorque Technology prevents rounding of fasteners, ensuring a better grip. The sockets feature laser-etched markings for easy identification, making it efficient for mechanics or DIYers. The set is compatible with O-ring and retaining pin systems, adding to its versatility. Made from heat-treated CR-440 steel, these impact-ready sockets offer long-lasting strength for tough jobs.

Neiko 02447A 1/2″ Drive Master Impact Socket

Check on AmazonKey Specs:

- Material: Chrome Vanadium Steel

- Drive System: Hex

- Finish Type: Black Phosphate (Corrosion-resistant)

- Number of Pieces: 32

- Inclusions: 29 sockets, 2 extension bars, 1 adapter

The Neiko 02447A 1/2″ Drive Master Impact Socket Set is crafted from chrome vanadium steel, making it a durable and high-quality choice for automotive and mechanical tasks. Its 6-point hex socket design prevents rounding off of nuts and bolts under high torque and impact wrench use. The black phosphate coating offers corrosion resistance and longevity, while the laser-etched markings provide easy size identification. With a variety of sizes, including both SAE and metric, this set is perfect for tackling a wide range of automotive jobs.

GEARWRENCH 19 Pc. 1/2″ Drive 6 Point Deep Impact SAE Socket

Check on Amazon

Key Specs:

- Material: Chrome Molybdenum Steel

- Finish Type: Black Oxide

- Number of Pieces: 19

- Drive Size: 1/2″

- Corrosion Resistance: Manganese Phosphate Coating

The GEARWRENCH 19 Pc. 1/2″ Drive 6 Point Deep Impact SAE Socket set is made from chrome molybdenum steel (CR-MO), providing superior strength and durability for tough tasks. The off-corner loading technology helps reduce fastener rounding, making it reliable for heavy use. With a black phosphate finish and manganese phosphate coating, these sockets are resistant to corrosion and wear. The laser-etched markings offer easy size identification, making this set an excellent choice for professionals in need of long-lasting, high-performance tools.

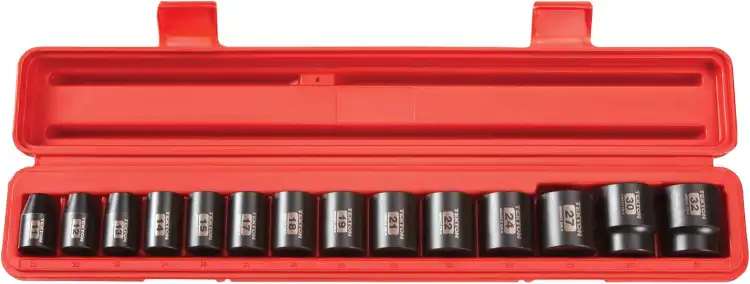

TEKTON 1/2 Inch Drive 6-Point Impact Socket Set

Check on AmazonKey Specs:

- Material: Chrome Vanadium Steel

- Number of Pieces: 14

- Drive Size: 1/2″

- Finish: Black Phosphate Corrosion-Resistant

- Design: 6-Point Socket for Better Grip

The TEKTON 1/2 Inch Drive 6-Point Impact Socket Set is made from forged and heat-treated chrome vanadium steel, ensuring outstanding durability for heavy-duty applications. Its 6-point socket design provides a secure grip on the flat sides of fasteners, reducing the risk of rounding under high torque. The black phosphate finish offers superior corrosion resistance, while the high-contrast laser-etched size markings make it easy to identify the right socket, even in low-light conditions. With 14 sockets in metric sizes, this set is perfect for accessing fasteners in tight spaces.

NEIKO 02446A 1/2″ Impact Socket

Check on Amazon

Key Specs:

- Material: Chrome Vanadium Steel

- Number of Pieces: 35

- Drive Size: 1/2″

- Finish: Black Phosphate Coating

- Design: 6-Point Hex Socket

The NEIKO 02446A 1/2″ Impact Socket Set is built for heavy-duty tasks, made from chrome vanadium Cr-V steel to endure high torque forces. Its 6-point hex socket design prevents fastener rounding during impact use, making it ideal for automotive applications. This 35-piece set includes both metric and SAE sizes, each with a black phosphate coating for enhanced durability and protection. High-visibility laser-etched markings ensure easy size identification, while the set also includes essential accessories like extension bars, ratchet handle, and impact adapters.

Understanding the Importance of Impact Sockets

Impact sockets play a vital role in various industries, including automotive, construction, and manufacturing. They are designed to handle the high torque produced by impact tools, which is crucial when dealing with stubborn or rusted fasteners. Using a regular socket with an impact tool can lead to the socket shattering or the fastener getting damaged, which can result in injury or equipment damage.

Furthermore, impact sockets are designed to grip onto fasteners more securely than regular sockets. This reduces the risk of the socket slipping off the fastener during use, which can lead to accidents. Therefore, using impact sockets can enhance the safety and efficiency of your work.

Lastly, impact sockets are typically more durable than regular sockets due to their robust construction. This means that they can withstand repeated use over a long period, making them a cost-effective choice for professionals and DIY enthusiasts alike.

Differentiating Between Impact Sockets and Regular Sockets

While impact sockets and regular sockets may look similar, there are key differences between them that affect their functionality and suitability for different tasks. One of the main differences is the material they are made from. Impact sockets are typically made from a softer, more flexible material such as chrome-molybdenum steel, which can withstand the high torque produced by impact tools.

On the other hand, regular sockets are usually made from a harder material like chrome-vanadium steel. While this material is durable and can handle high levels of force, it is more brittle than the material used in impact sockets and can shatter if used with an impact tool.

Another key difference is the thickness of the socket wall. Impact sockets have thicker walls to absorb the impact force, while regular sockets have thinner walls to allow for better access in tight spaces. This means that impact sockets are more durable, but they may not fit in tight spaces where a regular socket would.

Key Features to Look for in Impact Sockets

When buying impact sockets, there are several key features to look for to ensure you get a tool that will serve you well. One of these features is the socket size. Impact sockets come in a variety of sizes to fit different fasteners, so it’s important to choose a socket that fits your specific needs.

Another important feature is the drive size. This refers to the size of the square hole in the socket that connects to the impact tool. Common drive sizes include 1/4 inch, 3/8 inch, 1/2 inch, 3/4 inch, and 1 inch. The drive size you choose should match the drive size of your impact tool for the socket to fit properly.

Lastly, consider the socket depth. Impact sockets come in two main types: deep and shallow. Deep sockets are longer and can reach fasteners that are located in deep recesses, while shallow sockets are shorter and are ideal for fasteners that are easily accessible.

Understanding the Material and Construction of Impact Sockets

Impact sockets are typically made from chrome-molybdenum steel, a material known for its strength and durability. This material can withstand the high torque produced by impact tools without shattering, making it ideal for impact sockets. The sockets are also heat-treated to enhance their durability and resistance to wear and tear.

The construction of impact sockets also sets them apart from regular sockets. They have thicker walls to absorb the impact force, and they often have a black oxide finish to prevent corrosion. Some impact sockets also have a pin hole or a retaining ring to secure the socket to the impact tool, preventing it from slipping off during use.

It’s also worth noting that impact sockets are typically six-point, meaning they have six points of contact with the fastener. This provides a better grip and reduces the risk of rounding the fastener compared to twelve-point sockets, which have twelve points of contact.

The Role of Size and Shape in Choosing Impact Sockets

The size and shape of an impact socket are crucial factors to consider when choosing a socket. The size of the socket should match the size of the fastener you are working with. Using a socket that is too large or too small can damage the fastener or the socket itself. Impact sockets come in a variety of sizes, from small 1/4 inch sockets to large 1 inch sockets, so you can find a socket that fits your specific needs.

The shape of the socket also plays a role in its functionality. Most impact sockets are six-point, meaning they have six points of contact with the fastener. This provides a better grip and reduces the risk of rounding the fastener. However, there are also twelve-point impact sockets available, which provide more points of contact and can be used with fasteners that have twelve points.

Furthermore, the shape of the socket can affect its accessibility. Deep sockets are longer and can reach fasteners that are located in deep recesses, while shallow sockets are shorter and are ideal for fasteners that are easily accessible. Therefore, the shape of the socket you choose should depend on the location and accessibility of the fastener you are working with.

Importance of Socket Depth: Deep vs. Shallow Sockets

Socket depth is a crucial factor to consider when choosing an impact socket. Deep sockets are longer and can reach fasteners that are located in deep recesses or behind other components. This makes them ideal for tasks such as removing spark plugs or bolts that are located in tight spaces.

On the other hand, shallow sockets are shorter and are ideal for fasteners that are easily accessible. They are also lighter and easier to handle than deep sockets, making them a good choice for tasks that require speed and precision.

It’s worth noting that the depth of the socket can affect its durability. Deep sockets have more material and are therefore typically more durable than shallow sockets. However, shallow sockets are often sufficient for most tasks, and they are usually more affordable than deep sockets.

The Relevance of Drive Size in Impact Sockets

The drive size of an impact socket refers to the size of the square hole in the socket that connects to the impact tool. This is a crucial factor to consider when choosing an impact socket, as the drive size should match the drive size of your impact tool for the socket to fit properly.

Common drive sizes include 1/4 inch, 3/8 inch, 1/2 inch, 3/4 inch, and 1 inch. Smaller drive sizes are suitable for light-duty tasks and smaller fasteners, while larger drive sizes are ideal for heavy-duty tasks and larger fasteners.

It’s also worth noting that the drive size can affect the torque that the socket can handle. Larger drive sizes can handle more torque than smaller drive sizes, making them a better choice for tasks that require a high amount of force.

Impact Socket Set: Why You Might Need One

An impact socket set is a collection of impact sockets of various sizes and types. Having a set of impact sockets can be beneficial for several reasons. First, it ensures that you have the right size of socket for any task. This can save you time and effort, as you won’t have to stop your work to find or buy the right size of socket.

Second, an impact socket set can be more cost-effective than buying individual sockets. The cost per socket is usually lower when you buy a set, making it a good investment if you frequently use impact sockets.

Lastly, most impact socket sets come with a storage case, which makes it easy to organize and transport your sockets. This can prevent your sockets from getting lost or damaged, and it can make your work more efficient as you can easily find the socket you need.

The Role of Impact Sockets in Different Industries

Impact sockets play a crucial role in various industries, including automotive, construction, and manufacturing. In the automotive industry, impact sockets are used to remove and install lug nuts, bolts, and other fasteners. They are also used in engine repair and maintenance tasks, such as removing spark plugs or cylinder head bolts.

In the construction industry, impact sockets are used in tasks such as assembling and disassembling structures, installing and removing fasteners, and tightening and loosening bolts and nuts. They are also used in heavy equipment maintenance and repair tasks.

In the manufacturing industry, impact sockets are used in assembly lines to install and remove fasteners quickly and efficiently. They are also used in maintenance and repair tasks to keep machinery and equipment running smoothly.

Safety Considerations When Using Impact Sockets

While impact sockets are designed to handle the high torque produced by impact tools, it’s important to use them safely to prevent accidents and injuries. One of the main safety considerations is to always use the right size of socket for the fastener. Using a socket that is too large or too small can cause the socket to slip off the fastener, which can lead to accidents.

Another safety consideration is to always secure the socket to the impact tool properly. Most impact sockets have a pin hole or a retaining ring to secure the socket to the tool. Make sure to use these features to prevent the socket from slipping off during use.

Lastly, always wear protective gear when using impact sockets. This includes safety glasses to protect your eyes from flying debris, gloves to protect your hands, and sturdy footwear to protect your feet.

Maintenance and Care for Impact Sockets

Proper maintenance and care can extend the lifespan of your impact sockets and keep them in good working condition. One of the main aspects of maintenance is cleaning. After each use, wipe off any dirt or grease from the socket with a clean cloth. If the socket is very dirty, you can use a mild detergent and a brush to clean it, then dry it thoroughly to prevent rust.

Another aspect of maintenance is storage. Store your impact sockets in a dry, cool place to prevent rust and corrosion. Most impact socket sets come with a storage case, which makes it easy to organize and store your sockets.

Lastly, inspect your impact sockets regularly for any signs of wear or damage. If a socket is cracked, chipped, or otherwise damaged, replace it immediately to prevent accidents and injuries.

Understanding the Pricing of Impact Sockets

The price of impact sockets can vary widely depending on several factors. One of these factors is the size of the socket. Larger sockets are typically more expensive than smaller sockets due to the amount of material used in their construction.

Another factor that affects the price is the brand. Well-known brands that are known for their quality and durability often charge more for their products. However, this doesn’t mean that less expensive brands are of poor quality. Many affordable brands offer high-quality impact sockets that can serve you well.

Lastly, the type of socket can affect its price. Deep sockets are usually more expensive than shallow sockets due to their larger size and increased durability. Similarly, impact socket sets are usually more expensive than individual sockets, but they can be more cost-effective in the long run if you frequently use impact sockets.

Common Mistakes to Avoid When Buying Impact Sockets

When buying impact sockets, there are several common mistakes to avoid to ensure you get a tool that will serve you well. One of these mistakes is choosing the wrong size of socket. The size of the socket should match the size of the fastener you are working with. Using a socket that is too large or too small can damage the fastener or the socket itself.

Another common mistake is choosing the wrong drive size. The drive size of the socket should match the drive size of your impact tool for the socket to fit properly. Using a socket with the wrong drive size can cause the socket to slip off the tool during use, which can lead to accidents.

Lastly, don’t overlook the importance of the socket depth. Deep sockets can reach fasteners that are located in deep recesses, while shallow sockets are ideal for fasteners that are easily accessible. Choose the socket depth that fits your specific needs to ensure efficient and safe operation.

Conclusion: Making an Informed Decision When Buying Impact Sockets

Impact sockets are a crucial tool in various industries, and understanding their features and functionality can help you make an informed decision when buying them. Consider factors such as the socket size, drive size, socket depth, and the material and construction of the socket to ensure you get a tool that fits your specific needs.

Also, remember to use impact sockets safely to prevent accidents and injuries. Always use the right size of socket for the fastener, secure the socket to the impact tool properly, and wear protective gear when using impact sockets.

Lastly, take care of your impact sockets to extend their lifespan and keep them in good working condition. Clean them after each use, store them in a dry, cool place, and inspect them regularly for any signs of wear or damage. With proper care and maintenance, your impact sockets can serve you well for a long time.

FAQs

What is the difference between impact sockets and regular sockets?

Impact sockets are made from a softer, more flexible material that can withstand the high torque produced by impact tools. They also have thicker walls to absorb the impact force. Regular sockets, on the other hand, are made from a harder, more brittle material and have thinner walls.

What should I look for when buying impact sockets?

Consider factors such as the socket size, drive size, socket depth, and the material and construction of the socket. Also, consider whether you need a deep or shallow socket based on the location and accessibility of the fastener you are working with.

How should I care for my impact sockets?

Clean your impact sockets after each use, store them in a dry, cool place, and inspect them regularly for any signs of wear or damage. If a socket is damaged, replace it immediately to prevent accidents and injuries.