Hand saws, the quintessential tool of any craftsman, have been a staple in woodworking and construction for centuries. These traditional cutting tools, despite the advent of power tools, continue to hold a significant place in the world of carpentry and DIY projects. Their simplicity, versatility, and precision make them an indispensable tool in any toolbox.

Hand saws come in a variety of shapes and sizes, each designed for a specific purpose. From cutting intricate shapes to slicing through thick logs, these tools have been instrumental in shaping our built environment. The importance of hand saws cannot be overstated. They are a testament to human ingenuity and the enduring value of traditional craftsmanship.

Despite their seeming simplicity, hand saws are complex tools with a rich history and a wide range of types and designs. This article aims to provide a comprehensive overview of hand saws, from their history and types to their anatomy, materials, and usage. It will also delve into the importance of choosing the right hand saw, safety measures, maintenance, top brands, and the future of hand saws.

Our Top Hand Saw Wood Picks

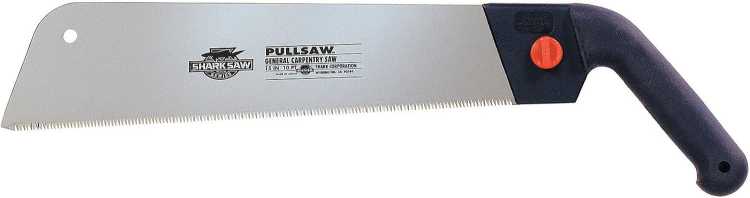

Shark Corporation 10-2315 Carpentry Saw

Check on AmazonKey Specs

- Blade Material: Alloy steel

- Cutting Type: Pull stroke for more accurate cuts

- Surface Suitability: Hard/soft woods, plywood, plastic pipe, drywall, and more

- Handle Type: Comfortable pistol grip

- Warranty: 1-year warranty

The Shark Corporation 10-2315 Carpentry Saw is a versatile and efficient tool for both professionals and DIY enthusiasts. Featuring a pull stroke design, this saw ensures more precise and controlled cuts, reducing binding and providing a safer, smoother start. The aggressive tooth design makes cutting through hard and soft woods, treated lumber, plywood, particle board, drywall, and plastic pipe quick and easy. With a comfortable pistol grip handle, this saw is a reliable choice for a variety of carpentry tasks.

IRWIN Tools General Carpentry Pull Saw

Check on AmazonKey Specs:

- Blade Material: High-speed steel

- Blade Length: 12 inches

- Teeth Count: 14 points

- Handle Type: ProTouch 2-polymer grip

- Ideal Use: Exterior trim work, gable soffit cutting

The IRWIN Tools General Carpentry Pull Saw is designed for precise cross-cuts and ripping, making it ideal for carpenters and DIY enthusiasts. The flexible blade ensures smooth, flush cuts, while the ProTouch grip provides added comfort with its 2-polymer handle construction. Perfect for tasks like exterior trim work or cutting gable soffit overhangs, this saw features a 12″ blade with 14 points for optimal performance and control.

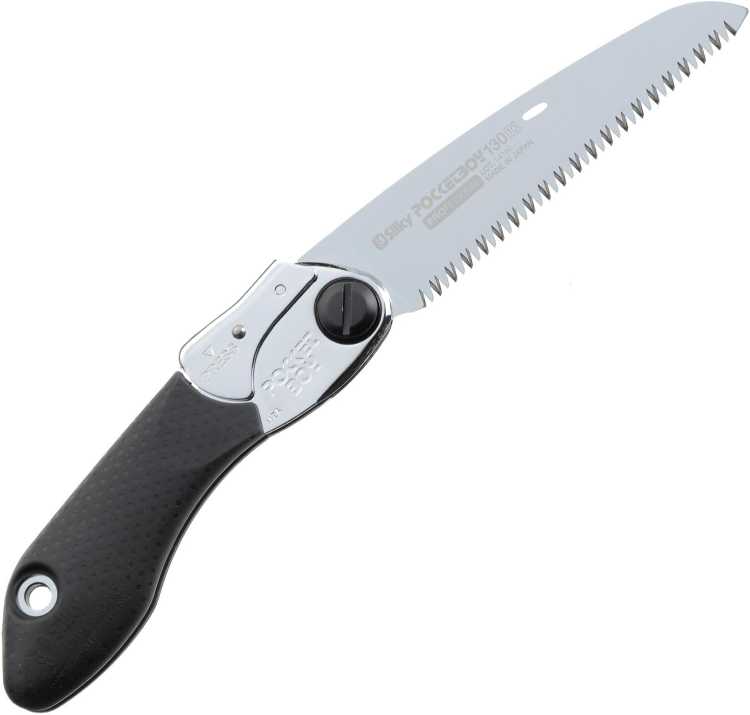

Silky Professional Series PocketBoy Folding Saw

Check on AmazonKey Specs:

- Blade Length: 130mm (5.1 inches)

- Blade Thickness: 1.4mm

- Teeth Configuration: 8.5 teeth per inch

- Cut Capacity: 2.6 inches

- Kerf: 1.3mm

The Silky Professional Series PocketBoy Folding Saw is a compact and lightweight tool designed for effortless cutting. Its rust-resistant, hard chrome-plated blade features taper-ground, impulse-hardened teeth for superior durability. With a 5.1-inch blade and 8.5 teeth per inch, it’s perfect for landscaping, pruning, camping, and trail maintenance. The saw also offers two open locking positions for versatile use, including flush or inline cutting. Ideal for both professionals and outdoor enthusiasts, it includes a hard plastic belt case for easy portability.

IRWIN Hand Saw

Check on AmazonKey Specs:

- M2 Tooth Technology and Tri-Ground Teeth for fast, efficient cuts

- Tapered-Pitch Nose for improved clearance and stability

- Deep Gullets for quick chip removal

- Thick-Body Blade for rigidity and control

- Pro-Touch Handle for comfort and durability

The IRWIN Hand Saw is designed for fast and efficient cutting, making it ideal for carpenters and DIY enthusiasts. It features M2 tooth technology and Tri-Ground teeth, which ensure smooth and rapid cuts. The tapered-pitch nose enhances clearance and stability during use, while the deep gullets quickly remove chips, preventing clogging. The thick-body blade provides added rigidity and control, allowing for precise cuts. For enhanced comfort and durability, it is equipped with a Pro-Touch handle.

Gyokucho 770-3600 Razor Ryoba Saw

Check on AmazonKey Specs:

- 2 Saw Functions in One: Finer side for crosscuts, coarser side for rips

- High-Speed Steel Blade for durability and precision

- 0.5mm Blade Thickness for a fine kerf, minimizing wood waste

- Traditional Japanese Pull-Stroke Saw design for smoother cuts and greater control

The Gyokucho 770-3600 Razor Ryoba Saw is a modern take on the traditional Japanese pull-stroke saw, offering versatility and precision for woodworking tasks. It features two saws in one, with a finer side designed for crosscut work and a coarser side for rip work. The 0.5mm thick blade provides an ultra-fine kerf, allowing for cleaner cuts with minimal wood loss. This saw is perfect for intricate woodwork and detailed projects, especially when working with plastic and other materials.

History of Hand Saws

The history of hand saws dates back to ancient times. The earliest evidence of saws can be traced back to the Neolithic period, around 4000 to 3000 BC. These primitive saws were made from flint and were used for cutting wood and bone. Over time, saws evolved, with the introduction of metal saws around 2000 BC marking a significant milestone in their development.

Hand saws have played a crucial role in the evolution of woodworking and construction. They have enabled craftsmen to cut and shape wood with precision, contributing to the development of everything from furniture and houses to ships and bridges. The impact of hand saws on these industries is immeasurable, and their importance remains undiminished even in the age of power tools.

Over the centuries, hand saws have evolved in design and materials, but their basic function has remained the same. Today, they continue to be a vital tool for carpenters, builders, and DIY enthusiasts, testament to their enduring utility and versatility.

Types of Hand Saws

Hand saws come in a variety of types, each designed for a specific task. The most common types include the rip saw, crosscut saw, backsaw, coping saw, and keyhole saw. Rip saws, with their large, chisel-like teeth, are designed for cutting along the grain of the wood. Crosscut saws, on the other hand, have smaller, knife-like teeth and are used for cutting across the grain.

Backsaws, which include tenon saws and dovetail saws, have a stiffening rib on the edge opposite the cutting edge and are used for precise cuts in woodworking. Coping saws, with their thin blades, are used for cutting intricate shapes or patterns. Keyhole saws, also known as compass saws, have a pointed, narrow blade and are used for cutting curves and circles.

Each type of hand saw has a specific use and is designed to make certain types of cuts more efficient and precise. Understanding the different types of hand saws and their uses is crucial for anyone involved in woodworking or construction, whether professionally or as a hobby.

Understanding Saw Teeth

The design of a saw’s teeth is a critical factor in its performance. The shape, size, and arrangement of the teeth determine the type of cut the saw can make and the material it can cut. For example, rip saws have large, chisel-like teeth designed to cut along the grain of the wood, while crosscut saws have smaller, knife-like teeth for cutting across the grain.

The teeth count per inch (TPI) is another important aspect of a saw’s design. The TPI determines how fine or coarse the cut will be. A higher TPI results in a finer cut, while a lower TPI results in a coarser cut. The TPI also affects the speed of the cut, with a higher TPI generally resulting in slower cuts.

Understanding the design of saw teeth and the importance of TPI is crucial for choosing the right saw for a particular task. It can also help improve the efficiency and quality of your cuts, whether you’re a professional carpenter or a DIY enthusiast.

Anatomy of a Hand Saw

A hand saw consists of several parts, each with a specific function. The main parts include the blade, handle, teeth, and back. The blade is the part of the saw that does the cutting. It is typically made of steel and can vary in length, width, and thickness depending on the type of saw.

The handle, usually made of wood or plastic, is designed to provide a comfortable grip for the user. The teeth, located on the cutting edge of the blade, are responsible for cutting the material. The back, found on some types of saws like the backsaw, is a stiffening rib that helps keep the blade straight during cutting.

Understanding the anatomy of a hand saw can help you use the tool more effectively and safely. It can also assist in troubleshooting any problems you may encounter while using the saw.

Materials Used in Hand Saws

Hand saws are typically made from a combination of metal and wood or plastic. The blade is usually made of steel, which provides the hardness and sharpness necessary for cutting. The type of steel used can vary, with high-carbon steel being a common choice due to its durability and ease of sharpening.

The handle is typically made of wood or plastic. Wood handles are favored for their comfort and aesthetic appeal, while plastic handles are appreciated for their durability and resistance to moisture. Some high-end hand saws may also feature handles made of exotic woods or composite materials.

The materials used in a hand saw can significantly impact its performance and longevity. High-quality materials can ensure a sharper, more durable blade and a more comfortable, durable handle. Therefore, considering the materials is an important factor when choosing a hand saw.

Choosing the Right Hand Saw

Choosing the right hand saw is crucial for achieving the best results in your woodworking or construction projects. Several factors should be considered when buying a hand saw, including the type of saw, the materials used, the design of the teeth, and the comfort of the handle.

The type of saw you choose should match the task at hand. For example, if you need to cut along the grain of the wood, a rip saw would be the best choice. If you need to make precise cuts in woodworking, a backsaw would be more suitable. The materials used in the saw can also affect its performance and longevity, so it’s worth investing in a saw made of high-quality materials.

The design of the teeth and the comfort of the handle are also important considerations. A saw with the right TPI for your task can improve the efficiency and quality of your cuts, while a comfortable handle can make the saw easier and safer to use.

Safety Measures When Using Hand Saws

Using a hand saw requires certain safety precautions to prevent accidents and injuries. These include wearing appropriate protective gear, such as safety glasses and gloves, and ensuring that the work area is clean and well-lit. It’s also important to use the saw correctly, following the manufacturer’s instructions and not forcing the saw during cutting.

Proper handling and storage of the saw are also crucial for safety. The saw should be held firmly but not tightly, with the index finger extended along the handle to guide the saw. When not in use, the saw should be stored in a safe place, with the blade protected to prevent accidents and damage to the teeth.

By following these safety measures, you can ensure that you use your hand saw safely and effectively, reducing the risk of accidents and injuries.

Maintenance and Care for Hand Saws

Proper maintenance and care can extend the life of your hand saw and ensure its optimal performance. This includes regular cleaning of the blade to remove any dirt or resin that may have accumulated during cutting. A mild detergent and a soft brush can be used for this purpose. After cleaning, the blade should be dried thoroughly to prevent rusting.

Regular maintenance also includes checking the teeth for damage and sharpening them as needed. A dull saw not only makes cutting more difficult but can also be dangerous, as it requires more force to use and is more likely to slip. Therefore, keeping the teeth sharp is crucial for the performance and safety of the saw.

Proper storage is also part of the care for hand saws. The saw should be stored in a dry place, with the blade protected to prevent damage to the teeth. By following these maintenance and care tips, you can keep your hand saw in good condition and ensure its longevity.

Top Hand Saw Brands

There are many hand saw manufacturers, but some brands stand out for their quality and reputation. These include Stanley, Bahco, Irwin, and Disston. Stanley, a well-known name in the tool industry, offers a wide range of hand saws known for their quality and durability. Bahco, a Swedish company, is renowned for its innovative designs and high-quality materials.

Irwin, another reputable brand, offers a variety of hand saws designed for efficiency and comfort. Disston, a historic American brand, is known for its high-quality, durable saws. Each of these brands offers a range of hand saws to suit different tasks and budgets, making it easier to find the right saw for your needs.

When comparing these brands, it’s important to consider not only the price but also the quality, performance, and features of their saws. This can help you make an informed decision and choose a hand saw that offers the best value for your money.

Eco-Friendly Hand Saws

As awareness of environmental issues grows, many tool manufacturers are making efforts to produce eco-friendly products. This includes hand saws made from sustainable materials or designed to be more energy-efficient. Some brands offering eco-friendly options include Bahco, with its range of biodegradable hand tools, and Stanley, with its commitment to reducing its environmental impact.

Choosing an eco-friendly hand saw can be a small but significant way to contribute to environmental sustainability. It’s not only good for the planet but can also be good for your health, as many eco-friendly tools are made without harmful chemicals.

However, it’s important to do your research and choose a truly eco-friendly product. Look for products made from sustainable materials, produced with energy-efficient processes, and packaged in recyclable or minimal packaging.

DIY Projects with Hand Saws

Hand saws are a versatile tool that can be used for a variety of DIY projects. These include building furniture, such as tables and chairs; creating garden structures, such as trellises and planters; and making home decor items, such as picture frames and shelves. With a hand saw, the possibilities are endless.

For beginners, it’s important to start with simple projects and gradually move on to more complex ones. It’s also crucial to learn how to use the hand saw properly and safely. This includes understanding the different types of cuts, learning how to hold the saw correctly, and knowing how to maintain the saw.

With patience and practice, you can use a hand saw to create beautiful and functional items for your home and garden. Not only can this save you money, but it can also give you a sense of accomplishment and satisfaction.

Future of Hand Saws

Despite the rise of power tools, hand saws continue to have a place in woodworking and construction. However, like all tools, they are subject to technological advancements and trends. One such trend is the increasing use of composite materials in the production of hand saws. These materials offer the potential for lighter, stronger, and more durable saws.

Another trend is the development of ergonomic designs for improved comfort and efficiency. This includes handles designed to reduce strain and fatigue, and blades designed for smoother, faster cuts. Some manufacturers are also exploring the use of advanced manufacturing techniques, such as 3D printing, to produce hand saws.

While it’s impossible to predict the future with certainty, it’s clear that hand saws will continue to evolve and adapt to the needs of craftsmen and DIY enthusiasts. Whatever the future holds, the importance of hand saws in woodworking and construction is likely to remain undiminished.

Conclusion

Hand saws, with their simplicity, versatility, and precision, are an integral part of any toolbox. Whether you’re a professional carpenter or a DIY enthusiast, understanding the different types of hand saws, their anatomy, and their uses can help you choose the right saw for your tasks and use it effectively and safely.

The importance of traditional cutting tools like hand saws cannot be overstated. Despite the advent of power tools, they continue to hold a significant place in woodworking and construction. They are a testament to human ingenuity and the enduring value of traditional craftsmanship.

As we look to the future, it’s clear that hand saws will continue to evolve and adapt to the needs of craftsmen and DIY enthusiasts. Whatever the future holds, the importance of hand saws in woodworking and construction is likely to remain undiminished.

FAQ

What is a hand saw for wood?

A hand saw for wood is a manual tool used for cutting through wood by using a serrated blade.

How do you use a hand saw for wood?

Position the saw at the desired cutting line, hold it firmly, and use a back-and-forth motion to cut through the wood.

What types of wood can a hand saw cut?

A hand saw can cut through various types of wood, including softwoods, hardwoods, and plywood.

Is a hand saw better than a power saw?

A hand saw is ideal for smaller, precise cuts, while a power saw is faster and more efficient for larger jobs.

How do I maintain a hand saw?

Keep the blade clean, sharpen the teeth regularly, and ensure the handle is secure for safety and optimal performance.