A flush-cut saw is an indispensable tool for precision cutting in tight spaces, designed to make smooth, flush cuts without damaging surrounding surfaces. Ideal for trimming dowels, nails, or other protrusions, this saw features a thin, flexible blade that allows you to cut as close to the surface as possible, leaving no excess material behind. The flush-cut design ensures that your cuts are clean and precise, making it perfect for fine woodworking, cabinetry, and detailed DIY projects.

The saw’s compact size and comfortable handle offer excellent control, making it easier to navigate intricate cuts. Whether you’re working with wood, plastic, or soft metals, a flush-cut saw allows you to achieve professional results with minimal effort.

If you’re looking to refine your woodworking skills or need a tool for tight, detailed cuts, a flush-cut saw is a must-have in your toolbox.

Our Top Flush-Cut Saw Picks

Japanese Flush Cut Saw

Check on AmazonKey Specs

- Blade Material: High Carbon Steel

- Handle Material: Beech wood with brass components

- Cutting Type: Pull-stroke

- Special Feature: Flush trim capability

- Made In: Japan

The Temple Tool Japanese Flush Cut Saw is perfect for precision cutting of pegs, wedges, and tenons flush to adjacent surfaces. Made with high-carbon steel, it maintains a sharp edge for long-lasting, smooth cuts. The pull-stroke design allows for easy control and thin kerf cuts. I particularly admire the solid wood handle, made of beech with brass components, offering both comfort and beauty. Handcrafted in Japan with over 100 years of craftsmanship, this saw ensures accuracy and durability in woodworking.

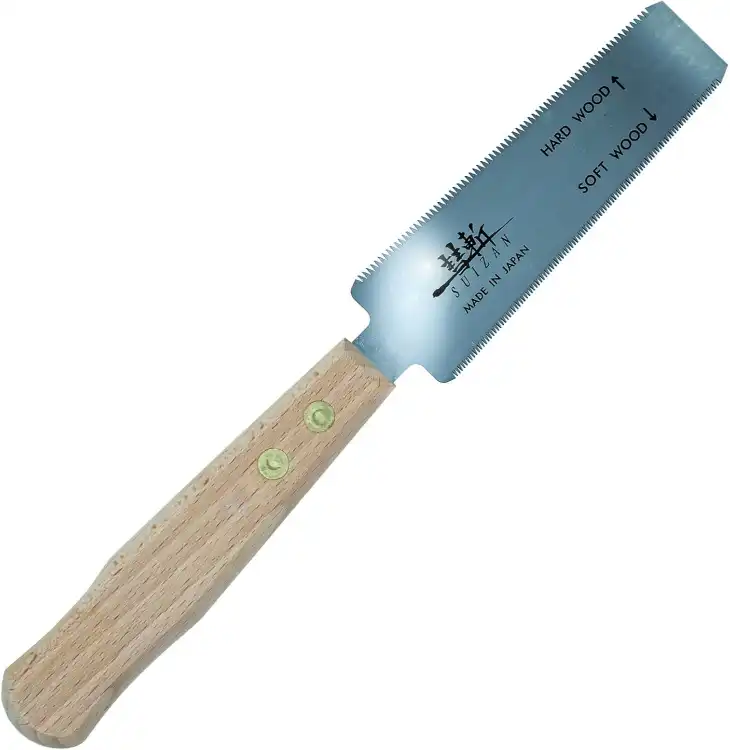

SUIZAN Flush Cut Saw

Check on AmazonKey Specs:

- Blade Material: Japanese Steel

- Cut Type: Pull stroke

- Surface Recommendation: Hardwood & Softwood

- Made In: Japan

- Non-replaceable blade

The SUIZAN Flush Cut Saw is an exceptional tool for woodworking, offering a Japanese-style pull saw design. Unlike European “push saws,” this pull saw cuts on the pull stroke, making it lighter, requiring less effort, and delivering cleaner edges. Made from high-quality Japanese steel, it ensures razor-sharp precision for both hardwoods like oak and softwoods like cedar. Crafted by Japanese master craftsmen with over 100 years of tradition, this saw brings an authentic, efficient cutting experience for both beginners and experts.

Clarke Brothers Flush Cut Saw

Check on Amazon

Key Specs:

- Blade Material: Stainless Steel

- Handle Material: Beech Wood with Black Rattan Cover

- Replacement Tools Included

- Design: Authentic Japanese Ryoba and Flush Cut Saw

- Surface Recommendation: Wood

The Clarke Brothers Flush Cut Saw brings premium-grade craftsmanship with its stainless steel blade and hard beech wood handle, ensuring both durability and comfort. Its superior grip handles allow for maximum maneuverability and safety during use, while the blade replacement tools make it easy to maintain. This authentic Japanese design combines beauty and practicality, featuring a black rattan handle cover and a black logo. Ideal for professionals and DIY enthusiasts alike, it’s perfect for precise woodworking and crafting.

Zett S-145 Flush Cutting Japanese handsaw

Check on AmazonKey Specs:

- Blade Length: 150 mm

- Pitch: 1.20 mm

- Thickness: 0.40 mm

- Kerf: 0.40 mm

- Surface Recommendation: Furniture

The Zett S-145 Flush Cutting Japanese Handsaw is designed for precision, making it ideal for trimming dowels, tenons, and other woodworking tasks. The high carbon steel blade ensures durability, while its thin kerf (0.40 mm) provides smooth, accurate cuts with minimal effort. With a 150 mm blade length and a 1.20 mm pitch, this saw offers excellent control for detailed work. Its compact size makes it a perfect tool for fine woodworking on furniture and smaller projects.

The ZENKEYZ Shoulder Brace provides targeted pain relief and support for a range of shoulder injuries, including rotator cuff tears, dislocations, and arthritis. Its compression design alleviates pain from tendonitis, sprains, and strains, promoting healing. The brace is soft on the skin and can be worn comfortably day or night, over or under clothing. With adjustable front and back straps, it offers a customizable fit. Additionally, the included pressure pad pocket can hold ice or heat packs for enhanced recovery, while an Ebook guides rehabilitation exercises.

The Ultimate Guide to Flush-Cut Saws

Introduction

A flush-cut saw is a specialized tool designed to make precise cuts flush with a surface, leaving no protrusions or uneven edges. It is commonly used in woodworking and carpentry for tasks that require clean and accurate cutting. The importance of using a flush-cut saw lies in its ability to create seamless finishes, especially in delicate projects where precision is key.

Types of Flush-Cut Saws

1.Traditional Flush-Cut Saw**: This type features a single-edge blade with fine teeth for smooth cutting.

2.Pull Saw: A pull saw has a flexible blade that cuts on the pull stroke, allowing for more control and accuracy.

3.Double-Edge Saw: The double-edge saw has teeth on both sides of the blade, making it versatile for various cutting angles.

Features of a Flush-Cut Saw

– Flexible Blade: Enables the saw to maneuver around tight corners and intricate details.

– Fine Teeth: Provide clean and precise cuts without splintering the material.

– Ergonomic Handle: Offers a comfortable grip for extended use without causing hand fatigue.

How to Use a Flush-Cut Saw

1.Proper Grip and Stance: Hold the saw firmly with both hands and maintain a stable stance for better control.

2.Positioning the Saw: Place the saw flat against the surface to ensure a flush cut.

3.Making the Cut: Start the cut with a gentle push or pull motion, letting the teeth do the work without applying excessive force.

Applications of a Flush-Cut Saw

– Woodworking: Ideal for trimming dowels, cutting trim pieces, or shaping intricate designs.

– Flooring Installation: Perfect for cutting baseboards or trimming laminate flooring.

– Trim Work: Essential for precise cuts on moldings, casings, or door frames.

Benefits of Using a Flush-Cut Saw

– Clean Cuts: Achieve smooth and seamless finishes without jagged edges.

– Precision: Make accurate cuts close to surfaces for a professional look.

– Versatility: Suitable for a wide range of cutting tasks in various materials.

When to Use a Flush-Cut Saw

– Trimming Dowels: Easily cut dowels flush with a surface for a seamless look.

– Cutting Protruding Nails: Safely trim nails sticking out without damaging surrounding materials.

– Removing Excess Material: Perfect for trimming excess wood, plastic, or metal flush with a surface.

Differences Between a Flush-Cut Saw and Other Saws

| Flush-Cut Saw vs. Pull Saw | Flush-Cut Saw vs. Coping Saw | Flush-Cut Saw vs. Dovetail Saw |

|—————————-|—————————–|——————————|

| Single-edge blade | Thin blade with fine teeth | Fine teeth for precise cuts |

| Flexible for tight spaces | Cuts curves and shapes | Specifically for dovetail joints |

| Ideal for flush cuts | Used for coping moldings | Designed for dovetail joinery |

Safety Precautions When Using a Flush-Cut Saw

1. Wearing Protective Gear: Always wear safety goggles and gloves to protect your eyes and hands.

2. Securing the Workpiece: Ensure the material is firmly held in place to prevent slips or accidents.

3. Keeping Fingers Away from the Blade: Maintain a safe distance from the cutting area to avoid injuries.

Maintenance of a Flush-Cut Saw

– Cleaning the Blade: Regularly remove sawdust and debris to prevent buildup and maintain cutting efficiency.

– Sharpening the Teeth: Keep the teeth sharp for clean cuts by using a saw file or professional sharpening service.

– Storing the Saw Properly: Store the saw in a dry place away from moisture to prevent rust and damage.

Common Mistakes When Using a Flush-Cut Saw

1.Applying Too Much Pressure: Let the saw do the work without forcing it through the material.

2. Incorrect Blade Angle: Ensure the blade is flat against the surface for a flush cut.

3.Rushing the Cut: Take your time to make precise cuts instead of rushing through the process.

Tips for Choosing the Right Flush-Cut Saw

– Considering the Blade Length: Choose a blade length suitable for the cutting tasks you frequently perform.

– Evaluating the Tooth Count: Select a saw with the appropriate tooth count for the material you work with.

– Checking the Handle Comfort: Opt for a saw with an ergonomic handle that fits comfortably in your hand for extended use.

Case Studies: Real-Life Examples of Using a Flush-Cut Saw

1. Furniture Making: Crafting custom furniture pieces often requires precise cuts for seamless joints and finishes.

2.Home Renovation Projects: Installing trim, baseboards, or molding in homes necessitates accurate cutting for a professional look.

3. Carpentry Work: Building structures or framing structures benefit from the clean and precise cuts of a flush-cut saw.

Conclusion

In conclusion, a flush-cut saw is a valuable tool for achieving clean and precise cuts in various woodworking and carpentry projects. By incorporating a flush-cut saw into your toolkit, you can elevate the quality of your work and tackle intricate tasks with ease. Embrace the versatility and precision of a flush-cut saw to enhance your craftsmanship and achieve professional results.

FAQ

How do I choose the right flush-cut saw for my projects?

When selecting a flush-cut saw, consider factors such as blade length, tooth count, and handle comfort to ensure it meets your cutting needs effectively.

Can a flush-cut saw be used for cutting metal materials?

While primarily designed for woodworking tasks, some flush-cut saws with specialized blades can cut through soft metals like aluminum or copper.

Is it necessary to wear protective gear when using a flush-cut saw?

Yes, wearing safety goggles and gloves is essential to protect yourself from potential injuries caused by flying debris or accidental slips during cutting.