Drill press tables are an essential component of any workshop, providing a stable and reliable platform for precise drilling operations. They are designed to enhance the functionality of your drill press, allowing for more accurate and efficient work. This article aims to provide an in-depth understanding of drill press tables, their importance, and factors to consider when purchasing one.

Understanding the intricacies of drill press tables is vital for anyone involved in woodworking or metalworking. It not only enhances your drilling accuracy but also ensures safety during operations. This guide will delve into the various features, types, and brands of drill press tables, providing valuable insights to help you make an informed purchase decision.

Furthermore, this guide will also explore the importance of maintenance and safety precautions when using drill press tables. It is crucial to understand these aspects to prolong the lifespan of your table and ensure a safe working environment. Let’s delve into the world of drill press tables.

Our Top Drill Press Tables Picks

WEN DPA2513 24-by-12-Inch Drill Press Table

Check on Amazon

Key Specs

- Dimensions: 23-7/8 x 11-7/8 x 1 inches

- Adjustable fence and stop block

- Includes three mounting clamps and two material hold-downs

- Compatible with WEN Drill Press series

- Onboard rulers for accurate measurements

The WEN DPA2513 24-by-12-Inch Drill Press Table is designed to expand your drilling workspace, providing enhanced versatility and precision. Compatible with the entire WEN Drill Press series, the spacious table measures 23-7/8 x 11-7/8 x 1 inches, offering ample room for larger projects. Its unique design allows clearance for the drill press’s height adjustment crank, ensuring smooth operation. The adjustable fence and stop block, combined with onboard rulers, facilitate precise and uniform drilling.

WEN DPA2412T 24 in. x 12 in. Drill Press Table

Check on AmazonKey Specs:

- Dimensions: 23-7/8 x 11-7/8 x 1 inches

- Expands workspace by 275 square inches

- Fits drill presses with tables between 5 and 16 inches wide

- Compatible with the WEN Drill Press series

- Includes drill press table only

The WEN DPA2412T 24-inch x 12-inch Drill Press Table provides a spacious 275 square inches of additional workspace for your projects. Measuring 23-7/8 x 11-7/8 x 1 inches, this table is designed to fit drill presses with a table width between 5 and 16 inches, making it versatile and compatible with the entire WEN Drill Press series. It’s a perfect addition to expand your work area and improve the precision of your drilling tasks.

MLCS 9765 Drill Press Table

Check on AmazonKey Specs:

- Includes 2 T-tracks for added versatility

- Adjustable fence for secure and precise holding

- Improved design for better performance

- Ideal for woodworkers seeking precision

- Affordable yet high-quality construction

The MLCS 9765 Drill Press Table enhances your drill press with versatility and precision at an unbeatable price. Featuring two T-tracks and an adjustable fence, this table provides maximum holding power for accurate and stable drilling. Perfect for woodworkers looking to improve their drilling setups with a high-quality, affordable solution.

Infinity Cutting Tools Drill Press Table

Check on Amazon

Key Specs:

- Sturdy laminated construction for durability

- T-tracks for added stops and hold downs

- Fast and easy installation

- Compatible with aftermarket tables

- Dimensions: 24″ L x 16″ W x 1″ H

The Infinity Cutting Tools Drill Press Table is designed for durability and precision, featuring sturdy laminated surfaces for both top and bottom. It includes T-tracks for adding stops and hold downs, enhancing versatility. Installation is fast and easy, and the included fences are compatible with any aftermarket table, making it a great addition to any drill press setup.

Grizzly Industrial H7827 Universal Drill Press Table

Check on Amazon

Key Specs:

- Table dimensions: 23-3/4″ wide x 11-7/8″ deep

- 3-inch high fence and stop block

- T-slots for easy fence adjustment

- Includes two universal table clamps

- Fits all standard drill press tables

The Grizzly Industrial H7827 Universal Drill Press Table enhances your work precision with its 23-3/4-inch wide by 11-7/8-inch deep design. It features a 3-inch high fence and a stop block for added support and accuracy. The fence and stop block slide along T-slots for easy setup. This table fits all standard drill press tables and comes with two universal table clamps for secure attachment.

Understanding Drill Press Tables

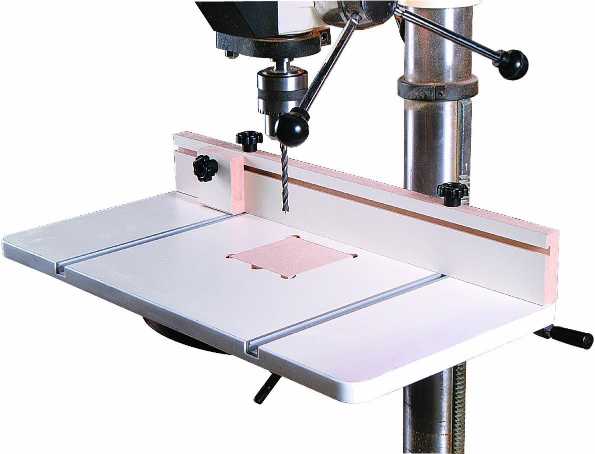

A drill press table is a flat surface attached to a drill press, providing a stable platform for drilling operations. It is typically equipped with features such as a fence for alignment, a stop block for repeated drilling operations, and clamping systems for securing the workpiece.

The primary function of a drill press table is to enhance the accuracy of drilling operations. It provides a stable and level surface, allowing for precise alignment and positioning of the workpiece. This is particularly important in woodworking and metalworking, where precision is paramount.

Moreover, a good drill press table can significantly improve the efficiency of your work. It allows for quick and easy setup, reduces the risk of errors, and enables repeated drilling operations with consistent results. In essence, a drill press table is a valuable tool that can elevate the quality and efficiency of your work.

Factors to Consider When Buying Drill Press Tables

When purchasing a drill press table, several factors need to be considered to ensure you choose the right one for your needs. The size and dimensions of the table are crucial, as they determine the size of the workpiece that can be accommodated. It’s important to choose a table that is large enough for your projects but not so large that it becomes cumbersome to use.

The material and durability of the table are also important considerations. Drill press tables are typically made from metal or wood, each with its own advantages and disadvantages. Metal tables are more durable and can withstand heavy-duty use, while wooden tables are lighter and easier to work with. The choice of material largely depends on the nature of your projects and personal preferences.

Another critical factor is the compatibility of the table with your drill press. Not all tables are compatible with all drill presses, so it’s important to check this before making a purchase. The table should fit securely on your drill press and be easy to install and remove.

Detailed Analysis of Drill Press Table Features

Drill press tables come with a variety of features designed to enhance your drilling operations. The surface area and workspace of the table are crucial, as they determine the size of the workpiece that can be accommodated. A larger surface area provides more workspace, allowing for larger projects and more flexibility in positioning the workpiece.

The fence and stop block system is another important feature. The fence provides a reference edge for aligning the workpiece, while the stop block allows for repeated drilling operations at the same location. These features greatly enhance the accuracy and efficiency of your work.

The insert system and replaceability of the table are also important considerations. The insert system allows for the use of different types of drill bits, while the replaceability of the table ensures that it can be easily replaced if it becomes damaged or worn out. These features contribute to the versatility and longevity of the drill press table.

Importance of Adjustable Features

Adjustable features are a key aspect of drill press tables, providing flexibility and precision in drilling operations. Adjustable height and angles allow for precise positioning of the workpiece, accommodating different sizes and shapes of materials. This is particularly important in woodworking and metalworking, where precision is paramount.

The importance of adjustable features extends beyond precision. They also contribute to the versatility of the drill press table, allowing it to be used for a wide range of projects. Whether you’re drilling holes in a large piece of wood or a small metal component, adjustable features ensure that your drill press table can handle the task.

Furthermore, adjustable features can enhance the efficiency of your work. They allow for quick and easy setup, reducing the time spent on preparing for drilling operations. In essence, adjustable features are a valuable asset that can significantly improve the functionality of your drill press table.

The Role of Clamping Systems

A secure clamping system is a crucial component of a drill press table. It ensures that the workpiece is firmly held in place during drilling operations, enhancing accuracy and safety. A good clamping system should be easy to use, provide a strong grip, and accommodate a wide range of workpiece sizes.

There are different types of clamping systems available, each with its own advantages and disadvantages. Some common types include T-slot clamps, which are versatile and easy to adjust; quick-release clamps, which allow for fast and easy setup; and vise clamps, which provide a strong grip for heavy-duty operations. The choice of clamping system largely depends on the nature of your projects and personal preferences.

Regardless of the type, a good clamping system is essential for any drill press table. It not only enhances the accuracy and efficiency of your work but also ensures safety during operations. Therefore, it’s important to consider the clamping system when purchasing a drill press table.

Importance of Dust Collection Ports

Dust collection ports play a crucial role in maintaining a clean workspace. They collect the dust and debris generated during drilling operations, preventing them from spreading around the workspace. This not only keeps your workspace clean but also protects your health by reducing exposure to dust and other harmful particles.

When considering dust collection systems, it’s important to consider the size and placement of the ports. They should be large enough to collect a significant amount of dust and conveniently located for easy access. Additionally, the system should be compatible with your dust collection equipment.

Furthermore, a good dust collection system can prolong the lifespan of your drill press table. By preventing dust and debris from accumulating on the table, it reduces wear and tear and keeps the table in good condition. Therefore, dust collection ports are an important feature to consider when purchasing a drill press table.

Understanding the Price Range

The cost of drill press tables can vary widely, depending on the size, material, features, and brand. On average, you can expect to pay anywhere from $50 to $500 for a drill press table. It’s important to set a budget before shopping and consider what features and quality you’re getting for the price.

Several factors can affect the price of a drill press table. High-quality materials and construction typically command a higher price, as do tables with advanced features such as adjustable height and angles, a robust clamping system, and a dust collection system. The brand can also influence the price, with well-known brands often charging more for their products.

While price is an important consideration, it should not be the only factor in your decision. It’s important to consider the value that the table offers in terms of quality, features, and longevity. A cheap table may save you money upfront, but it may not last as long or perform as well as a more expensive table.

Top Brands for Drill Press Tables

There are many brands that manufacture drill press tables, each offering its own unique features and benefits. Some of the top brands include WEN, Shop Fox, and Woodpeckers. These brands are known for their high-quality products, innovative features, and excellent customer service.

WEN is a popular brand that offers a range of drill press tables suitable for both hobbyists and professionals. Their tables are known for their sturdy construction, easy installation, and adjustable features. Shop Fox is another reputable brand, offering heavy-duty tables with robust clamping systems and large workspaces. Woodpeckers, on the other hand, is known for its premium tables with advanced features such as precision-machined fences and replaceable inserts.

When comparing these brands, it’s important to consider their features, prices, and customer reviews. Each brand has its strengths and weaknesses, and the best one for you depends on your specific needs and budget. Therefore, it’s important to do your research and choose a brand that offers the best value for your money.

User Reviews and Ratings

User reviews and ratings are a valuable resource when shopping for a drill press table. They provide firsthand information about the product’s performance, quality, and value, helping you make an informed purchase decision. It’s important to read multiple reviews to get a balanced view of the product.

However, it’s important to interpret and use reviews wisely. Not all reviews are created equal, and some may be biased or misleading. It’s important to look for reviews that provide detailed and objective information about the product. Additionally, consider the overall rating of the product and the number of reviews it has received. A product with a high rating and a large number of reviews is generally a good sign of quality.

Furthermore, reviews can also provide valuable insights into the product’s features, ease of installation, and compatibility with different drill presses. They can also highlight any potential issues or drawbacks of the product. Therefore, user reviews and ratings are an important tool in your decision-making process.

Maintenance and Care for Drill Press Tables

Maintaining your drill press table is crucial for its longevity and performance. Regular cleaning is essential to remove dust and debris that can accumulate on the table and affect its accuracy. It’s also important to check the table regularly for any signs of wear or damage and replace any worn-out parts promptly.

Another important aspect of maintenance is lubrication. The moving parts of the table, such as the clamping system and adjustable features, should be lubricated regularly to ensure smooth operation. It’s also important to keep the table dry to prevent rust and corrosion.

Regular maintenance not only prolongs the lifespan of your drill press table but also ensures its optimal performance. A well-maintained table provides accurate and efficient drilling operations, enhancing the quality of your work. Therefore, it’s important to take good care of your drill press table.

Safety Precautions When Using Drill Press Tables

Safety is paramount when using drill press tables. It’s important to look for safety features such as a robust clamping system, a non-slip surface, and a safety guard. These features ensure that the workpiece is securely held in place and protect you from flying debris.

Safe usage practices are also crucial for your safety. Always wear protective gear such as safety glasses and gloves when operating the drill press. Keep your hands away from the drill bit and never leave the drill press running unattended. It’s also important to keep your workspace clean and organized to prevent accidents.

Furthermore, it’s important to follow the manufacturer’s instructions for installation and use of the drill press table. Improper installation or misuse can lead to accidents and damage to the table. Therefore, safety should always be your top priority when using a drill press table.

Conclusion

Drill press tables are a valuable tool for any workshop, enhancing the accuracy and efficiency of drilling operations. This guide has provided an in-depth understanding of drill press tables, including their features, types, and brands. It has also highlighted the importance of maintenance and safety precautions when using these tables.

When purchasing a drill press table, it’s important to consider factors such as size, material, compatibility, and features. It’s also important to consider the price and brand, and to read user reviews and ratings. With the right drill press table, you can elevate the quality of your work and enjoy a safer and more efficient drilling experience.

Whether you’re a hobbyist or a professional, a good drill press table is a worthy investment. It not only enhances your drilling accuracy but also improves your efficiency and safety. So, take your time, do your research, and choose a drill press table that best suits your needs and budget.

Appendix

For additional resources or information related to drill press tables, consider visiting woodworking forums or blogs. These platforms often provide valuable insights and tips from experienced users. Additionally, YouTube tutorials can provide visual guides on how to use and maintain drill press tables effectively.

FAQ

What is a drill press table?

A drill press table is an attachment placed on a drill press to provide a stable surface for workpieces, allowing for more precise drilling and better control.

How do you use a drill press table?

Place the workpiece on the table, adjust its position, and lock it in place to ensure accurate drilling with the drill press.

What are the benefits of a drill press table?

It improves accuracy, stability, and safety by providing a flat, adjustable surface for drilling operations.

Can a drill press table be customized?

Yes, many drill press tables offer adjustable fences, miter slots, and additional accessories for enhanced functionality and precision.

Is a drill press table necessary?

While not essential, it greatly enhances the performance of a drill press by providing a stable and adjustable platform for accurate drilling.