Mastering the Art of Rafter Squares in Woodworking

Hey there, fellow woodworking enthusiast! Ever heard of a rafter square? No, it’s not a square that hangs out on your roof. A rafter square, also known as a carpenter’s square, is a versatile tool used in woodworking to measure and mark angles, make straight cuts, and assist in complex framing tasks. Understanding how to use a rafter square is crucial for any woodworking project, from building a simple shelf to crafting intricate furniture pieces.

Knowing your way around a rafter square can make a world of difference in the accuracy and efficiency of your woodworking endeavors. So, let’s dive into the world of rafter squares and unlock the secrets they hold for woodworking success!

Our Top Rafter Square Picks

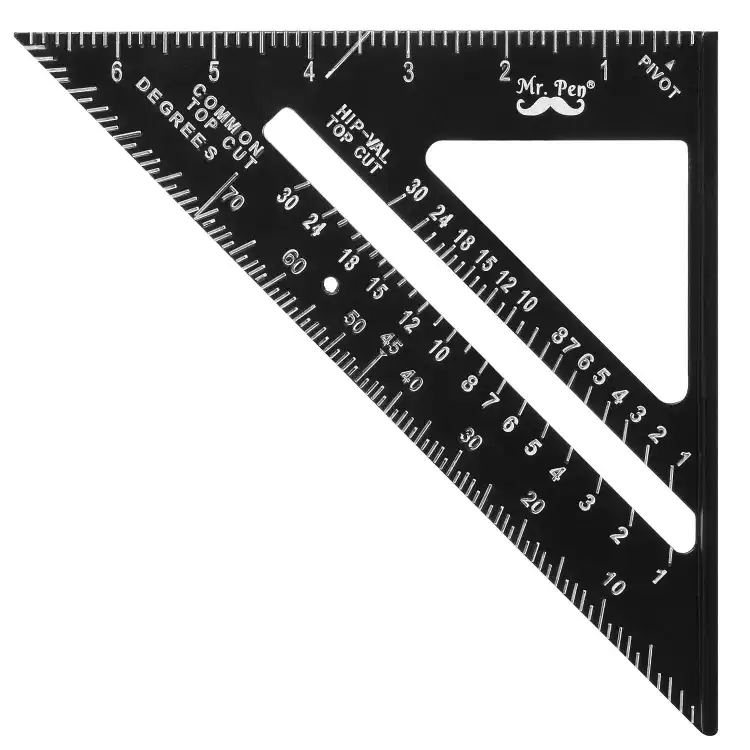

Mr. Pen- Rafter Square

Check on AmazonKey Specs:

- Material: Heavy-gauge billet aluminum alloy for accuracy and durability

- Compact design: 7-inch size fits easily in a pocket

- High-visibility markings: White gradations on a matte black finish for easy reading

- Multi-purpose functionality: Works as a protractor, saw guide, and rafter layout tool

- Precision markings: Gradations for common, hip, valley, and jack rafters

The Mr. Pen 7-inch Rafter Square is a compact yet highly precise tool designed for carpenters and woodworkers who demand accuracy. Made from heavy-gauge billet aluminum alloy, this die-cast square ensures durability and precision superior to extruded or stamped alternatives. The high-visibility white gradations on a non-glare matte black finish make measurements easy to read in any lighting. Whether marking common rafters, making square cuts, or setting angles, this tool is essential for efficiency in any woodworking project.

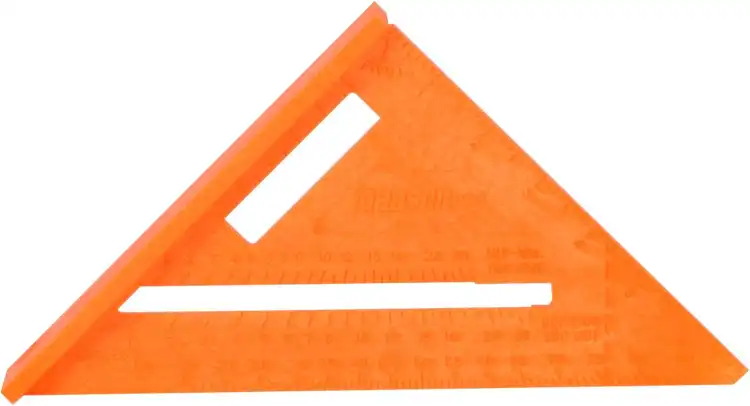

Johnson Level & Tool RAS-70B-ORAN Structo-Cast Rafter Square

Check on AmazonKey Specs:

- Material: High-grade plastic for durability and lightweight handling

- Graduation Markings: Molded-in scales for long-lasting readability

- Enhanced Visibility: Bright orange color for easy identification

- Versatile Use: Ideal for stair layout, rafter cuts, and saw guide applications

- Compact Size: Measures 7 x 5 inches for easy portability

The Johnson Level RAS-70B-ORAN Structo-Cast Rafter Square offers a durable yet lightweight design, making it an essential tool for carpenters. Crafted from high-grade plastic, it resists wear and tear while maintaining precision. The bright orange color ensures quick visibility in a crowded toolbox, while the permanently molded graduations allow for fast and accurate measurements. Designed for stair layout and rafter cuts, this square provides integrated angle scales and scribing notches for effortless marking, making it a reliable choice for framing and construction tasks.

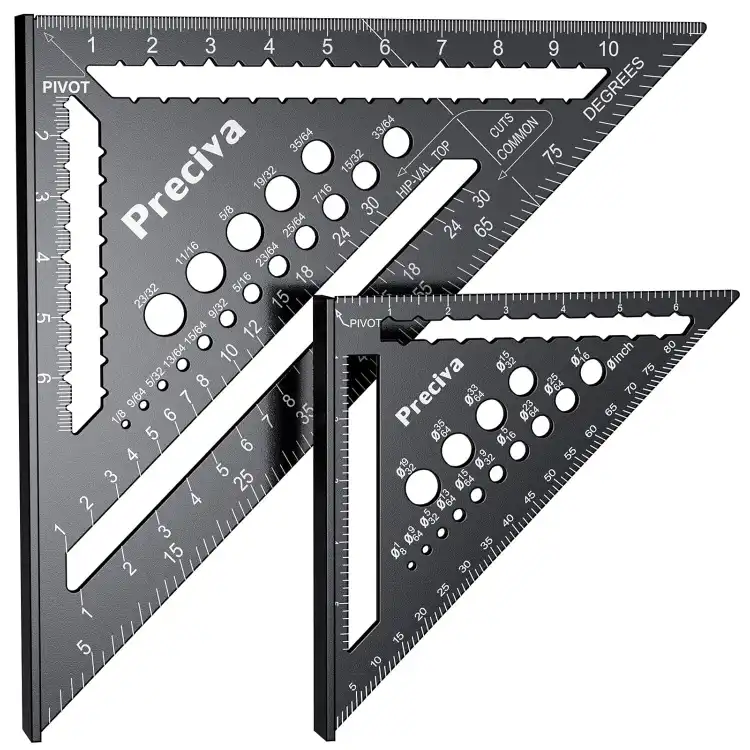

Preciva Carpenter Square Set, 12 inch (1/16″ Scale) and 7 inch Rafter Square Aluminum Alloy

Check on AmazonKey Specs:

- Material: Aluminum alloy for durability and scratch resistance

- Graduation Markings: 1/16-inch and 1/8-inch scales for enhanced precision

- Dual-Square Set: Includes both 12-inch and 7-inch speed squares

- Laser-Etched Markings: Clear, fade-resistant scale for long-term accuracy

- Versatile Application: Ideal for carpentry, construction, and DIY projects

The Preciva Carpenter Square Set provides unmatched accuracy with its laser-etched markings and 1/16-inch graduations, ensuring precise measurements for woodworking and construction. Crafted from durable aluminum alloy, this set resists scratches while maintaining long-term readability. The 12-inch and 7-inch squares allow for quick layout work, from angle marking to drilling positioning. Unlike standard rafter squares, its fine-scale calibration enhances precision, making it an essential tool for professionals who demand efficiency and accuracy in every project.

IRWIN Tools Rafter Square, Hi-Contrast Aluminum, Blue, 7-Inch

Check on AmazonKey Specs:

- Material: Rust-proof aluminum for long-lasting durability

- Markings: Deeply etched for permanent readability

- Measurement Accuracy: 1/16-inch graduation for precise layouts

- Multi-Purpose Use: Functions as a protractor, saw guide, and mitre square

- High-Contrast Finish: Blue coating enhances visibility in various lighting conditions

The IRWIN 7-Inch Rafter Square stands out with its high-contrast blue aluminum body, making measurements easy to read in any lighting condition. Designed for durability, its rust-proof aluminum construction ensures longevity even in tough job site conditions. The deeply etched markings remain visible over time, providing reliable precision. This multi-functional tool serves as a protractor, saw guide, and mitre square, allowing for seamless transitions between tasks. Its rugged build and accuracy make it a must-have for carpentry and framing professionals.

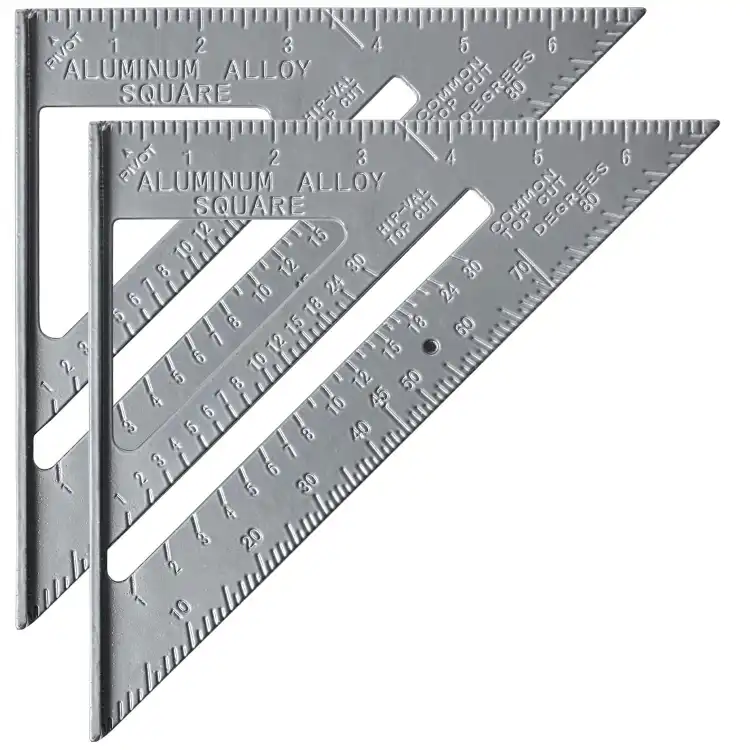

Mr. Pen Metal 7 Inches Rafter Square, Carpenter Square, 2 Pack

Check on AmazonKey Specs:

- Material: Rust-proof, weather-resistant aluminum alloy

- Graduation Range: 1/8-inch markings for precise measurements

- Multi-Purpose: Functions as a marking square, protractor, and saw guide

- Design: Clear, plain graduations for easy readability

- Set of Two: Ideal for professionals needing a backup or multi-station use

This Mr. Pen 7-Inch Rafter Square set offers precision and durability in a lightweight, rust-proof aluminum design. The clear, easy-to-read graduations ensure accuracy for layout, marking, and angle cuts. Whether you’re a carpenter, roofer, or builder, this square simplifies complex measurements, from finding roof pitch to guiding saw cuts. The sturdy aluminum alloy resists wear, making it a long-lasting addition to any toolbox. With two squares included, efficiency and convenience are doubled for any woodworking or construction task.

History of Rafter Squares

The humble rafter square has been a staple in the toolbox of carpenters and woodworkers for centuries. Its origins can be traced back to ancient civilizations where simple right-angle triangles were used for construction and woodworking tasks. Over time, these basic tools evolved into the more sophisticated rafter squares we use today.

Throughout history, rafter squares have undergone various design improvements to enhance their functionality and accuracy. From traditional wooden squares to modern aluminum or steel versions, the evolution of rafter squares reflects the continuous innovation in the field of woodworking tools.

| Period | Development |

|---|---|

| Ancient Times | Simple right-angle triangles used for basic measurements |

| Medieval Era | Introduction of more structured square designs |

| Industrial Revolution | Mass production of rafter squares with standardized markings |

Types of Rafter Squares

When it comes to rafter squares, there are various types to choose from based on your specific woodworking needs. The most common rafter square is the framing square, which features a long arm and a shorter tongue for making quick measurements and cuts. Additionally, there are specialized rafter squares like the speed square, which includes built-in features for roof framing and stair layout tasks.

For intricate woodworking projects that require precise angles and measurements, bevel squares and combination squares offer versatility and accuracy. These specialized rafter squares are essential for achieving complex cuts and joints with precision.

- Framing Square

- Speed Square

- Bevel Square

- Combination Square

Parts of a Rafter Square

Let’s break down the main components of a rafter square to understand how each part contributes to its functionality:

- Body: The main L-shaped body of the square provides a straight edge for marking and measuring.

- Tongue: The shorter arm perpendicular to the body, used for making 90-degree angles and quick measurements.

- Heel: The thicker end of the square that rests against the edge of the wood for stability.

- Fence: A lip along the body of the square that helps in holding it securely in place while marking or cutting.

How to Read a Rafter Square

Understanding the markings on a rafter square is key to utilizing its full potential in woodworking projects. The numbers and graduations on the square indicate various angles and measurements, allowing you to make precise cuts and joints. By interpreting these markings correctly, you can ensure the accuracy of your woodworking creations.

When using a rafter square, pay attention to the degree scale for angle measurements and the rafter tables for common roof pitches. Learning how to read these markings will empower you to tackle a wide range of woodworking tasks with confidence.

Basic Rafter Square Techniques

Ready to put your rafter square skills to the test? Here are some basic techniques to get you started:

- Finding Angles for Cuts: Use the degree scale on the rafter square to determine the angle for precise cuts.

- Making Square Cuts: Align the square against the edge of the wood to ensure perfectly square cuts every time.

Advanced Rafter Square Techniques

Once you’ve mastered the basics, you can explore more advanced techniques with your rafter square:

- Complex Roof Framing: Utilize the rafter tables and angle markings to tackle complex roof framing projects with accuracy.

- Creating Compound Angles: Combine multiple angle measurements on the rafter square to achieve intricate compound cuts for custom woodworking designs.

Common Mistakes to Avoid When Using a Rafter Square

While rafter squares are powerful tools, they can lead to errors if not used correctly. Here are some common mistakes to steer clear of:

- Misreading Measurements: Double-check the markings on the rafter square to avoid inaccurate cuts.

- Incorrectly Aligning the Square: Ensure the square is properly positioned against the wood to maintain precision in your cuts.

Benefits of Using a Rafter Square

Why bother mastering the art of rafter squares? Here are some compelling reasons:

- Accuracy in Measurements and Cuts: Rafter squares help you achieve precise angles and cuts for flawless woodworking results.

- Efficiency in Woodworking Projects: By using a rafter square, you can work faster and more efficiently, saving time and effort on your projects.

Practical Applications of Rafter Squares

Curious about how rafter squares come into play in real woodworking scenarios? Here are some practical applications:

- Building a Basic Wooden Structure: From simple frames to sturdy shelves, rafter squares are essential for constructing reliable wooden structures.

- Creating Custom Furniture Pieces: Designing and building custom furniture requires precise measurements and cuts, making rafter squares indispensable tools for the job.

Rafter Squares in Modern Construction

Even in the age of advanced technology, rafter squares continue to play a vital role in modern construction projects. Their versatility and accuracy make them indispensable tools for carpenters, contractors, and DIY enthusiasts alike.

By incorporating rafter squares into contemporary building practices, professionals can ensure the quality and precision of their work. From framing roofs to installing custom fixtures, rafter squares are trusted companions on the construction site.

Maintenance and Care of Rafter Squares

To keep your rafter square in top-notch condition, follow these maintenance tips:

- Cleaning: Regularly wipe down the square with a clean cloth to remove dirt and debris.

- Storing: Store the rafter square in a dry place to prevent rust and damage.

- Ensuring Accuracy: Check the square for any signs of wear or misalignment, and make adjustments as needed to maintain accuracy.

Comparison with Other Measuring Tools

While rafter squares are versatile tools, how do they stack up against other measuring instruments like tape measures? Let’s take a look:

| Rafter Square | Tape Measure |

|---|---|

| Provides precise angle measurements | Best for linear measurements |

| Ideal for complex cuts and framing tasks | Suitable for quick length measurements |

| Offers stability for marking and cutting | Portable and flexible for various applications |

Resources for Learning More About Rafter Squares

Ready to deepen your knowledge of rafter squares? Check out these resources for further education:

- Woodworking Tools

- Essential Woodworking Tools

- Plumbing Tools Guide

- Electrician Tools List

- Must-Have Automotive Tools

Conclusion

Congratulations on embarking on your rafter square journey! By understanding the ins and outs of this versatile tool, you’re well on your way to woodworking success. Remember, practice makes perfect, so don’t hesitate to experiment with different techniques and projects using your rafter square. Before you know it, you’ll be crafting masterpieces with precision and confidence!

FAQ

What is a rafter square used for?

A rafter square is primarily used in woodworking to measure and mark angles, make straight cuts, and assist in various framing tasks. Its versatility makes it an essential tool for carpenters and DIY enthusiasts alike.

How do I maintain my rafter square?

To keep your rafter square in optimal condition, regularly clean it with a cloth to remove dirt and debris. Store it in a dry place to prevent rust, and check for any signs of wear or misalignment to ensure accuracy.

Can rafter squares be used for complex woodworking projects?

Absolutely! Rafter squares are invaluable for complex woodworking projects that require precise angle measurements and cuts. With practice and a good understanding of the tool, you can tackle even the most intricate woodworking tasks with confidence.