Bar clamps, a staple in any craftsman’s toolbox, are versatile tools used in various projects. These clamps, known for their robustness and reliability, are essential for holding workpieces together during operations such as gluing, cutting, or drilling.

Whether you’re a professional woodworker, a metalworker, or a DIY enthusiast, bar clamps are indispensable. They provide stability and precision, ensuring that your projects are completed with the utmost accuracy and quality.

Understanding the functionality, types, and proper usage of bar clamps can significantly enhance your project outcomes. This article aims to provide a comprehensive guide on bar clamps, their importance in various projects, and factors to consider when purchasing them.

Our Top Bar Clamp Picks

Irwin Quick-Grip 1964758 One-Handed Mini Bar Clamps

Check on AmazonKey Specs:

- Clamping Force: 150 lbs.

- Material: Reinforced resin & hardened steel

- Size: 6-inch, 4-pack

- Non-Marring Pads: Prevents scratches

- Compact Design: 25% smaller for confined spaces

As a woodworking enthusiast, I appreciate the IRWIN QUICK-GRIP 1964758 Mini Bar Clamps for their reliable one-handed operation and firm yet non-marring grip. The reinforced resin body with hardened steel bars ensures durability, resisting flex under pressure. Despite their compact 6-inch size, they exert up to 150 lbs. of force, making them ideal for detailed clamping in tight spaces. The pistol-grip trigger provides effortless release, enhancing efficiency. These clamps are 25% smaller than standard models, offering precision without bulk.

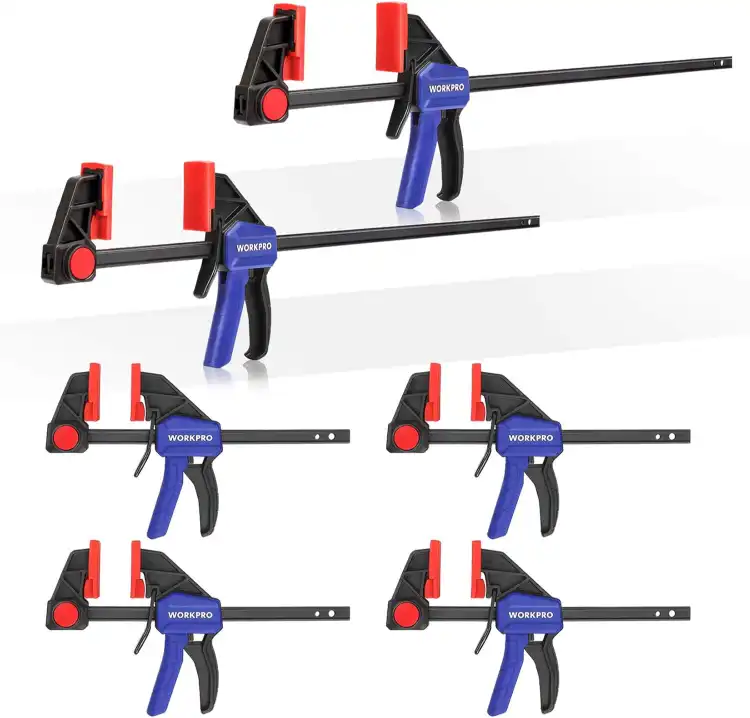

Workpro Bar Clamps

Check on AmazonKey Specs:

- Clamping Force: 150 lbs

- Material: Reinforced nylon & hardened steel

- Sizes Included: Four 6-inch, two 12-inch clamps

- Quick-Change Feature: Converts into spreaders

- Ergonomic Handle: Enhances comfort and control

The WORKPRO Woodworking Bar Clamps are a game-changer in my shop. Their reinforced nylon body ensures durability without excess weight, while the hardened steel bars resist flex under pressure. What sets them apart is the quick-change button, effortlessly converting them into spreaders—perfect for versatile applications. The ergonomic handle provides a comfortable grip, reducing hand fatigue during extended use. Plus, the non-marring, replaceable pads protect delicate surfaces. With four 6-inch and two 12-inch clamps, this set handles projects of all sizes.

Jorgensen Bar Clamp Set

Check on AmazonKey Specs:

- Clamping Force: 300 lbs

- Material: Solid steel construction

- Set Includes: Four F-style bar clamps

- Ergonomic Handle: Enhanced grip and comfort

- Distinctive Color: Orange & black for visibility

The Jorgensen Bar Clamp Set is a powerhouse in my workshop. With an impressive 300 lbs. load limit, these steel F-clamps provide superior holding strength for both woodworking and metalworking projects. Their ergonomic grip ensures a comfortable, slip-resistant hold, making prolonged use effortless. Unlike plastic-heavy alternatives, the solid steel construction delivers unmatched durability. The distinctive orange and black finish adds visibility in cluttered spaces. Whether I’m securing large panels or delicate pieces, these clamps offer the precision and reliability I need.

Wen Bar Clamps

Check on AmazonKey Specs:

- Clamping Force: 1200+ lbs

- Bar Length: 36 inches

- Throat Depth: 2.5 inches

- Quick-Adjust Mechanism: No button needed for sliding

- Micro-Adjustment Handle: Precision pressure control

The WEN Quick-Adjust 36-Inch Bar Clamps are an essential upgrade to my workshop. The quick-adjust mechanism eliminates the hassle of pressing a release button—just slide and clamp, saving time on every project. With a 1200+ lbs. clamping force, these clamps hold even the toughest materials securely. The micro-adjustment handle allows for fine-tuned pressure control, ensuring precision. A 2.5-inch throat depth provides ample reach, while the non-marring pads protect delicate surfaces. These clamps redefine efficiency and strength.

Horusdy Bar Clamps

Check on AmazonKey Specs:

- Clamping Force: 150 lbs

- Set Includes: 4x 6″ bar clamps, 2x 12″ bar clamps, 2x 6″ spring clamps

- Material: Nylon body & hardened steel bars

- Quick-Change Button: Converts to spreaders

- Non-Slip Pads: Protect work surfaces and enhance grip

The Horusdy Bar Clamps offer outstanding versatility for any woodworking or home repair project. This 8-piece set includes 6″ and 12″ bar clamps, along with spring clamps, covering all your clamping needs. The strong nylon body and hardened steel bars provide durability for heavy use, while the quick-change button easily transforms the clamps into spreaders. With up to 150 lbs of squeeze capacity and non-slip pads, these clamps provide a secure, precise hold, making them a reliable tool in my workshop.

Understanding Bar Clamps

Bar clamps, also known as “F-clamps” due to their shape, are tools used to hold or secure objects together to prevent movement or separation during work. They apply inward pressure to prevent the workpiece from moving, ensuring precision and accuracy in your projects.

There are various types of bar clamps available, each designed for specific tasks. Some common types include parallel bar clamps, pipe clamps, and quick-grip bar clamps. Parallel bar clamps are ideal for woodworking as they provide even pressure along the entire jaw length. Pipe clamps, on the other hand, are perfect for larger projects due to their adjustable length. Quick-grip bar clamps are known for their ease of use and are suitable for light-duty clamping needs.

A bar clamp consists of several key components: the bar, the fixed jaw, the adjustable jaw, and the handle. The bar is the length of the clamp, while the fixed and adjustable jaws are used to hold the workpiece. The handle is used to tighten or loosen the clamp.

Importance of Bar Clamps in Projects

In woodworking, bar clamps are essential for holding pieces of wood together while glue dries. They ensure that the wood pieces bond correctly and maintain their shape. Without bar clamps, it would be challenging to achieve the desired precision and stability in woodworking projects.

Bar clamps also play a crucial role in metalworking. They are used to hold metal pieces together during welding or drilling. By providing a secure grip, bar clamps prevent the metal pieces from moving, ensuring accurate and safe operations.

For DIY enthusiasts, bar clamps are a must-have. Whether you’re building a bookshelf, repairing furniture, or creating a custom piece, bar clamps can make the process easier and more efficient. They not only provide stability but also free up your hands, allowing you to focus on the task at hand.

Factors to Consider When Buying Bar Clamps

When purchasing bar clamps, it’s crucial to consider the size and capacity of the clamp. The clamp should be large enough to hold your workpiece securely. However, it shouldn’t be so large that it becomes unwieldy and difficult to use.

The material and durability of the clamp are also important considerations. Bar clamps are typically made of steel or aluminum. Steel clamps are more durable and can withstand higher pressure, making them suitable for heavy-duty tasks. Aluminum clamps, on the other hand, are lighter and easier to handle, making them ideal for light-duty tasks.

Other factors to consider include the clamping pressure, ease of use, adjustability, and price. The clamp should provide sufficient pressure to hold the workpiece securely. It should also be easy to use and adjust. Finally, the price of the clamp should provide value for money.

Top Bar Clamp Brands

Several brands are renowned for their high-quality bar clamps. These include Bessey, Irwin, and Jorgensen. Bessey is known for its durable and reliable clamps, while Irwin is popular for its innovative designs. Jorgensen, on the other hand, is famous for its wide range of clamps suitable for various tasks.

When comparing different brands, it’s essential to consider factors such as durability, ease of use, clamping pressure, and price. Reading reviews and seeking recommendations can also help you make an informed decision.

Remember, the best bar clamp for you depends on your specific needs and preferences. Therefore, it’s crucial to understand your requirements before making a purchase.

How to Use Bar Clamps Safely

When using bar clamps, safety should be your top priority. Always ensure that the clamp is securely fastened to prevent the workpiece from moving. Avoid over-tightening the clamp as it can damage the workpiece or the clamp itself.

Regular maintenance and proper storage of bar clamps can also enhance their lifespan and performance. Clean the clamps regularly to remove any dust or debris. When not in use, store them in a dry and cool place to prevent rusting.

Remember, safety comes first. Always follow the manufacturer’s instructions and use the right clamp for the task at hand.

Case Study: Successful Projects with Bar Clamps

Bar clamps have been instrumental in the success of numerous projects. For instance, in a furniture-making project, bar clamps were used to hold the pieces together while the glue dried. This ensured that the pieces bonded correctly and maintained their shape, resulting in a sturdy and durable piece of furniture.

In a metalworking project, bar clamps were used to hold the metal pieces together during welding. This provided a secure grip, preventing the pieces from moving and ensuring accurate and safe welding.

These examples highlight the importance of bar clamps in achieving successful project outcomes. They underscore the need for choosing the right clamp for the task and using it correctly and safely.

Conclusion

Bar clamps are versatile and essential tools in various projects. Understanding their functionality, types, and proper usage can significantly enhance your project outcomes. When purchasing bar clamps, consider factors such as size, material, clamping pressure, ease of use, and price.

Remember, the best bar clamp for you depends on your specific needs and preferences. Therefore, it’s crucial to understand your requirements before making a purchase. With the right bar clamp, you can ensure precision, stability, and quality in your projects.

Whether you’re a professional woodworker, a metalworker, or a DIY enthusiast, bar clamps can make your work easier and more efficient. So, invest in a good set of bar clamps and take your projects to the next level.

FAQs

What are bar clamps used for?

Bar clamps are used to hold or secure objects together to prevent movement or separation during work. They are commonly used in woodworking, metalworking, and DIY projects.

What are the different types of bar clamps?

Some common types of bar clamps include parallel bar clamps, pipe clamps, and quick-grip bar clamps.

How do I choose the right bar clamp?

When choosing a bar clamp, consider factors such as size, material, clamping pressure, ease of use, and price. Also, consider the specific needs of your project.