Definition of an Arbor Press

An arbor press is a versatile tool used in various industries for performing precision work. It is a small hand-operated press that is typically used for riveting, installing, configuring, and removing bearings and other press fit work. The tool is named after the arbor, a type of spindle upon which the tool’s lever turns.

Arbor presses are available in various sizes, from one ton to five tons, and even larger for industrial applications. The size of the press determines the amount of force it can exert. The design of an arbor press is simple, yet robust, making it a reliable tool for precision work.

Despite its simplicity, an arbor press is a powerful tool. It can deliver a significant amount of force with minimal effort from the user. This makes it an invaluable tool in many industries, including manufacturing, metalworking, and automotive repair.

Our Top Arbor Press Picks

HHIP 8600-0031 Heavy Duty Arbor Press

Check on AmazonKey Specifications:

- Capacity: 1/2 Ton

- Press Height: 10.24 inches

- Base Dimensions: 9.53″ L x 4.35″ W

- Anvil: 4-position steel anvil

- Weight: 9.45 kg

The HHIP 8600-0031 Heavy Duty Arbor Press is a compact powerhouse for precision pressing tasks. With a 1/2-ton capacity, it delivers consistent, smooth operation, making it perfect for pressing bearings, bushings, and sleeves. Its 4-position steel anvil offers versatile pressing, while the steel pinions ensure durability and ease of use. Ideal for small metalwork, riveting, and even jewelry fabrication, this arbor press is built for heavy-duty use but designed for smaller spaces. It’s a must-have for precise workshop operations.

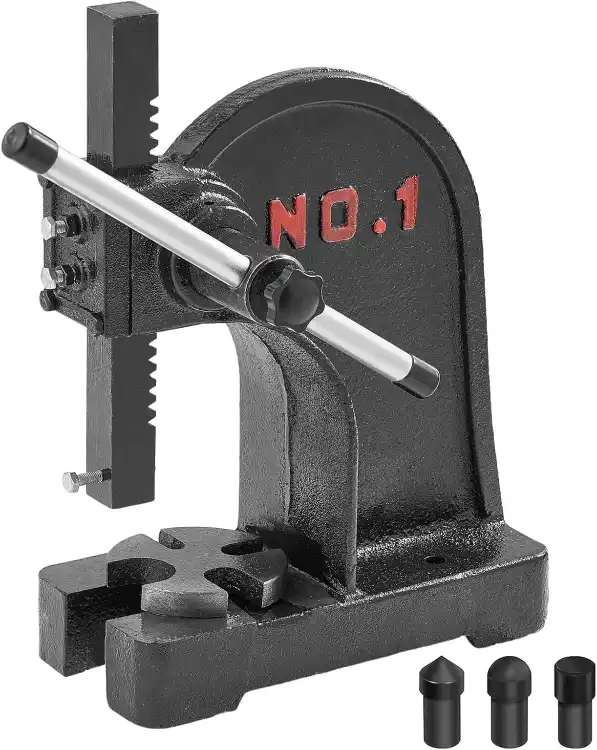

VEVOR 1 Ton Manual Arbor Press

Check on AmazonKey Specifications:

- Max Pressure Capacity: 1 Ton

- Max Working Stroke: 5.9 inches (150 mm)

- Ram Bore: 0.4 inches (10 mm)

- Plate Diameter: 3.5 inches (90 mm)

- Net Weight: 24.47 lbs (11.1 kg)

The VEVOR 1 Ton Manual Arbor Press is an exceptional tool for precise and efficient small-scale tasks. Its 1-ton capacity and 5.9-inch maximum working stroke offer reliable control for pressing, bending, and forming materials like metal and leather. The high-strength cast iron construction ensures long-lasting durability, while the adjustable labor-saving lever reduces strain during operation. The inclusion of three molds (flat, pointed, and round drift) allows versatility for various applications like riveting and stamping. This arbor press delivers excellent performance in both professional and DIY settings.

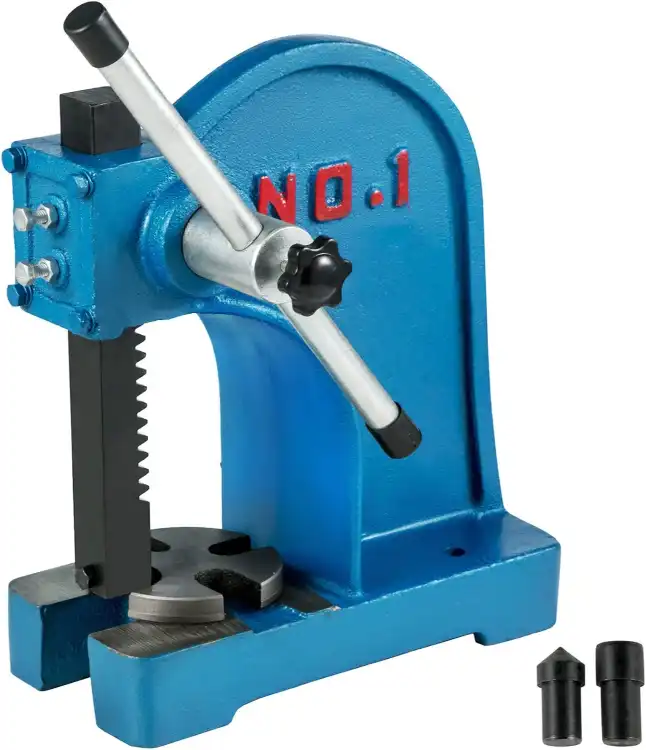

BestEquip Manual Arbor Press

Check on AmazonKey Specifications:

- Max Capacity: 1 Ton

- Max Work Height: 4.33 inches (110 mm)

- Ram Dimensions: 0.98 x 0.98 x 9.1 inches

- Plate Diameter: 3.54 inches (90 mm)

- Weight: 27 lbs (12 kg)

The BestEquip Manual Arbor Press offers a perfect balance of precision and power with its 1-ton capacity and 4.33-inch maximum work height. Made from high-quality cast iron, it provides exceptional durability for tougher tasks such as riveting, punching, and bending. The adjustable, non-slip lever makes operation easy and efficient, reducing fatigue. The slotted table plate allows versatility, and the solid base ensures stability. Whether you’re working with bearings or pressing small metal parts, this press is a valuable tool for various applications.

KAKA INDUSTRIAL AP-1/2, 0.5 Ton Steel Arbor Press

Check on AmazonKey Specifications:

- Capacity: 0.5 Ton

- Press Height: 11 inches

- Capacity Over Table: 3-3/4 inches

- Base Dimensions: 9-3/8″ length by 6-3/4″ width

- Weight: 15.33 lbs

The KAKA INDUSTRIAL AP-1/2 Arbor Press is a compact yet powerful tool designed for small-scale pressing tasks like riveting, punching, and fitting bearings. Its high-quality cast iron construction ensures durability, while the 4-position steel anvil allows for versatility in various applications. The 3-3/4″ capacity over the table and 11″ press height provide ample working space. It’s a reliable tool for precision pressing in mechanical or fabrication settings, making it ideal for small parts assembly or disassembly tasks.

PNBO 1 Ton Arbor Press

Check on AmazonKey Specifications:

- Capacity: 1 Ton

- Maximum Working Height: 5.5 inches

- Base Dimensions: 4.5″ L x 9.76″ W x 11.7″ H

- Anvil: Movable machined steel, adjustable slots

- Material: High-quality cast iron

The PNBO 1 Ton Arbor Press is a reliable, heavy-duty manual press perfect for precise tasks like riveting, bending, and punching. The ratcheted leverage system allows for controlled, consistent pressure application, while the movable machined steel anvil provides versatility for various workpiece sizes. Made of high-quality cast iron, this press ensures durability and stability during operation. The 5.5-inch maximum working height and adjustable anvil plate make it ideal for a variety of small to medium tasks in workshops or factories.

Importance of Precision Work

Precision work is crucial in many industries. It involves tasks that require a high level of accuracy and consistency. Without precision, products can have defects, machines can malfunction, and systems can fail. Therefore, having the right tools for precision work is essential.

An arbor press is one such tool. It allows for precise control over the force applied, making it ideal for tasks that require a delicate touch. Whether it’s installing a delicate component or removing a stubborn part, an arbor press can do the job with precision.

Moreover, precision work is not just about accuracy. It’s also about efficiency and productivity. A tool like an arbor press can speed up the work process, reduce errors, and improve the quality of the end product. This makes it a valuable asset in any precision work setting.

Understanding the Basics of an Arbor Press

Components of an Arbor Press

An arbor press consists of several key components. The most prominent is the lever or handle, which is used to apply force. The lever is connected to a pinion gear, which turns a rack and pinion system to generate force.

The press also includes a table or base where the workpiece is placed. The table can be adjusted vertically to accommodate different sizes of workpieces. Some arbor presses also include a gauge for measuring the force applied.

Despite its simple design, an arbor press is a complex tool. Each component plays a crucial role in its operation. Understanding these components and how they work together is key to using an arbor press effectively.

How an Arbor Press Works

The operation of an arbor press is straightforward. The user turns the lever, which rotates the pinion gear. The rotation of the gear moves the rack, which in turn moves the ram. The ram is the part of the press that applies force to the workpiece.

The force applied by the press can be adjusted by changing the position of the lever. This allows for precise control over the amount of force applied. The force is typically measured in tons, with larger presses capable of exerting more force.

One of the advantages of an arbor press is its mechanical advantage. Because of the way it’s designed, it can generate a significant amount of force with minimal effort from the user. This makes it an efficient tool for a wide range of tasks.

The Need for an Arbor Press in Precision Work

Role of Arbor Press in Precision Work

An arbor press plays a crucial role in precision work. It provides a controlled and consistent force, which is essential for tasks that require a high level of accuracy. Whether it’s installing a delicate component or removing a stubborn part, an arbor press can do the job with precision.

Moreover, an arbor press can be used for a wide range of tasks. It’s not just for pressing bearings and other press-fit work. It can also be used for riveting, stamping, bending, and other tasks. This versatility makes it a valuable tool in any precision work setting.

Finally, an arbor press is a reliable tool. It’s designed to withstand heavy use, and it’s simple to operate and maintain. This makes it a dependable tool for precision work, where reliability is key.

Benefits of Using an Arbor Press

There are several benefits to using an arbor press in precision work. First and foremost, it provides a high level of control over the force applied. This allows for precise, consistent results, which is crucial in precision work.

Second, an arbor press is versatile. It can be used for a wide range of tasks, from pressing bearings to riveting and stamping. This makes it a valuable tool in any workshop or manufacturing facility.

Finally, an arbor press is a reliable and durable tool. It’s designed to withstand heavy use, and it’s easy to maintain. This makes it a cost-effective solution for precision work, as it can last for many years with proper care.

Factors to Consider When Buying an Arbor Press

Determining the Right Size

When buying an arbor press, one of the first things to consider is the size. The size of the press determines the amount of force it can exert. Therefore, it’s important to choose a size that’s appropriate for the tasks you’ll be performing.

Arbor presses are available in various sizes, from one ton to five tons and even larger for industrial applications. A one-ton press is suitable for light-duty tasks, while a five-ton press is capable of handling heavier tasks. It’s important to choose a size that’s not only suitable for your current needs but also capable of handling any future tasks.

Another factor to consider is the size of the workpiece. The press should be large enough to accommodate the workpiece, but not so large that it’s unwieldy or difficult to use. Therefore, it’s important to consider both the size of the press and the size of the workpiece when making your decision.

Material and Build Quality

The material and build quality of the arbor press are also important factors to consider. The press should be made of durable materials that can withstand heavy use. The build quality should be high, with no loose or wobbly parts.

Most arbor presses are made of cast iron or steel, both of which are durable and robust materials. The press should also have a sturdy base that provides stability during use. A press with a weak or unstable base can be dangerous to use, as it can tip over or move unexpectedly.

Finally, the press should be well-constructed, with all parts fitting together snugly and securely. Any signs of poor construction, such as loose screws or uneven surfaces, should be a red flag. A well-constructed press will not only last longer but also perform better.

Load Capacity

The load capacity of the arbor press is another important factor to consider. This refers to the maximum amount of force the press can exert. The load capacity should be sufficient for the tasks you’ll be performing.

Load capacity is typically measured in tons. A one-ton press can exert a force of up to one ton, while a five-ton press can exert a force of up to five tons. It’s important to choose a press with a load capacity that’s suitable for your needs. A press with a too low load capacity may not be able to perform the tasks you need it to, while a press with a too high load capacity may be overkill.

It’s also worth noting that the actual force exerted by the press can vary depending on how the press is used. For example, using the press near the end of the lever will result in more force than using it near the base. Therefore, it’s important to understand how to use the press effectively to get the most out of its load capacity.

Ease of Use and Maintenance

Another factor to consider when buying an arbor press is ease of use and maintenance. The press should be easy to operate, with a smooth and responsive lever. It should also be easy to maintain, with accessible parts and a simple design.

Some arbor presses come with features that make them easier to use, such as a rotating base or a depth stop. These features can make the press more versatile and convenient to use. However, they can also add to the cost of the press, so it’s important to consider whether these features are worth the extra cost.

Maintenance is also an important consideration. The press should be easy to clean and lubricate, and any worn or damaged parts should be easy to replace. A press that’s difficult to maintain can become a hassle over time, so it’s worth considering this factor when making your decision.

Brand Reputation and Reviews

Finally, it’s worth considering the reputation of the brand and the reviews of the press. A reputable brand is more likely to produce a high-quality press, and positive reviews can provide reassurance about the quality and performance of the press.

When reading reviews, look for common themes. If many reviewers mention the same issues, such as poor build quality or difficulty in use, these could be red flags. On the other hand, if many reviewers praise the press for its durability and performance, this could be a good sign.

Remember, no press is perfect, and every press will have its pros and cons. The key is to find a press that meets your needs and has a good balance of quality, performance, and price.

Top Arbor Press Brands to Consider

Overview of Top Brands

There are several top brands to consider when buying an arbor press. These include Dake, Palmgren, and Jet. These brands are known for their high-quality products and excellent customer service.

Dake is a well-known brand in the industry, with a reputation for producing durable and reliable presses. Their presses are made of high-quality materials and are designed to withstand heavy use. They offer a wide range of sizes, from one ton to five tons, making them a versatile choice for any workshop or manufacturing facility.

Palmgren is another reputable brand, known for their innovative designs and high-performance products. Their presses are easy to use and maintain, with features such as a rotating base and a depth stop. They also offer a range of sizes, making them a flexible choice for any task.

Jet is a brand known for their robust and efficient presses. Their products are designed for heavy-duty use, with high load capacities and durable construction. They also offer a range of sizes, making them a suitable choice for a variety of tasks.

Comparison of Features and Prices

When comparing the features and prices of different arbor presses, it’s important to consider your specific needs. Some features, such as a rotating base or a depth stop, may be worth the extra cost if they make the press easier or more convenient to use. However, if these features are not necessary for your tasks, a simpler and cheaper press may be a better choice.

The price of an arbor press can vary widely, depending on the brand, size, and features. A small one-ton press can cost as little as $50, while a large five-ton press can cost several hundred dollars. It’s important to consider your budget when making your decision, but remember that a higher price often means higher quality and performance.

When comparing prices, it’s also worth considering the cost of maintenance and replacement parts. A cheaper press may end up costing more in the long run if it requires frequent maintenance or expensive replacement parts. Therefore, it’s worth considering the total cost of ownership, not just the initial purchase price.

How to Use an Arbor Press for Precision Work

Step-by-step Guide

Using an arbor press for precision work is straightforward. Here’s a step-by-step guide:

Prepare the press: Before using the press, make sure it’s clean and well-lubricated. Check all parts for wear or damage, and replace any worn or damaged parts as necessary.

Position the workpiece: Place the workpiece on the press table, making sure it’s properly aligned with the ram. Adjust the table height as necessary to accommodate the size of the workpiece.

Apply force: Turn the lever to apply force to the workpiece. Use the gauge to monitor the force applied, and adjust the lever position as necessary to control the force.

Release the force: Once the task is complete, release the force by turning the lever in the opposite direction. Remove the workpiece from the press table.

Clean and store the press: After using the press, clean it thoroughly and store it in a dry, clean place. Regular cleaning and proper storage can extend the life of the press and keep it in good working condition.

Safety Measures to Follow

When using an arbor press, it’s important to follow safety measures to prevent accidents or injuries. Here are some safety measures to follow:

Wear protective gear: Always wear protective gear when using the press, including safety glasses and gloves. This can protect you from flying debris or accidental contact with the press.

Use the press correctly: Always use the press as intended, and never exceed its load capacity. Using the press incorrectly or overloading it can cause damage to the press and potentially lead to accidents or injuries.

Keep the area clean: Keep the area around the press clean and free of clutter. This can prevent accidents caused by tripping or slipping.

Maintain the press: Regularly maintain the press to keep it in good working condition. This includes cleaning, lubricating, and replacing worn or damaged parts. A well-maintained press is not only more efficient but also safer to use.

Maintaining Your Arbor Press

Routine Maintenance Tips

Maintaining your arbor press is crucial for its performance and longevity. Here are some routine maintenance tips:

Clean the press: After each use, clean the press thoroughly to remove any dirt or debris. This can prevent wear and tear and keep the press in good working condition.

Lubricate the press: Regularly lubricate the press to reduce friction and prevent wear. Use a high-quality lubricant, and apply it to all moving parts.

Check for wear or damage: Regularly check the press for wear or damage. This includes checking the lever, pinion gear, rack, and ram for any signs of wear or damage. If any parts are worn or damaged, replace them as soon as possible.

Store the press properly: When not in use, store the press in a dry, clean place. This can prevent rust and other damage, and keep the press in good working condition.

Troubleshooting Common Issues

If you’re having issues with your arbor press, here are some common problems and how to troubleshoot them:

The press is not exerting enough force: If the press is not exerting enough force, it could be due to a lack of lubrication or a worn pinion gear. Try lubricating the press and checking the pinion gear for wear. If the gear is worn, replace it.

The press is difficult to operate: If the press is difficult to operate, it could be due to a lack of lubrication or a misaligned rack and pinion system. Try lubricating the press and checking the alignment of the rack and pinion system. If the system is misaligned, adjust it as necessary.

The press is unstable: If the press is unstable, it could be due to an uneven base or loose screws. Check the base for unevenness and tighten any loose screws. If the base is uneven, try placing a shim under it to level it.

Case Study: Successful Use of Arbor Press in Precision Work

Description of the Project

One successful example of using an arbor press in precision work is in the manufacturing of precision bearings. These bearings are used in various industries, including automotive, aerospace, and industrial machinery. They require a high level of precision and consistency, making an arbor press an ideal tool for their production.

The project involved pressing the bearings into their housings. This required a controlled and consistent force, which was provided by the arbor press. The press was also used to remove the bearings for maintenance or replacement.

The project was a success, with the arbor press providing the necessary precision and consistency. The bearings were installed accurately and securely, resulting in high-quality products and satisfied customers.

Role of the Arbor Press in the Project’s Success

The arbor press played a crucial role in the project’s success. It provided a controlled and consistent force, which was essential for the accurate installation of the bearings. Without the press, it would have been difficult to achieve the necessary level of precision and consistency.

The press also sped up the production process, as it was faster and more efficient than other methods. This increased productivity, allowing for more bearings to be produced in less time. This not only improved the bottom line but also increased customer satisfaction.

Finally, the press was reliable and easy to use, reducing the risk of errors or accidents. This made the production process smoother and safer, contributing to the overall success of the project.

Conclusion

Recap of Arbor Press Buying Guide

In conclusion, an arbor press is a versatile and reliable tool for precision work. When buying an arbor press, it’s important to consider factors such as size, material and build quality, load capacity, ease of use and maintenance, and brand reputation and reviews. Top brands to consider include Dake, Palmgren, and Jet.

Using an arbor press for precision work involves preparing the press, positioning the workpiece, applying force, releasing the force, and cleaning and storing the press. Safety measures to follow include wearing protective gear, using the press correctly, keeping the area clean, and maintaining the press.

Maintaining your arbor press involves cleaning the press, lubricating it, checking for wear or damage, and storing it properly. If you’re having issues with your press, common problems and solutions include not exerting enough force, difficulty in operation, and instability.

Emphasizing the Importance of Arbor Press in Precision Work

The importance of an arbor press in precision work cannot be overstated. It provides a controlled and consistent force, which is essential for tasks that require a high level of accuracy. It’s also versatile, reliable, and easy to use, making it a valuable tool in any precision work setting.

Whether you’re manufacturing precision bearings, installing delicate components, or removing stubborn parts, an arbor press can do the job with precision. With the right press and proper use and maintenance, you can achieve high-quality results, increase productivity, and improve safety in your precision work.

FAQs

What is an arbor press used for?

An arbor press is used for various tasks that require a controlled and consistent force, such as pressing bearings, installing and removing components, riveting, stamping, and bending.

How do I choose the right size arbor press?

Choose a size that’s appropriate for the tasks you’ll be performing and the size of the workpiece. Consider both the size of the press and the size of the workpiece when making your decision.

How do I maintain my arbor press?

Maintain your arbor press by cleaning it after each use, lubricating it regularly, checking for wear or damage, and storing it in a dry, clean place.

What safety measures should I follow when using an arbor press?

Wear protective gear, use the press correctly, keep the area clean, and maintain the press regularly to prevent accidents or injuries.

What are some top brands of arbor presses?

Some top brands of arbor presses include Dake, Palmgren, and Jet. These brands are known for their high-quality products and excellent customer service.