Brief Overview of Silicone Sprays

Silicone sprays are versatile products that have found their way into various industries due to their unique properties. They are made from silicone, a synthetic material known for its stability, heat resistance, and water-repelling capabilities. Silicone sprays are typically used as lubricants, protectants, and release agents, providing a thin, durable layer that can withstand high temperatures and harsh conditions.

These sprays are available in various forms, including aerosols and pump sprays, and can be used on a wide range of materials. They are particularly popular in the automotive industry, where they are used to lubricate and protect various parts. However, their uses extend far beyond this, with applications in home maintenance, industrial processes, and more.

Despite their widespread use, many people are unaware of the benefits and potential applications of silicone sprays. This article aims to shed light on these versatile products, discussing their composition, uses, benefits, and more.

Our Top Toto Toilet Picks

Ambro-Sol – OL103 Silicone Spray

Check on AmazonKey Specs

- Viscosity: 350–400 mm²/s at 77°F

- Flash Point: Below 32°F

- Self-Ignition Temp: >4032°F

- Vapor Pressure: <0.01 kPa at 68°F

- Water Solubility: Insoluble

The Ambro-Sol OL103 Silicone Spray is a pure silicone oil-based solution designed for serious maintenance tasks where high-performance lubrication and anti-adhesive properties are required. What makes this stand out is its multi-functional use—from enhancing gasket longevity to polishing plastic and providing water repellency across materials. I especially value its anti-static effect, which is a game-changer for delicate components. Plus, it’s Made in Italy, ensuring tight quality control and a formulation free from ozone-harming CFCs.

Cyclo Silicone Spray

Check on AmazonKey Specs:

- Silicone Content: 200% more than leading competitor

- Volume: 295.74 milliliters

- Weight: 284 grams

- Functions: Lubricates, seals, and protects

- Best Use: Prevents freezing/sticking in moving parts

The Cyclo Silicone Spray packs a serious punch with 200% more silicone than leading competitors, making it a high-performance option for anyone needing long-lasting lubrication and protection. I like using this for its multi-surface versatility—it’s great at sealing out moisture and preventing mechanisms from sticking or freezing, especially in harsh weather. Its clean application makes it ideal for rubber, plastic, and even leather, ensuring materials stay flexible and protected without residue buildup.

CRL PR03 Silicone Spray

Check on AmazonKey Specs:

- Multi-Purpose Lubrication: Effective on glass doors, drawers, windows, and hinges.

- Water Repellency: Keeps moisture out to prevent rust and corrosion.

- Quick-Drying: Dries fast without leaving residue, keeping surfaces clean.

- Non-Conductive: Safe for use near electrical components, reducing the risk of short circuits.

- Durability: Offers long-lasting protection with a high-quality silicone formula.

The CRL PR03 Silicone Spray is a high-performance silicone-based lubricant and moisture repellent designed to enhance the functionality and longevity of various mechanical components. Ideal for use on glass door rollers, windows, hinges, and other moving mechanisms, this spray provides a smooth, protective layer while repelling moisture and preventing rust and corrosion. It is perfect for applications where cleanliness and non-conductivity are important, making it safe for use around electrical components.

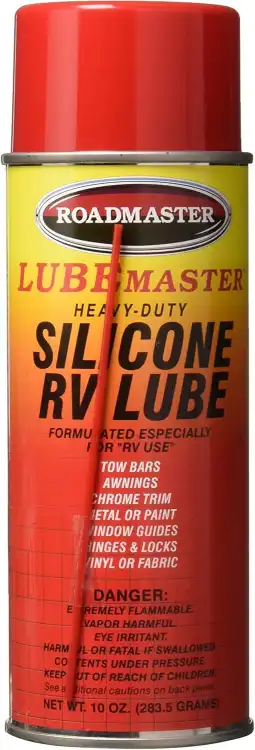

Roadmaster 747 LubeMaster Silicone Spray

Check on AmazonKey Specs:

- Versatile Lubrication: Perfect for a variety of uses, including tow bars, awning arms, and window tracks.

- Dry Silicone Formula: Leaves a clean, non-greasy finish, preventing dirt and debris buildup.

- Prevents Friction & Wear: Keeps moving parts operating smoothly and efficiently.

- Long-Lasting Protection: Ensures durable performance for equipment exposed to outdoor elements.

- Easy Application: Comes in an easy-to-use spray bottle.

The Roadmaster 747 LubeMaster Silicone Spray is a versatile, high-performance lubricant designed for a wide range of applications, particularly in the RV industry. This dry silicone spray provides smooth lubrication for tow bars, awning arms, window tracks, folding steps, and numerous other components. It helps to prevent friction and wear while ensuring easy operation of moving parts. Ideal for both indoor and outdoor use, it keeps equipment working smoothly without attracting dirt or dust.

Liquid Wrench M914 Silicone Spray

Check on AmazonKey Specs:

- Ultra-Slippery Lubrication: Reduces friction and enhances smooth operation.

- Water Repellent: Prevents moisture buildup, reducing the risk of rust and corrosion.

- Extends Equipment Life: Protects and extends the life of metal and non-metal surfaces.

- High Dielectric Strength: Safe for use on electrical components.

- Universal Fit: Suitable for a wide range of applications.

The Liquid Wrench M914 Silicone Spray is a premium lubricant designed to provide ultra-slippery lubrication for various applications. It repels water and inhibits rust, offering protection to both metal and non-metal surfaces, extending their lifespan. Its high dielectric strength ensures electrical safety, making it ideal for use on sensitive electrical components. This versatile silicone spray is perfect for preventing friction, squeaks, and corrosion in a wide range of tools and equipment.

Importance of Silicone Sprays in Various Applications

Silicone sprays play a crucial role in many applications due to their unique properties. They are highly resistant to heat, making them ideal for use in high-temperature environments. They also repel water, making them useful in wet conditions or for protecting items from moisture. Furthermore, they provide excellent lubrication, reducing friction and wear on moving parts.

These properties make silicone sprays invaluable in a wide range of industries. In the automotive industry, for example, they are used to lubricate and protect parts such as belts, cables, and hinges. In home maintenance, they can be used to lubricate door hinges, window tracks, and drawer slides, among other things. In industrial applications, they are used as release agents, helping to prevent materials from sticking to molds and other surfaces.

Despite their many uses, silicone sprays are often overlooked or misunderstood. By understanding their properties and potential applications, you can make the most of these versatile products.

Understanding Silicone Sprays

Definition and Composition of Silicone Sprays

Silicone sprays are products that contain silicone, a synthetic material known for its stability and resistance to extreme temperatures and conditions. The main component of these sprays is silicone oil, which is mixed with a solvent to create a thin, sprayable solution. The solvent evaporates after application, leaving behind a thin layer of silicone oil.

The exact composition of silicone sprays can vary depending on the specific product and its intended use. Some sprays may contain additional ingredients to enhance certain properties, such as increased heat resistance or improved lubrication. However, the primary function of all silicone sprays is to provide a protective, lubricating layer.

It’s important to note that while silicone sprays are generally safe to use, they should be used with care. They can be harmful if swallowed or inhaled, and they can cause eye irritation. Always follow the manufacturer’s instructions when using these products.

Different Types of Silicone Sprays

There are several types of silicone sprays available, each with its own unique properties and uses. The most common type is general-purpose silicone spray, which is designed for a wide range of applications. This type of spray is typically used as a lubricant or protectant, and it can be used on a variety of materials, including metal, plastic, rubber, and wood.

Another type of silicone spray is food-grade silicone spray, which is safe to use in food processing environments. This type of spray is often used as a release agent in food packaging and processing equipment, helping to prevent food from sticking to surfaces. It can also be used to lubricate food processing equipment, reducing wear and tear and extending the life of the equipment.

There are also specialty silicone sprays designed for specific applications. For example, high-temperature silicone sprays are designed to withstand extreme heat, making them ideal for use in automotive and industrial applications. Similarly, waterproof silicone sprays are designed to repel water, making them useful for protecting items from moisture and rust.

The Role of Silicone Sprays

Uses in Automotive Industry

Silicone sprays play a crucial role in the automotive industry, where they are used to lubricate and protect various parts. One of the most common uses is on rubber parts, such as belts and hoses, to prevent them from drying out and cracking. Silicone sprays can also be used on plastic parts to prevent them from becoming brittle and breaking.

Another common use of silicone sprays in the automotive industry is on electrical components. Silicone has excellent insulating properties, making it ideal for protecting electrical connections from moisture and corrosion. It can also be used to lubricate moving parts, such as hinges and cables, reducing friction and wear.

Despite their many uses in the automotive industry, it’s important to note that silicone sprays should be used with care. They can be harmful if swallowed or inhaled, and they can cause eye irritation. Always follow the manufacturer’s instructions when using these products.

Uses in Home Maintenance

Silicone sprays are also incredibly useful in home maintenance tasks. They can be used to lubricate door hinges, window tracks, and drawer slides, making them operate smoothly and quietly. They can also be used to protect outdoor items, such as garden tools and patio furniture, from rust and corrosion.

Another common use of silicone sprays in home maintenance is for waterproofing. By applying a thin layer of silicone spray to items such as boots, jackets, and tents, you can make them water-resistant, extending their life and improving their performance in wet conditions.

As with any product, it’s important to use silicone sprays responsibly. Always follow the manufacturer’s instructions, and avoid using them on surfaces where they could create a slip hazard, such as floors and stairs.

Uses in Industrial Applications

Silicone sprays are also widely used in industrial applications, thanks to their unique properties. One of the most common uses is as a release agent. By applying a thin layer of silicone spray to molds and other surfaces, manufacturers can prevent materials from sticking, making the production process smoother and more efficient.

Another common use of silicone sprays in industrial applications is for lubrication. They can be used to lubricate moving parts, reducing friction and wear and extending the life of the equipment. They can also be used to protect equipment from rust and corrosion, particularly in harsh or wet environments.

Despite their many benefits, it’s important to use silicone sprays responsibly in industrial applications. They can be harmful if swallowed or inhaled, and they can cause eye irritation. Always follow the manufacturer’s instructions, and ensure that adequate ventilation is provided when using these products.

Benefits of Using Silicone Sprays

Protective Properties

One of the main benefits of silicone sprays is their protective properties. When applied to a surface, they form a thin, durable layer that protects against moisture, heat, and wear. This makes them ideal for use on a wide range of materials, including metal, plastic, rubber, and wood.

For example, silicone sprays can be used to protect metal parts from rust and corrosion. By repelling water, they prevent moisture from coming into contact with the metal, reducing the risk of rust. They can also protect plastic and rubber parts from becoming brittle and cracking, extending their life and improving their performance.

Despite their protective properties, it’s important to note that silicone sprays are not a substitute for proper maintenance. They should be used as part of a regular maintenance routine, rather than as a quick fix for neglected or damaged items.

Smoothness and Lubrication Benefits

Another major benefit of silicone sprays is their lubrication properties. They reduce friction between moving parts, making them operate more smoothly and reducing wear and tear. This can extend the life of the parts and improve their performance.

For example, silicone sprays can be used to lubricate door hinges, window tracks, and drawer slides, making them operate more smoothly and quietly. They can also be used to lubricate moving parts in machinery and equipment, reducing friction and preventing wear.

Despite their lubrication benefits, it’s important to use silicone sprays responsibly. They can be harmful if swallowed or inhaled, and they can cause eye irritation. Always follow the manufacturer’s instructions, and avoid using them on surfaces where they could create a slip hazard, such as floors and stairs.

Longevity and Durability

Silicone sprays are also known for their longevity and durability. Once applied, they form a thin, durable layer that can withstand harsh conditions and high temperatures. This makes them ideal for use in a wide range of applications, from automotive and industrial to home maintenance.

For example, silicone sprays can be used to protect outdoor items, such as garden tools and patio furniture, from the elements. By repelling water and resisting heat, they can extend the life of these items and keep them looking their best.

Despite their longevity and durability, it’s important to note that silicone sprays are not a substitute for proper maintenance. They should be used as part of a regular maintenance routine, rather than as a quick fix for neglected or damaged items.

Factors to Consider When Buying Silicone Sprays

Type of Application

When buying silicone sprays, one of the first things to consider is the type of application. Different types of silicone sprays are designed for different uses, so it’s important to choose the right one for your needs.

For example, if you need a silicone spray for lubrication, you should look for a product that is specifically designed for this purpose. Similarly, if you need a silicone spray for protection against moisture and heat, you should look for a product that is designed to provide these benefits.

It’s also important to consider the materials you will be using the silicone spray on. Some silicone sprays are suitable for use on a wide range of materials, while others are designed for specific materials. Always check the manufacturer’s instructions to ensure that the product is suitable for your needs.

Brand Reputation

Another important factor to consider when buying silicone sprays is the brand’s reputation. There are many brands of silicone sprays on the market, and not all of them are created equal. Some brands are known for their high-quality products and excellent customer service, while others may have a reputation for poor quality or poor customer service.

Before buying a silicone spray, it’s a good idea to do some research on the brand. Look for reviews and testimonials from other customers, and check to see if the brand has any awards or certifications. This can give you a good idea of the quality of the product and the level of service you can expect from the brand.

It’s also worth considering the brand’s environmental and social responsibility. Some brands are committed to producing environmentally friendly products and giving back to their communities, which can be a deciding factor for some customers.

Price and Value for Money

Price is another important factor to consider when buying silicone sprays. While it’s tempting to go for the cheapest option, this isn’t always the best choice. Cheap silicone sprays may not provide the same level of protection or lubrication as more expensive products, and they may not last as long.

Instead of focusing solely on price, it’s a good idea to consider the value for money. This involves looking at the quality of the product, the amount of product you get for the price, and the benefits it provides. A high-quality silicone spray may cost more upfront, but it could save you money in the long run by reducing the need for repairs or replacements.

It’s also worth considering the cost of not using a silicone spray. Without the protection and lubrication provided by these products, your items may wear out more quickly, leading to costly repairs or replacements.

Top Silicone Spray Brands

Brief Overview of Top Brands

There are many brands of silicone sprays on the market, each with its own unique products and benefits. Some of the top brands include WD-40, 3M, and Permatex.

WD-40 is perhaps the most well-known brand of silicone spray. Their products are known for their high quality and versatility, and they are suitable for a wide range of applications. They offer a variety of silicone sprays, including general-purpose sprays, high-performance sprays, and specialty sprays for specific applications.

3M is another top brand of silicone spray. They offer a range of products designed for various applications, including lubrication, protection, and release. Their products are known for their high quality and durability, and they are trusted by professionals in a wide range of industries.

Permatex is a leading brand of automotive maintenance products, including silicone sprays. Their products are designed to provide superior protection and lubrication, and they are trusted by professionals in the automotive industry.

Comparison of Their Products

While all of these brands offer high-quality silicone sprays, there are some differences between their products. For example, WD-40’s silicone sprays are known for their versatility and can be used on a wide range of materials. They offer a variety of sprays, including general-purpose sprays and specialty sprays for specific applications.

3M’s silicone sprays are also highly versatile, but they are particularly known for their durability. Their products are designed to withstand harsh conditions and high temperatures, making them ideal for industrial applications. They also offer a range of specialty sprays for specific applications.

Permatex’s silicone sprays are specifically designed for automotive applications. They offer superior protection and lubrication for a wide range of automotive parts, and they are trusted by professionals in the industry.

Despite these differences, all of these brands offer high-quality products that can provide excellent protection and lubrication. The best brand for you will depend on your specific needs and preferences.

How to Use Silicone Sprays

Preparation Before Application

Before using a silicone spray, it’s important to prepare the surface properly. This usually involves cleaning the surface to remove any dirt, grease, or other contaminants. A clean surface will allow the silicone spray to adhere properly and provide the best protection and lubrication.

It’s also a good idea to protect any surrounding areas that you don’t want to spray. Silicone sprays can be difficult to remove from unwanted areas, so it’s best to prevent overspray by covering these areas or using a precision applicator.

Before applying the silicone spray, shake the can well to ensure that the ingredients are thoroughly mixed. This will help to ensure that you get the best performance from the product.

Proper Application Techniques

When applying a silicone spray, it’s important to use the correct technique. This usually involves spraying a thin, even layer onto the surface. Avoid spraying too much product at once, as this can lead to drips and runs and may not provide any additional benefits.

After spraying the product, allow it to dry for a few minutes. The solvent will evaporate, leaving behind a thin layer of silicone oil. This layer will provide protection and lubrication, and it should last for a long time under normal conditions.

It’s also important to reapply the silicone spray regularly, particularly in harsh conditions or high-wear areas. Regular reapplication will ensure that the surface remains protected and lubricated, extending the life of the item and improving its performance.

Safety Measures When Using Silicone Sprays

While silicone sprays are generally safe to use, it’s important to take some safety precautions. These products can be harmful if swallowed or inhaled, and they can cause eye irritation. Always use silicone sprays in a well-ventilated area, and avoid breathing in the spray. If you get the product in your eyes, rinse thoroughly with water.

It’s also important to keep silicone sprays out of reach of children and pets. These products can be harmful if swallowed, and the cans can be a choking hazard.

Finally, it’s important to store silicone sprays properly. They should be kept in a cool, dry place, away from heat sources and open flames. The cans are pressurized and can explode if exposed to high temperatures.

Common Mistakes When Using Silicone Sprays

Over-Application

One of the most common mistakes when using silicone sprays is over-application. Applying too much product at once can lead to drips and runs, and it may not provide any additional benefits. In fact, it can actually make the surface more slippery, which can be a hazard in some cases.

Instead of applying a lot of product at once, it’s better to apply a thin, even layer. This will provide sufficient protection and lubrication, and it will allow the product to dry properly. If necessary, you can apply a second layer after the first one has dried.

It’s also important to reapply the product regularly, particularly in high-wear areas or harsh conditions. Regular reapplication will ensure that the surface remains protected and lubricated, extending the life of the item and improving its performance.

Using on Inappropriate Materials

Another common mistake when using silicone sprays is using them on inappropriate materials. While silicone sprays are versatile and can be used on a wide range of materials, they are not suitable for all materials.

For example, silicone sprays should not be used on surfaces where they could create a slip hazard, such as floors and stairs. They should also not be used on certain types of plastic, as they can cause the plastic to become brittle and crack.

Before using a silicone spray, always check the manufacturer’s instructions to ensure that it is suitable for the material. If in doubt, test the product on a small, inconspicuous area first.

Ignoring Safety Precautions

Ignoring safety precautions is another common mistake when using silicone sprays. These products can be harmful if swallowed or inhaled, and they can cause eye irritation. It’s important to use them in a well-ventilated area, and to avoid breathing in the spray. If you get the product in your eyes, rinse thoroughly with water.

It’s also important to keep silicone sprays out of reach of children and pets. These products can be harmful if swallowed, and the cans can be a choking hazard.

Finally, it’s important to store silicone sprays properly. They should be kept in a cool, dry place, away from heat sources and open flames. The cans are pressurized and can explode if exposed to high temperatures.

Maintenance and Storage of Silicone Sprays

Proper Storage Conditions

Proper storage is crucial for maintaining the effectiveness of silicone sprays. These products should be stored in a cool, dry place, away from heat sources and open flames. The cans are pressurized and can explode if exposed to high temperatures.

It’s also important to keep the cans upright to prevent leakage. If the can is stored on its side or upside down, the product may leak out, wasting product and potentially causing a mess.

Finally, it’s important to keep the nozzle clean. After using the product, wipe off any excess product from the nozzle to prevent it from clogging. If the nozzle does become clogged, you can usually clear it by running it under warm water.

Shelf-Life and Expiration

Silicone sprays typically have a long shelf life, and they can be used for several years if stored properly. However, over time, the product may lose its effectiveness. If the product looks or smells different than usual, or if it doesn’t work as well as it used to, it may be time to replace it.

It’s also important to note that the shelf life of silicone sprays can be affected by storage conditions. If the product is stored in a hot or humid environment, it may not last as long. Always store silicone sprays in a cool, dry place to ensure that they last as long as possible.

Finally, it’s important to dispose of expired or unused silicone sprays properly. These products should not be thrown

FAQ

What is silicone spray?

Silicone spray is a lubricant and protective coating made from silicone that is used to reduce friction, prevent rust, and protect surfaces from moisture and wear.

How does silicone spray work?

It forms a thin, non-sticky layer on surfaces, reducing friction and preventing corrosion, while also repelling water and dust.

What are the benefits of using silicone spray?

It helps with lubrication, protects metal and rubber parts, reduces squeaks, and prevents rust, making it ideal for use on machinery, tools, and automotive parts.

Where can I use silicone spray?

Silicone spray can be used on a variety of surfaces, including metal, plastic, rubber, and wood, and is commonly used for door hinges, tools, sliding mechanisms, and weather stripping.

Is silicone spray safe to use on electronics?

Yes, many silicone sprays are safe for electronics, as they create a moisture-resistant coating without causing electrical conductivity. However, always check the product specifications for electronics compatibility.