Reciprocating saw blades are an essential tool in any handyman’s arsenal. They are versatile, powerful, and can make quick work of cutting through a variety of materials. The importance of these blades cannot be understated, as they can significantly impact the efficiency and quality of your work.

Choosing the right reciprocating saw blade is not just about picking the first one you see on the shelf. It requires a careful consideration of several factors, including the material you intend to cut, the type of saw you have, and how frequently you plan to use it. Making the right choice can mean the difference between a smooth, easy cut and a frustrating struggle.

The purpose of this article is to provide a comprehensive guide to understanding, choosing, and using reciprocating saw blades. We will delve into the different types of blades, their uses, and the factors to consider when buying one. We will also discuss the importance of proper maintenance and safety considerations to ensure that your blades last longer and work efficiently.

Our Top Reciprocating Saw Blade Picks

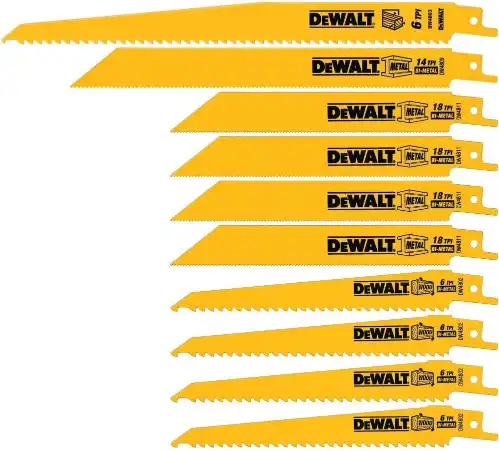

DEWALT Reciprocating Saw Blades

Check on AmazonKey Specs:

- Material: Bi-metal construction

- Blade Count: 10 pieces

- Compatible Materials: Wood, metal

- Case: Expandable, holds blades securely

- Length: Various sizes for multiple applications

The DEWALT Reciprocating Saw Blades (DW4898) are a must-have for anyone tackling a variety of cutting projects. This 10-piece set offers a versatile selection of blades, perfect for both wood and metal materials. The bi-metal construction is a standout, combining flexibility and durability for a longer-lasting edge. The blades come housed in a tough, expandable case, which keeps them organized and easily accessible. Whether you’re a professional or a DIYer, these blades will help you power through tasks with ease.

WORKPRO 32-Piece Reciprocating Saw Blade Set

Check on AmazonKey Specs:

- Blade Count: 32 reciprocating saw blades

- Material Compatibility: Wood, plastic, metal, drywall

- Clamp Set: 16-piece spring clamp set

- Clamp Capacity: Maximum opening of 1-3/8 inches

- Clamp Material: Reinforced nylon for durability

The WORKPRO 32-Piece Reciprocating Saw Blade Set & Spring Clamp Set offers incredible versatility for any project. The reciprocating saw blade set features a wide range of blades, making it ideal for cutting wood, plastic, metal, and drywall. The blades are compatible with all major reciprocating saw brands, ensuring flexibility in your tool collection. Paired with the WORKPRO Spring Clamp Set, which provides a sturdy grip with reinforced nylon construction, this kit ensures precision and durability in all your cutting and clamping tasks.

Milwaukee Electric Tool 49-22-1129 Sawzall Reciprocating Saw Blade Set

Check on AmazonKey Specs:

- Blade Count: 12 blades

- Compatible Materials: Wood, metal

- Blade Length: 12.75 inches

- Blade Width: 1 inch

- Blade Thickness: 0.06 inches

The Milwaukee Electric Tool 49-22-1129 Sawzall Reciprocating Saw Blade Set is designed for demolition professionals and DIYers who need reliable and durable cutting performance. This 12-piece set provides a selection of blades ideal for cutting through both wood and metal with precision. The blades feature strong metal construction, allowing for maximum durability, and their thin profile ensures clean cuts in tough materials. I appreciate how well these blades perform under heavy use, delivering high-speed results with minimal effort.

PORTER-CABLE Pruning Reciprocating Saw Blades

Check on AmazonKey Specs:

- Blade Length: 9 inches

- Teeth Count: 45

- Compatible Material: Wood

- Quantity: 3 blades per pack

- Color: Silver

The PORTER-CABLE Pruning Reciprocating Saw Blades (PC760R) are a great option for anyone who needs to tackle pruning tasks efficiently. With a 9-inch length and a sharp, durable construction, these blades effortlessly cut through wood, especially tree branches and shrubs. I particularly appreciate the precision and speed they offer, making pruning easier and faster. The 45 teeth provide a smooth cut, and the blend of materials ensures long-lasting performance, even under tough conditions.

DEWALT Reciprocating Saw Blades

Check on AmazonKey Specs:

- Material: Bi-Metal

- Teeth Count: 14 TPI

- Quantity: 6 blades per set

- Compatible Material: Wood, Metal

- Color: Multi

The DEWALT Reciprocating Saw Blades, Bi-Metal, 6-Piece Set (DW4896) stand out for their excellent versatility and durability. Whether you’re cutting through wood or metal, these bi-metal blades maintain their sharpness for a longer period, providing consistent performance. I love the variety in the set, which includes blades suitable for different applications. The 14 teeth per inch (TPI) design ensures smooth cuts, while the robust construction allows these blades to handle tough materials without bending or breaking.

Understanding Reciprocating Saw Blades

A reciprocating saw blade is a type of blade used in a reciprocating saw, a powerful tool that cuts by pushing and pulling the blade back and forth. The blade is the heart of the saw, and its design, material, and other features significantly impact its performance.

There are several types of reciprocating saw blades, each designed for a specific purpose. For instance, there are blades for cutting wood, metal, and even concrete. There are also demolition blades, pruning blades, and combination blades that can cut through multiple materials. Understanding the different types of blades and their uses is crucial in making the right choice for your needs.

Each type of reciprocating saw blade has unique features that make it suitable for a particular task. For example, wood-cutting blades typically have fewer, larger teeth to remove more material, while metal-cutting blades have more, smaller teeth for a smoother cut. Understanding these differences can help you choose the right blade for your project.

Importance of Choosing the Right Reciprocating Saw Blade

Choosing the right reciprocating saw blade is crucial for several reasons. First, it can significantly impact the efficiency of your cutting. A blade that is not suited for the material you are cutting can struggle, resulting in rough cuts and longer cutting times. On the other hand, a blade that is perfectly matched to your material can cut through it like butter, making your work easier and faster.

Second, the right blade can extend the lifespan of your saw. Using the wrong blade can put unnecessary strain on your saw, causing it to wear out faster. Conversely, the right blade can reduce the load on your saw, helping it last longer.

Finally, choosing the right blade can also affect the quality of your cuts. A blade that is not suited for your material can result in jagged, uneven cuts. In contrast, the right blade can produce clean, smooth cuts, improving the quality of your work.

Factors to Consider When Buying a Reciprocating Saw Blade

When buying a reciprocating saw blade, there are several factors to consider. The first is the material you intend to cut. Different blades are designed for different materials, so it’s important to choose a blade that is suited for your material. For example, if you’re cutting wood, you’ll want a blade with fewer, larger teeth, while if you’re cutting metal, you’ll want a blade with more, smaller teeth.

The type of saw you have is another important consideration. Not all blades are compatible with all saws, so you’ll need to make sure the blade you choose fits your saw. You’ll also want to consider the power of your saw, as some blades require more power to operate effectively.

Finally, you’ll want to consider how frequently you plan to use the blade. If you’re a professional contractor who uses your saw daily, you’ll want a durable, high-quality blade that can withstand heavy use. On the other hand, if you’re a DIY enthusiast who only uses your saw occasionally, you might be able to get by with a less expensive blade.

Understanding Blade Teeth

The teeth of a reciprocating saw blade play a crucial role in its cutting performance. The number of teeth per inch (TPI) can affect the speed and smoothness of the cut. Blades with fewer teeth (like those used for cutting wood) remove more material with each stroke, resulting in faster cuts. However, these cuts are usually rougher. Blades with more teeth (like those used for cutting metal) make slower, smoother cuts.

There are also different types of blade teeth, each designed for a specific purpose. For example, raker teeth are used for cutting wood and metal, while wavy teeth are used for cutting metal and plastic. Understanding the different types of teeth and their uses can help you choose the right blade for your project.

It’s also important to note that the size and shape of the teeth can affect the blade’s performance. Larger, more aggressive teeth can cut faster, but they may also cause more vibration and produce rougher cuts. Smaller, less aggressive teeth cut slower, but they produce smoother cuts and cause less vibration.

Material of the Blade

The material of the reciprocating saw blade is another important factor to consider. Most blades are made of high-speed steel (HSS), which is durable and resistant to heat. However, HSS blades can dull quickly when cutting harder materials.

Bi-metal blades are another common option. These blades combine a high-speed steel cutting edge with a flexible, durable body, offering a good balance of cutting performance and durability. They are more expensive than HSS blades, but they also last longer.

Carbide-tipped and diamond-grit blades are also available. These blades are extremely hard and durable, making them ideal for cutting tough materials like concrete and cast iron. However, they are also the most expensive type of blade.

Blade Length and Thickness

The length of the reciprocating saw blade can affect its cutting performance. Longer blades can reach deeper into the material, making them ideal for cutting through thick materials or making deep cuts. However, longer blades can also be more difficult to control, especially when making precise cuts.

The thickness of the blade is another important factor. Thicker blades are more durable and less likely to bend or break, making them ideal for heavy-duty cutting tasks. However, they can also be heavier and more difficult to maneuver, especially in tight spaces.

When choosing a blade length and thickness, it’s important to consider the nature of your cutting task. If you’re making deep cuts in thick materials, a longer, thicker blade may be the best choice. However, if you’re making precise cuts in tight spaces, a shorter, thinner blade may be more suitable.

Blade Coating

The coating on a reciprocating saw blade can play a significant role in its cutting performance. Some blades are coated with a special material to reduce friction, making them cut smoother and faster. This can also help extend the blade’s lifespan by reducing wear and tear.

There are several types of blade coatings, each with its own advantages and disadvantages. For example, black oxide coatings provide corrosion resistance and reduce friction, but they can wear off over time. Carbide coatings are extremely hard and durable, but they can also be expensive.

When choosing a blade coating, it’s important to consider the nature of your cutting task and the material you’re cutting. For example, if you’re cutting a material that is prone to causing friction, a blade with a friction-reducing coating may be the best choice.

Brand Considerations

When buying a reciprocating saw blade, it’s important to consider the brand. While there are many brands to choose from, not all of them offer the same quality and performance. Choosing a reputable brand can give you peace of mind that you’re getting a high-quality blade that will perform well and last long.

Some of the top brands to consider include Milwaukee, DeWalt, and Bosch. These brands are known for their high-quality blades that offer excellent cutting performance and durability. They also offer a wide range of blades to choose from, so you can find the perfect blade for your needs.

While brand is an important consideration, it’s not the only factor to consider. You should also consider the blade’s features, the material it’s made of, and the type of teeth it has. These factors can have a significant impact on the blade’s performance and lifespan.

Price vs. Quality

When buying a reciprocating saw blade, it’s important to strike a balance between price and quality. While it’s tempting to go for the cheapest blade, this can often be a false economy. Cheap blades can dull quickly, break easily, and deliver poor cutting performance, meaning you’ll have to replace them more often.

On the other hand, high-quality blades can offer excellent cutting performance and last much longer, making them a more cost-effective choice in the long run. While they may cost more upfront, they can save you money over time by reducing the need for replacements.

It’s also worth noting that the most expensive blade is not always the best choice. The best blade for you will depend on your specific needs, including the material you’re cutting, the type of saw you have, and how frequently you plan to use the blade.

Safety Considerations

Safety should always be a top priority when using reciprocating saw blades. These blades are powerful and can cause serious injury if not used properly. Therefore, it’s important to look for safety features when buying a blade.

Some blades come with safety features like anti-vibration handles, which can reduce the risk of hand fatigue and injury. Others have safety guards to protect you from flying debris. It’s also important to choose a blade that fits securely in your saw to prevent it from coming loose during use.

Safe usage of reciprocating saw blades also involves following proper safety procedures. This includes wearing protective gear like safety glasses and gloves, keeping your work area clean and well-lit, and maintaining a firm grip on the saw at all times.

Maintenance and Care of Reciprocating Saw Blades

Proper maintenance and care can extend the lifespan of your reciprocating saw blades and ensure they continue to deliver optimal cutting performance. One of the most important aspects of blade maintenance is keeping the blade sharp. Dull blades can strain your saw and deliver poor cutting performance, so it’s important to sharpen your blade regularly.

Proper storage is also crucial for maintaining your blade’s performance and lifespan. Blades should be stored in a dry, clean place to prevent rust and corrosion. They should also be stored in a way that protects the teeth from damage.

Cleaning your blade after each use can also help extend its lifespan. This involves removing any debris from the blade and applying a light coat of oil to prevent rust. It’s also important to inspect your blade regularly for signs of wear and tear and replace it if necessary.

Case Study: Successful Use of a Reciprocating Saw Blade

To illustrate the importance of choosing the right reciprocating saw blade, let’s consider a real-life example. A professional contractor was tasked with demolishing an old wooden deck to make way for a new one. He chose a high-quality, wood-cutting reciprocating saw blade for the job.

Thanks to the blade’s aggressive teeth and durable construction, the contractor was able to cut through the old wood quickly and efficiently. The blade also held up well to the heavy-duty cutting task, showing minimal signs of wear even after hours of use.

This case study highlights the importance of choosing the right blade for the job. By choosing a blade that was designed for cutting wood and could withstand heavy use, the contractor was able to complete the job quickly and efficiently, saving time and effort.

Common Mistakes to Avoid When Buying a Reciprocating Saw Blade

When buying a reciprocating saw blade, there are several common mistakes to avoid. One of the most common is choosing a blade based solely on price. While it’s important to consider cost, it’s also crucial to consider the blade’s quality and suitability for your needs. A cheap blade may save you money upfront, but it could cost you more in the long run if it dulls quickly or breaks easily.

Another common mistake is not considering the material you’ll be cutting. Different blades are designed for different materials, so it’s important to choose a blade that’s suited for your material. Using the wrong blade can result in poor cutting performance and damage to the blade.

Finally, many people make the mistake of not considering the type of saw they have. Not all blades are compatible with all saws, so it’s important to choose a blade that fits your saw. Using an incompatible blade can damage both the blade and the saw.

Conclusion

Choosing the right reciprocating saw blade is crucial for achieving efficient, high-quality cuts. By considering factors like the material you’re cutting, the type of saw you have, and how frequently you plan to use the blade, you can choose a blade that’s perfectly suited to your needs.

It’s also important to consider the blade’s features, such as the number and type of teeth, the material it’s made of, and any special coatings. These features can significantly impact the blade’s cutting performance and lifespan.

Finally, remember that safety should always be a top priority when using reciprocating saw blades. Always follow proper safety procedures and look for blades with safety features to reduce the risk of injury. With the right blade and proper usage, you can make the most of your reciprocating saw and achieve excellent cutting results.

FAQ

What is a reciprocating saw blade?

A reciprocating saw blade is a type of blade used in a reciprocating saw, a powerful tool that cuts by pushing and pulling the blade back and forth.

How do I choose the right reciprocating saw blade?

When choosing a reciprocating saw blade, consider factors like the material you’re cutting, the type of saw you have, how frequently you plan to use the blade, and the blade’s features.

How do I maintain my reciprocating saw blade?

To maintain your reciprocating saw blade, keep it sharp, store it properly, clean it after each use, and inspect it regularly for signs of wear and tear.