Brief overview of the importance of a hacksaw

The hacksaw, a tool often overlooked in its importance, is a fundamental instrument in any toolkit. Whether you’re a professional tradesperson or a DIY enthusiast, the hacksaw’s versatility and precision make it an indispensable tool. From cutting through metal and plastic to trimming wood, a hacksaw’s utility is vast and varied.

Despite its simple design, a hacksaw is a powerful tool. Its thin, sharp blade can cut through materials that would otherwise be challenging to work with. The hacksaw’s design allows for a high degree of control, enabling precise cuts and making it a preferred tool for detailed work.

Moreover, the hacksaw’s importance extends beyond its cutting capabilities. It’s a tool that encourages creativity, problem-solving, and practical skills. Whether you’re crafting a custom piece of furniture, repairing a bicycle, or installing a new pipe, a hacksaw can help you get the job done.

Our Top Hacksaw Picks

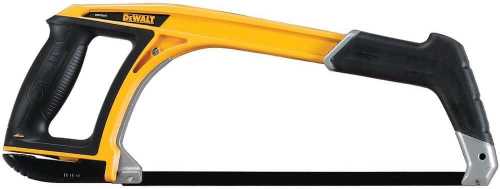

DEWALT Hack Saw

Check on AmazonKey Specs

- Sharp Tooth Induction Hardened Teeth: These teeth provide long-lasting durability, ensuring efficient cuts for an extended period.

- 8 Points for Fast and Aggressive Cuts: The saw is designed to make fast, aggressive cuts, helping you complete your projects more quickly.

- Comfortable Grip Handle: The plastic handle is ergonomically designed with a comfort grip, reducing hand fatigue during extended use.

- For Cutting Wood Quickly: This saw is ideal for cutting through wood, making it perfect for woodworking tasks.

The DEWALT Hack Saw is a high-quality tool designed for quick and efficient cutting. It features a comfortable and durable design, making it a reliable choice for cutting through wood and other materials.

CRAFTSMAN Hand Saw

Check on AmazonKey Specs:

- Blade Length: 12 inches

- Cutting Depth: 4.375 inches

- Tension Capacity: Up to 225 lbs

- Adjustable Blade Angles: 90° and 180°

- Comfortable Full-Grip Handle

The CRAFTSMAN Hand Saw is a versatile and reliable tool built for precision cutting. I particularly appreciate the solid metal frame that offers excellent blade security, handling tension up to 225 lbs. Its adjustable blade angles make flush cuts effortless, providing flexibility for various tasks. The comfortable tension knob and full-grip handle ensure optimal control and comfort during use. The high visibility bevel scale is also a thoughtful touch for accurate adjustments.

LENOX Tools Mini Hack Saw Frame

Check on AmazonKey Specs:

- Blade Length: 10 inches

- Teeth per Inch: 24

- Handle Material: Aluminum

- Blade Included: Yes (One blade)

- Application: Suitable for most metals, including stainless steel and un-hardened tool steel

The LENOX Tools Mini Hack Saw Frame is perfect for precise cutting in tight spaces. Its compact design and lightweight build make it ideal for restricted areas where larger tools can’t reach. The aluminum handle provides a sturdy grip, while the 24 teeth per inch blade ensures smooth, clean cuts through most metals, including stainless steel and un-hardened tool steel. With its 10-inch blade, it’s an efficient tool for detailed, smaller tasks.

Stanley High Tension-Low Profile Hacksaw

Check on AmazonKey Specs:

- Frame Material: Die-cast aluminum I-beam

- Cutting Angles: 45° and 90°

- Blade Tension: Adjustable with high-tension knob

- Handle: Ergonomically designed for comfort

- Warranty: Limited Lifetime Warranty

The Stanley High Tension-Low Profile Hacksaw stands out for its heavy-duty, lightweight die-cast aluminum I-beam frame, offering both strength and durability. The 45° and 90° cutting angles provide flexibility for various cuts, making it an adaptable tool for different tasks. The high-tension knob allows for easy blade tension adjustments, while the ergonomically designed handle ensures comfort during extended use. Plus, its patented design enhances both performance and ease of use.

LENOX Tools High-Tension Hacksaw

Check on AmazonKey Specs:

- Blade Tension: Up to 50,000 psi

- Handle: Rubberized for better grip

- Blade Storage: Holds up to 5 extra 12-inch blades

- Blade Compatibility: Accepts any LENOX reciprocating saw blade as a jab saw

- Included Blade: One 12-inch, 24 TPI blade

The LENOX Tools High-Tension Hacksaw is a high-performance tool designed for precision and durability. With an I-beam construction, it allows the blade to tension up to 50,000 psi, ensuring efficient and clean cuts. The rubberized handles provide a secure grip, even in wet or cold conditions, enhancing control. It also features a storage capacity for up to 5 extra 12-inch hacksaw blades, making blade replacement convenient. This model includes a 12-inch, 24 TPI blade, ready for immediate use.

Purpose of the article

This article aims to provide a comprehensive guide to understanding hacksaws. It will delve into the various types of hacksaws, their uses, and the importance of precision cutting power. It will also provide insights into factors to consider when buying a hacksaw, understanding hacksaw blades, and the role of Teeth Per Inch (TPI) in hacksaws.

Additionally, the article will discuss adjustable frames in hacksaws, the importance of comfortable handles, safety features, top hacksaw brands, and where to buy them. It will also provide tips on maintaining and caring for hacksaws and common mistakes to avoid when using them.

By the end of this article, you should have a thorough understanding of hacksaws, their importance, and how to choose and use them effectively. Whether you’re a seasoned professional or a beginner, this guide will provide valuable insights to enhance your toolkit and improve your craft.

Understanding Hacksaws

Definition and function of a hacksaw

A hacksaw is a versatile hand tool primarily used for cutting various materials such as metal, plastic, and wood. It consists of a frame that holds a blade under tension, a handle for grip, and often an adjustable mechanism to change the blade’s tension.

The primary function of a hacksaw is to cut through hard materials. Its thin, sharp blade allows for precise cuts, making it an ideal tool for detailed work. The blade’s teeth are designed to cut on the push stroke, meaning the cutting action occurs when you push the saw away from you.

While the hacksaw is primarily known for its cutting capabilities, it’s also used for other tasks. For instance, it can be used to notch materials, create grooves, or even shape objects. Its versatility makes it a valuable tool in various fields, including construction, plumbing, electrical work, and even arts and crafts.

Different types of hacksaws and their uses

There are several types of hacksaws, each designed for specific tasks. The most common type is the standard or regular hacksaw. This tool has a C-shaped frame that holds a blade under tension, and it’s used for cutting metal and plastic.

Another type is the junior hacksaw, which is smaller than the standard hacksaw and used for more delicate work. Its small size and fine blade make it ideal for precision cutting in tight spaces. The junior hacksaw is commonly used in model making, jewelry making, and other detailed work.

Then there’s the power hacksaw, an electrically powered version of the standard hacksaw. This tool is used for heavy-duty cutting tasks, such as cutting through thick metal pipes or bars. The power hacksaw can make quick work of tasks that would be time-consuming and labor-intensive with a manual hacksaw.

Importance of Precision Cutting Power

Explanation of precision cutting power

Precision cutting power refers to a tool’s ability to make accurate, clean cuts. It’s a measure of how effectively a tool can cut through a material without causing unnecessary damage or leaving rough edges. In the case of a hacksaw, precision cutting power is determined by factors such as the blade’s sharpness, the number of teeth per inch (TPI), and the user’s skill and technique.

A hacksaw with high precision cutting power can make clean, straight cuts through various materials. This precision is crucial for tasks that require a high degree of accuracy, such as creating joints in plumbing or crafting detailed pieces in woodworking.

Moreover, a hacksaw with high precision cutting power can also make the cutting process more efficient. It can cut through materials more quickly and with less effort, reducing the time and energy required for the task.

Importance of precision in various tasks

Precision is crucial in many tasks that involve a hacksaw. For instance, in plumbing, a hacksaw is often used to cut pipes to specific lengths. A precise cut is essential to ensure the pipe fits correctly and the plumbing system functions properly.

In woodworking, a hacksaw is used to create detailed pieces or intricate designs. Precision is key in these tasks to ensure the final product is aesthetically pleasing and structurally sound. A rough or uneven cut can ruin the appearance of a piece and potentially weaken its structure.

Even in tasks that don’t require a high degree of accuracy, precision is still important. A clean, straight cut is easier to work with and can make the subsequent steps of a project easier and more efficient. Therefore, regardless of the task at hand, precision cutting power is a valuable attribute in a hacksaw.

Factors to Consider When Buying a Hacksaw

Blade quality

The quality of a hacksaw’s blade is one of the most important factors to consider when buying this tool. A high-quality blade will be sharp, durable, and able to maintain its edge over time. It will also be resistant to rust and other forms of corrosion, ensuring it lasts longer and performs better.

When assessing blade quality, consider the material it’s made from. High-speed steel (HSS) blades are known for their durability and ability to cut through hard materials. Carbon steel blades, on the other hand, are more flexible and less likely to break, but they may not be as durable as HSS blades.

Also, consider the blade’s TPI (teeth per inch). A higher TPI will result in smoother cuts, while a lower TPI will cut faster but may leave a rougher finish. The right TPI for you will depend on the materials you’ll be cutting and the level of precision you require.

Handle comfort

The comfort of a hacksaw’s handle is another important factor to consider. A comfortable handle will make the tool easier to use and reduce the risk of hand fatigue or injury. It can also improve your control over the tool, leading to more precise cuts.

When assessing handle comfort, consider the material it’s made from. Rubber or plastic handles with a textured grip can provide a secure hold and reduce slippage. Also, consider the handle’s shape and size. It should fit comfortably in your hand and not cause any discomfort or strain when used for extended periods.

Some hacksaws also feature ergonomic designs that further enhance comfort and ease of use. These designs may include features like padded handles, curved shapes, or adjustable grips. While these features can increase the tool’s price, they can also make a significant difference in your user experience.

Frame strength and durability

The strength and durability of a hacksaw’s frame are also crucial factors to consider. A strong, durable frame will be able to withstand the pressure applied during cutting and last longer. It will also maintain the blade’s tension more effectively, leading to more precise cuts.

When assessing frame strength and durability, consider the material it’s made from. Steel frames are known for their strength and durability, but they can be heavy. Aluminum frames, on the other hand, are lighter and still reasonably strong, but they may not be as durable as steel frames.

Also, consider the frame’s design. A frame with a rigid, sturdy design will be more effective at maintaining blade tension and resisting bending or warping. Some frames also feature adjustable mechanisms that allow you to change the blade’s tension, providing more control and versatility.

Understanding Hacksaw Blades

Different types of blades and their uses

Hacksaw blades come in various types, each designed for specific tasks. The most common type is the regular or standard blade, which is used for cutting metal and plastic. This blade typically has a high TPI and is made from high-speed steel (HSS) for durability and cutting efficiency.

Another type is the raker blade, which has groups of teeth arranged in a specific pattern. This blade is used for cutting thicker materials, as the pattern of the teeth helps to clear away the material more effectively.

Then there’s the wavy blade, which has a wave-like pattern of teeth. This blade is used for cutting thin, delicate materials, as the wavy pattern of the teeth helps to prevent the material from tearing or chipping.

How to choose the right blade for your task

Choosing the right blade for your task is crucial to achieving the best results. The first step is to consider the material you’ll be cutting. Different materials require different types of blades. For instance, a standard blade is ideal for cutting metal and plastic, while a raker blade is better for cutting thicker materials.

Next, consider the level of precision you require. If you need to make smooth, precise cuts, choose a blade with a high TPI. If speed is more important than precision, a blade with a lower TPI may be more suitable.

Finally, consider the durability of the blade. If you’ll be using the hacksaw frequently or cutting through hard materials, choose a blade made from a durable material like high-speed steel. If you’ll be using the hacksaw less frequently or cutting through softer materials, a blade made from carbon steel may suffice.

The Role of Teeth Per Inch (TPI) in Hacksaws

Explanation of TPI

Teeth Per Inch (TPI) is a measure of the number of teeth on a hacksaw blade within a one-inch length. It’s a crucial factor that determines how a hacksaw cuts and the finish it leaves on the material. A higher TPI means more teeth are in contact with the material at any given time, resulting in smoother cuts. Conversely, a lower TPI means fewer teeth are in contact with the material, resulting in faster but rougher cuts.

The TPI of a hacksaw blade can range from as low as 14 to as high as 32. Blades with a TPI of 14 to 18 are considered coarse and are used for cutting soft materials like plastic and wood. Blades with a TPI of 24 to 32 are considered fine and are used for cutting hard materials like metal.

It’s important to note that the TPI is not the only factor that determines a hacksaw’s cutting performance. Other factors, such as the blade’s sharpness, the user’s skill and technique, and the material being cut, also play a role.

How TPI affects cutting precision and speed

The TPI of a hacksaw blade has a significant impact on its cutting precision and speed. A blade with a high TPI will cut more slowly but will leave a smoother finish on the material. This is because more teeth are in contact with the material at any given time, resulting in smaller, more precise cuts.

On the other hand, a blade with a low TPI will cut more quickly but will leave a rougher finish. This is because fewer teeth are in contact with the material, resulting in larger, less precise cuts. However, the increased speed can be beneficial for tasks that don’t require a high degree of precision or for cutting through soft materials that are easy to smooth out later.

Therefore, when choosing a hacksaw blade, it’s important to consider the trade-off between precision and speed. If you need to make precise cuts in hard materials, choose a blade with a high TPI. If speed is more important, or if you’re cutting through soft materials, a blade with a lower TPI may be more suitable.

Adjustable Frames in Hacksaws

Benefits of adjustable frames

Adjustable frames in hacksaws offer several benefits. One of the main advantages is the ability to change the blade’s tension. This allows you to adjust the hacksaw to suit different tasks and materials, providing more control and versatility.

Another benefit of adjustable frames is the ability to accommodate different blade lengths. This can be useful if you need to cut through large materials or make deep cuts. It also allows you to use the same hacksaw for a wider range of tasks, reducing the need for multiple tools.

Adjustable frames also tend to be more durable and robust. They’re typically made from strong materials like steel or aluminum and feature rigid designs that resist bending or warping. This ensures the frame can withstand the pressure applied during cutting and last longer.

How to adjust a hacksaw frame

Adjusting a hacksaw frame is a straightforward process. Most adjustable hacksaws have a mechanism, usually a screw or lever, that allows you to change the blade’s tension. To adjust the tension, you simply turn the screw or lever until the blade is as tight or loose as you want it to be.

To accommodate different blade lengths, some adjustable hacksaws have a movable end piece. This piece can be moved along the frame to fit blades of different lengths. To adjust the blade length, you simply loosen the end piece, move it to the desired position, and then tighten it again.

It’s important to note that when adjusting a hacksaw frame, you should always ensure the blade is properly tensioned and securely fitted. A loose or improperly fitted blade can lead to inaccurate cuts and can also be a safety hazard.

Importance of Comfortable Handles

Impact of handle design on user experience

The design of a hacksaw’s handle can have a significant impact on the user’s experience. A well-designed handle can make the tool easier to use, more comfortable to hold, and more effective at cutting.

A comfortable handle can reduce hand fatigue and strain, allowing you to use the hacksaw for longer periods. It can also improve your grip on the tool, providing better control and precision. Moreover, a comfortable handle can make the cutting process more enjoyable, encouraging you to use the tool more often and improve your skills.

On the other hand, a poorly designed handle can make the hacksaw difficult to use and uncomfortable to hold. It can cause hand fatigue and strain, reducing your ability to use the tool effectively. It can also lead to a poor grip, resulting in less control and precision.

Materials used in handle construction

The material used in a hacksaw’s handle can also affect its comfort and usability. Common materials include wood, plastic, and rubber.

Wooden handles are traditional and provide a warm, comfortable grip. However, they can be slippery when wet and may not be as durable as other materials.

Plastic handles are durable and easy to clean, but they can be hard and uncomfortable to hold for extended periods. Some plastic handles have a textured surface or rubber coating to improve grip and comfort.

Rubber handles provide a soft, comfortable grip and are resistant to slipping, even when wet. However, they can wear out over time and may need to be replaced.

Some hacksaws also feature ergonomic handles, which are designed to fit the shape of your hand and reduce strain. These handles can greatly enhance comfort and usability, especially for prolonged use.

Safety Features in Hacksaws

Essential safety features to look for

Safety is paramount when using any tool, and hacksaws are no exception. There are several safety features to look for when choosing a hacksaw.

One essential safety feature is a secure blade guard. This guard covers the blade when the hacksaw is not in use, protecting you from accidental cuts. Some blade guards are retractable, allowing you to expose the blade only when you’re ready to cut.

Another important safety feature is a non-slip handle. This handle provides a secure grip, reducing the risk of the hacksaw slipping out of your hand during use. Some non-slip handles also have a flared end to prevent your hand from sliding onto the blade.

Finally, consider a hacksaw with an adjustable blade tension. This feature allows you to control the blade’s tightness, reducing the risk of the blade snapping or slipping out of the frame during use.

Importance of safety when using hacksaws

Safety is crucial when using hacksaws. These tools have sharp blades that can cause serious injuries if not handled properly. Therefore, it’s important to use hacksaws with care and to follow safety guidelines.

Always wear protective gear, such as safety glasses and gloves, when using a hacksaw. Make sure the blade is securely fitted and properly tensioned before you start cutting. Use a steady, controlled motion to cut, and avoid forcing the hacksaw through the material.

Also, keep the hacksaw clean and well-maintained. A dirty or poorly maintained hacksaw can be more difficult to use and can increase the risk of accidents. Regularly check the blade for signs of wear or damage and replace it as needed.

Top Hacksaw Brands

Overview of leading hacksaw brands

There are several leading brands that produce high-quality hacksaws. These brands are known for their craftsmanship, innovation, and commitment to quality.

One of the top brands is Stanley. This company has been producing tools for over 170 years and is known for its durable, reliable products. Stanley’s hacksaws feature ergonomic designs, high-quality blades, and adjustable frames for versatility and ease of use.

Another leading brand is Bahco. This Swedish company is renowned for its innovative designs and high-performance tools. Bahco’s hacksaws feature comfortable handles, precision blades, and unique tensioning mechanisms for superior cutting power.

Other top brands include Lenox, known for its durable, high-speed steel blades; and DeWalt, known for its robust, heavy-duty tools. These brands offer a range of hacksaws to suit different needs and budgets.

Comparison of their key features

While all these brands produce high-quality hacksaws, they each have their unique features and strengths.

Stanley hacksaws, for instance, are known for their ergonomic designs. They feature comfortable handles and adjustable frames for ease of use. They also have high-quality blades that provide excellent cutting power.

Bahco hacksaws, on the other hand, are known for their innovative designs. They feature unique tensioning mechanisms that allow for precise blade tensioning. They also have comfortable handles and precision blades for superior cutting performance.

Lenox hacksaws are known for their durable, high-speed steel blades. These blades are designed to cut through hard materials with ease. Lenox hacksaws also feature comfortable handles and adjustable frames for versatility.

DeWalt hacksaws are known for their robust, heavy-duty designs. They feature strong frames and high-quality blades for heavy-duty cutting tasks. They also have comfortable handles and adjustable blade tension for ease of use.

Price Range and Where to Buy Hacksaws

Average price range of hacksaws

The price of hacksaws can vary widely depending on the brand, model, and features. On average, you can expect to pay between $10 and $50 for a good-quality hacksaw.

Basic hacksaws with few features can be found at the lower end of this price range. These hacksaws are suitable for occasional use or simple tasks. However, they may not be as durable or effective as more expensive models.

Mid-range hacksaws, which cost between $20 and $30, typically offer a good balance of quality and value. They often feature comfortable handles, adjustable frames, and high-quality blades. These hacksaws are suitable for regular use and a variety of tasks.

FAQ

What is a hacksaw?

A hacksaw is a hand tool used for cutting metal, plastic, and other materials, featuring a fine-toothed blade mounted in a frame.

How do you use a hacksaw?

Place the blade against the material, hold the saw firmly, and use a back-and-forth motion to cut through it.

What materials can a hacksaw cut?

A hacksaw is primarily used for cutting metal, but it can also cut plastic, PVC pipes, and sometimes wood with the right blade.

How do I change the blade on a hacksaw?

Loosen the frame, remove the old blade, place the new blade in the correct direction, and tighten the frame to secure it.

Is a hacksaw easy to use?

Yes, with a little practice, a hacksaw is straightforward to use for cutting materials accurately.