Brief Overview of Drawknives

Drawknives are traditional woodworking tools that have been in use for centuries. They are characterized by a long, flat blade with handles at both ends, designed to be pulled towards the user when in use. These tools are primarily used for shaping and smoothing wood, making them indispensable in carpentry and other woodworking crafts.

Despite the advent of modern power tools, drawknives continue to hold a special place in the hearts of woodworkers. Their simplicity, versatility, and the unique control they offer make them a preferred choice for many. The tactile connection between the craftsman and the material that drawknives provide is something that power tools often fail to replicate.

Whether you’re a seasoned woodworker or a beginner looking to expand your toolkit, understanding drawknives can significantly enhance your woodworking skills. This article aims to provide a comprehensive guide on drawknives, their uses, types, and factors to consider when purchasing one.

Our Top Drawknives Picks

BeaverCraft Draw Knife

Check on AmazonKey Specs

- Blade Material: High Carbon Steel

- Handle Material: Ashwood, Ergonomically Designed

- Blade Length: 4.3 Inches

- Item Length: 12.99 Inches

- Weight: 160 Grams

As a woodworker, I find the BeaverCraft Draw Knife to be an exceptional tool for carving and shaping wood. The high-carbon steel blade is impressively sharp right out of the box, effortlessly cutting through both softwoods and hardwoods. The ergonomic ashwood handles, finished with linseed oil, allow for long hours of comfortable use without hand fatigue. This tool is perfectly suited for detailed shaping, especially on wood without bark or knots, making it an indispensable carving companion.

Carmyra Draw Knife 8″ Straight Draw Shave Woodworking Tool

Check on AmazonKey Specs:

- Blade Length: 8 Inches

- Blade Thickness: 5mm

- Blade Angle: 30°

- Material: Hardened Steel (HRC 30)

- Includes: Rubber edge protector for safety

The Carmyra 8″ Straight Draw Knife is an outstanding tool for anyone looking to quickly and accurately remove wood and bark from logs or firewood. The 5mm thick, 30° angled blade ensures fast, precise shaving, ideal for shaping furniture, spindles, pegs, and more. Its hardened steel construction offers excellent durability, while the finely polished edge maintains sharpness for smooth operation. The wood grip handles provide comfort and secure control, making it a must-have for timber framers and woodworkers.

Stubai 9-1/2′ Drawknife

Check on AmazonKey Specs:

- Blade Length: 9-1/2 Inches

- Blade Width: 1 Inch

- Overall Length: 17 Inches

- Material: Alloy Steel (Heat Treated)

- Handle: Wood

The Stubai 9-1/2″ Drawknife is a high-quality tool crafted in Tyrol, Austria, known for its precision and reliability. With a 9-1/2″ blade and a subtle curve, this drawknife allows for exceptional control and accuracy when peeling or shaping wood. Its alloy steel blade is heat-treated to exacting standards, ensuring durability. The wooden handle provides a comfortable grip, while the lightweight, non-slip design enhances ease of use. Ideal for both professionals and enthusiasts.

Felled Draw Shave Knife

Check on AmazonKey Specs:

- Blade Length: 8 Inches

- Overall Length: 16.8 Inches

- Blade Width: 1.9 Inches

- Blade Thickness: 0.3 Inches

- Handle Material: Wood

The Felled 8″ Draw Shave Knife is an excellent tool for woodworking, especially for removing bark, shaping wood, and creating furniture. Its straight 8-inch blade made of hardened alloy steel ensures durability and precision, while the polished beveled edges make it easy to maintain sharpness. The dual wooden handles are ergonomically designed for comfort and control, allowing for smooth maneuverability. Perfect for timber framers, wood turners, and carvers, this drawknife excels in shaping spindles, bowls, and other wood projects.

Two Cherries 500-1320 225-Millimeter Drawknife

Check on AmazonKey Specs:

- Blade Length: 225 Millimeters

- Blade Material: High-Quality German Steel

- Blade Type: Straight

- Handle Material: Wood

- Recommended Uses: Carving, Shaping, Chair Making

The Two Cherries 500-1320 225-Millimeter Drawknife is an exceptional tool for woodworkers, offering both durability and versatility. With a straight blade, it allows for the removal of large amounts of wood quickly and efficiently. This drawknife is ideal for carvers, chair makers, shingle makers, and other craftsmen. Crafted from high-quality German steel, the blade maintains its sharpness for precision and longevity. The comfortable wooden handles provide a secure grip, making it easy to maneuver during long carving sessions.

Importance of Drawknives in Shaping Wood

Drawknives play a crucial role in shaping wood. They are used for debarking logs, shaping and fitting beams, and creating wooden furniture and sculptures. The ability to control the depth and angle of the cut gives the user the freedom to shape the wood as desired, making drawknives an essential tool for custom woodworking projects.

Moreover, drawknives are also used in making wooden utensils, bowls, and other curved objects. The unique design of the drawknife allows it to remove large shavings of wood, making it an excellent tool for quick and efficient material removal. However, with a skilled hand, drawknives can also be used for delicate, fine shaping work.

While power tools may speed up the process, they often lack the precision and control that drawknives offer. Hence, for projects that require a high level of detail and craftsmanship, drawknives are often the go-to tool.

Understanding Drawknives

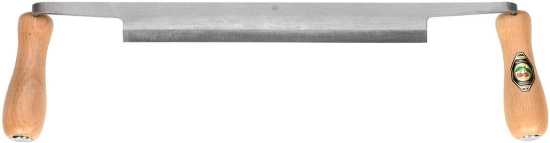

Definition and Description of Drawknives

A drawknife is a woodworking hand tool that consists of a blade with a handle at each end. The blade is typically made of high-quality steel and can range in length from 5 to 36 inches, depending on the specific model and intended use. The handles are usually made of wood or metal and are designed to provide a comfortable grip for the user.

The drawknife is used by pulling it towards the body, hence the name “draw” knife. This pulling motion allows the user to leverage their body weight and control the depth and angle of the cut, making it possible to remove large chunks of wood or make delicate shavings for fine shaping work.

While drawknives may seem simple in design, their effectiveness lies in this simplicity. The direct control they offer over the cutting process makes them a versatile tool that can be used in a wide range of woodworking tasks.

The History and Evolution of Drawknives

Drawknives have a long history and have been in use since ancient times. They were one of the first tools used by early humans for shaping wood, and their basic design has remained largely unchanged over the centuries. Early drawknives were made from flint or other hard stones, while later versions were made from bronze and iron.

With the advent of the industrial revolution in the 18th century, drawknives began to be mass-produced, leading to a standardization in their design and construction. Modern drawknives are typically made from high-quality steel and feature ergonomic handles for improved comfort and control.

Despite the proliferation of power tools in the 20th century, drawknives have remained a staple in the woodworker’s toolkit. Their versatility, control, and the unique connection they provide between the craftsman and the material continue to make them a preferred choice for many woodworkers.

The Role of Drawknives in Woodworking

Explanation of How Drawknives are Used in Shaping Wood

Drawknives are primarily used for shaping and smoothing wood. They are used by pulling the tool towards the body, allowing the user to control the depth and angle of the cut. This can be used to remove large chunks of wood for rough shaping work, or to make delicate shavings for fine shaping and smoothing.

The versatility of drawknives makes them suitable for a wide range of woodworking tasks. They can be used for debarking logs, shaping and fitting beams, and creating wooden furniture and sculptures. They are also commonly used in making wooden utensils, bowls, and other curved objects.

While drawknives can be used on any type of wood, they are particularly effective on green wood, which is softer and easier to shape. However, with a sharp blade and a skilled hand, drawknives can also be used on seasoned hardwoods.

Importance of Drawknives in Woodworking

Drawknives play a crucial role in woodworking. Their ability to remove large amounts of material quickly makes them an excellent tool for rough shaping work. At the same time, their unique design allows for a high level of control over the cutting process, making them suitable for fine shaping and smoothing work as well.

Moreover, the tactile connection that drawknives provide between the craftsman and the material is something that power tools often fail to replicate. This makes drawknives a preferred choice for projects that require a high level of detail and craftsmanship.

Whether you’re a professional woodworker or a hobbyist, having a drawknife in your toolkit can significantly enhance your woodworking skills and open up new possibilities for your projects.

Types of Drawknives

Straight Drawknives

Straight drawknives are the most common type of drawknife. They feature a straight blade that is ideal for general-purpose woodworking tasks. Straight drawknives are versatile and can be used for a wide range of tasks, from debarking logs to shaping and fitting beams.

The length of the blade can vary depending on the specific model and intended use. Longer blades are suitable for large-scale work, such as debarking logs or shaping large beams, while shorter blades are ideal for smaller, more detailed work.

Despite their simplicity, straight drawknives are highly effective and are a staple in any woodworker’s toolkit.

Curved Drawknives

Curved drawknives, as the name suggests, feature a curved blade. This curve allows the tool to make concave cuts, making it ideal for shaping curved objects such as bowls, spoons, and sculptures.

The degree of curve can vary from slight to pronounced, depending on the specific model and intended use. Curved drawknives with a slight curve are versatile and can be used for a wide range of tasks, while those with a pronounced curve are specialized tools designed for specific tasks.

While curved drawknives may require a bit more skill to use effectively, they are an invaluable tool for any woodworker looking to create curved objects.

Folding Drawknives

Folding drawknives are a modern variation of the traditional drawknife. They feature a blade that can be folded into the handle for safe storage and transport. This makes them a great option for woodworkers who need a portable tool that can be easily carried to different job sites.

Despite their compact size, folding drawknives are just as effective as their traditional counterparts. They are available in a variety of blade lengths and can be used for a wide range of woodworking tasks.

Whether you’re a professional woodworker on the go or a hobbyist looking for a compact tool for your home workshop, a folding drawknife can be a great addition to your toolkit.

Factors to Consider When Buying Drawknives

Quality of Steel

The quality of the steel used in the blade is one of the most important factors to consider when buying a drawknife. High-quality steel will hold an edge longer, making the tool more effective and reducing the need for frequent sharpening.

When evaluating the quality of the steel, consider factors such as hardness, toughness, and resistance to corrosion. Hardness determines how well the blade can hold an edge, while toughness refers to the blade’s ability to withstand impact without chipping or breaking. Resistance to corrosion is important for the longevity of the tool, especially if it will be used in a damp environment.

While high-quality steel may increase the cost of the drawknife, it is a worthwhile investment that will pay off in the long run through improved performance and durability.

Handle Material and Design

The material and design of the handles are another important factor to consider when buying a drawknife. The handles should be comfortable to hold and provide a secure grip to ensure safe and effective use of the tool.

Wooden handles are a popular choice due to their comfort and aesthetic appeal. However, they can be prone to cracking and may require regular maintenance to keep them in good condition. Metal handles are more durable and require less maintenance, but they can be less comfortable to hold, especially for extended periods.

The design of the handles should also be considered. Ergonomically designed handles that fit the shape of your hand can reduce fatigue and improve control, making the tool easier and more comfortable to use.

Size and Shape of the Blade

The size and shape of the blade are also important factors to consider when buying a drawknife. The right size and shape for you will depend on the specific tasks you plan to use the tool for.

Longer blades are suitable for large-scale work, such as debarking logs or shaping large beams, while shorter blades are ideal for smaller, more detailed work. Similarly, a straight blade is versatile and can be used for a wide range of tasks, while a curved blade is ideal for shaping curved objects.

When choosing the size and shape of the blade, consider your needs and the type of woodworking tasks you typically undertake. This will help you choose a drawknife that is well-suited to your needs and will be a valuable addition to your toolkit.

Understanding Blade Quality

Importance of Blade Quality in Drawknives

The quality of the blade is one of the most important factors that determine the performance and longevity of a drawknife. A high-quality blade will hold an edge longer, making the tool more effective and reducing the need for frequent sharpening. It will also be more durable and resistant to chipping or breaking, ensuring that the tool lasts for many years.

When evaluating the quality of the blade, consider factors such as the type of steel used, the hardness of the steel, and the quality of the heat treatment. High-quality steel with a high hardness rating and a proper heat treatment will ensure a blade that is sharp, durable, and long-lasting.

While a high-quality blade may increase the cost of the drawknife, it is a worthwhile investment that will pay off in the long run through improved performance and durability.

How to Determine Good Blade Quality

Determining the quality of a blade can be challenging, especially for beginners. However, there are a few key factors to look for that can give you an indication of the blade’s quality.

The type of steel used in the blade is one of the most important factors. High-quality steel such as high-carbon steel or tool steel is typically used in high-quality blades. These types of steel are known for their hardness and edge retention, making them ideal for drawknife blades.

The hardness of the steel is another important factor. Hardness is measured on the Rockwell C scale (HRC), with higher numbers indicating harder steel. A hardness rating of 58-62 HRC is generally considered good for drawknife blades.

The quality of the heat treatment is also important. Heat treatment is a process that alters the properties of the steel to improve its performance. A properly heat-treated blade will be more durable and hold an edge longer than a blade that has not been properly heat-treated.

Finally, the finish of the blade can also give you an indication of its quality. A well-finished blade will have a smooth, even surface with no visible defects or imperfections.

Handle Material and Design

Different Types of Handle Materials

The handles of a drawknife can be made from a variety of materials, each with its own advantages and disadvantages. The most common handle materials are wood and metal, although plastic and composite materials are also used.

Wooden handles are a popular choice due to their comfort and aesthetic appeal. They provide a warm, natural feel and can be carved into a variety of shapes to fit the user’s hand. However, wooden handles can be prone to cracking and may require regular maintenance to keep them in good condition.

Metal handles are more durable and require less maintenance than wooden handles. They are also more resistant to moisture, making them a good choice for use in damp environments. However, metal handles can be less comfortable to hold, especially for extended periods, and may become slippery when wet.

Plastic and composite handles are lightweight and require little to no maintenance. They are also resistant to moisture and can be molded into a variety of shapes for improved comfort and grip. However, they may not have the same aesthetic appeal as wooden or metal handles and may not be as durable.

Importance of Handle Design for Comfort and Control

The design of the handles is an important factor to consider when buying a drawknife. The handles should be comfortable to hold and provide a secure grip to ensure safe and effective use of the tool.

Ergonomically designed handles that fit the shape of your hand can reduce fatigue and improve control, making the tool easier and more comfortable to use. The handles should also be large enough to provide a secure grip, but not so large that they are difficult to hold.

The position of the handles relative to the blade is also important. The handles should be positioned at an angle that allows the user to pull the tool towards their body with a natural, comfortable motion. This will ensure that the user can apply the necessary force to the blade without straining their wrists or arms.

Size and Shape of the Blade

How the Size and Shape of the Blade Affect the Function

The size and shape of the blade are important factors that affect the function of a drawknife. The right size and shape for you will depend on the specific tasks you plan to use the tool for.

Longer blades are suitable for large-scale work, such as debarking logs or shaping large beams. They allow the user to remove large amounts of material quickly, making them an excellent tool for rough shaping work.

Shorter blades, on the other hand, are ideal for smaller, more detailed work. They provide a higher level of control over the cutting process, making them suitable for fine shaping and smoothing work.

The shape of the blade also affects the function of the tool. A straight blade is versatile and can be used for a wide range of tasks, while a curved blade is ideal for shaping curved objects.

Choosing the Right Size and Shape for Your Needs

When choosing the size and shape of the blade, consider your needs and the type of woodworking tasks you typically undertake. This will help you choose a drawknife that is well-suited to your needs and will be a valuable addition to your toolkit.

If you typically undertake large-scale work, such as debarking logs or shaping large beams, a drawknife with a long, straight blade may be the best choice for you. On the other hand, if you often do smaller, more detailed work, a drawknife with a short, curved blade may be more suitable.

Remember that the best drawknife for you is the one that fits your needs and feels comfortable in your hands. Don’t be afraid to try out different sizes and shapes to find the one that works best for you.

Maintenance of Drawknives

Proper Cleaning and Storage

Proper cleaning and storage are essential for maintaining the performance and longevity of your drawknife. After each use, the blade should be cleaned to remove any wood residue or moisture. This can be done with a cloth or a brush, and a mild detergent can be used if necessary.

Once the blade is clean, it should be dried thoroughly to prevent rust. A light coating of oil can also be applied to the blade to provide additional protection against rust.

The drawknife should be stored in a dry, cool place out of direct sunlight. If the drawknife has a sheath, it should be used to protect the blade during storage. If not, the blade can be wrapped in a cloth or paper to prevent damage.

Sharpening Techniques

Keeping the blade sharp is crucial for the performance of your drawknife. A sharp blade will cut more efficiently and require less effort to use, making your work easier and more enjoyable.

Sharpening a drawknife involves two steps: grinding and honing. Grinding is used to shape the edge and remove any nicks or chips, while honing is used to refine the edge and make it sharp.

Grinding can be done with a bench grinder or a coarse sharpening stone. The blade should be held at the correct angle (usually around 20-30 degrees) and moved across the stone in a smooth, controlled motion.

Honing is done with a fine sharpening stone or a strop. The blade is held at a slightly steeper angle than for grinding (usually around 30-35 degrees) and moved across the stone or strop in the same manner.

Sharpening a drawknife requires some skill and practice, but it is a crucial part of maintaining the tool and ensuring its performance and longevity.

Safety Measures When Using Drawknives

Proper Handling and Use

Proper handling and use are crucial for ensuring your safety when using a drawknife. The tool should be held firmly with both hands, and the blade should be pulled towards the body in a controlled manner. The user should always be aware of the position of their hands and body relative to the blade to avoid injury.

The workpiece should be securely clamped or held in a vice to prevent it from moving during use. The user should also ensure that they have a clear, unobstructed workspace and that there are no distractions that could cause them to lose focus or control of the tool.

Finally, the user should always wear appropriate safety gear, including safety glasses to protect the eyes from flying wood chips and a dust mask to prevent inhalation of wood dust.

Protective Gear

Wearing appropriate protective gear is crucial for ensuring your safety when using a drawknife. At a minimum, this should include safety glasses and a dust mask, but other gear may also be necessary depending on the specific task and conditions.

Safety glasses protect your eyes from flying wood chips and dust, which can cause serious injury. They should be worn at all times when using a drawknife.

A dust mask protects your lungs from inhaling wood dust, which can cause respiratory problems. It should be worn whenever you are working with wood, especially when making fine shavings or dust.

Other protective gear may include gloves to protect your hands, ear protection to protect your hearing from loud noises, and a shop apron to protect your clothes from wood chips and dust.

Popular Drawknife Brands

Overview of Top Drawknife Brands

There are many brands that manufacture drawknives, each with their own strengths and specialties. Some of the top brands include:

1. Gränsfors Bruks: This Swedish company is known for its high-quality, hand-forged tools. Their drawknives are made from high-carbon steel and feature ergonomic wooden handles.

2. Flexcut: This American company specializes in carving tools. Their drawknives are made from high-quality steel and feature comfortable, ergonomic handles.

3. BeaverCraft: This Ukrainian company offers a range of affordable, high-quality woodworking tools. Their drawknives are made from high-carbon steel

FAQ

What is a drawknife?

A drawknife is a hand tool used for shaping wood by pulling the blade towards the user, typically used for removing bark or shaping curved surfaces.

How do you use a drawknife?

Hold the tool with both hands, position the blade on the wood, and pull it towards you, using controlled pressure to remove material.

What are the benefits of using a drawknife?

It allows for precision shaping, removes material quickly, and is ideal for working on larger pieces of wood or curved surfaces.

Can a drawknife be used on other materials besides wood?

Drawknives are generally designed for wood but can also work on other soft materials with caution.

What is the difference between a drawknife and a spokeshave?

While both are used for shaping wood, a drawknife removes material faster and is better for rough shaping, while a spokeshave is used for finer, more detailed work.