Diagonal cutters, often referred to as side cutters or wire cutters, are an essential tool in various industries and for numerous DIY projects. These versatile tools are designed to cut through different materials, including wires, nails, and screws, making them indispensable for electricians, jewelers, and hobbyists alike. The importance of diagonal cutters cannot be overstated, as they provide a clean, precise cut that other tools may not achieve.

The purpose of this article is to provide a comprehensive guide on understanding diagonal cutters, their importance, factors to consider when purchasing, and how to maintain them. By the end of this guide, you will be equipped with the knowledge to make an informed decision when buying diagonal cutters and how to ensure they serve you effectively for a long time.

Whether you are a professional in need of a reliable tool for your trade or a DIY enthusiast looking for a versatile tool for your projects, this guide is for you. Let’s delve into the world of diagonal cutters and explore their many facets.

Our Top Diagonal Cutters Picks

HAUTMEC 8″ Wire Cutters

Check on AmazonKey Specs

- Material: Chrome Vanadium Steel with blackened anti-rust finish

- Cutting Edge Hardness: 62 HRC (laser-hardened)

- Functions: Cutting, stripping (1.5–6 mm²), and crimping (1.5–4 mm²)

- Handle: Ergonomic dual-component grip

- Cutting Power: 25% easier due to high-leverage rivet placement

The HAUTMEC 8-Inch Wire Cutters are built for serious, hands-on work. I like how the rivet is positioned closer to the jaws—it gives noticeably more leverage, translating to smoother, easier cuts even through tougher materials. The laser-hardened edges hold up impressively well over time, and the multi-zone grip fits snugly in hand without slipping. Whether I’m cutting, crimping, or stripping, the precision-machined surfaces and anti-corrosion finish make these pliers feel dependable and professional every time.

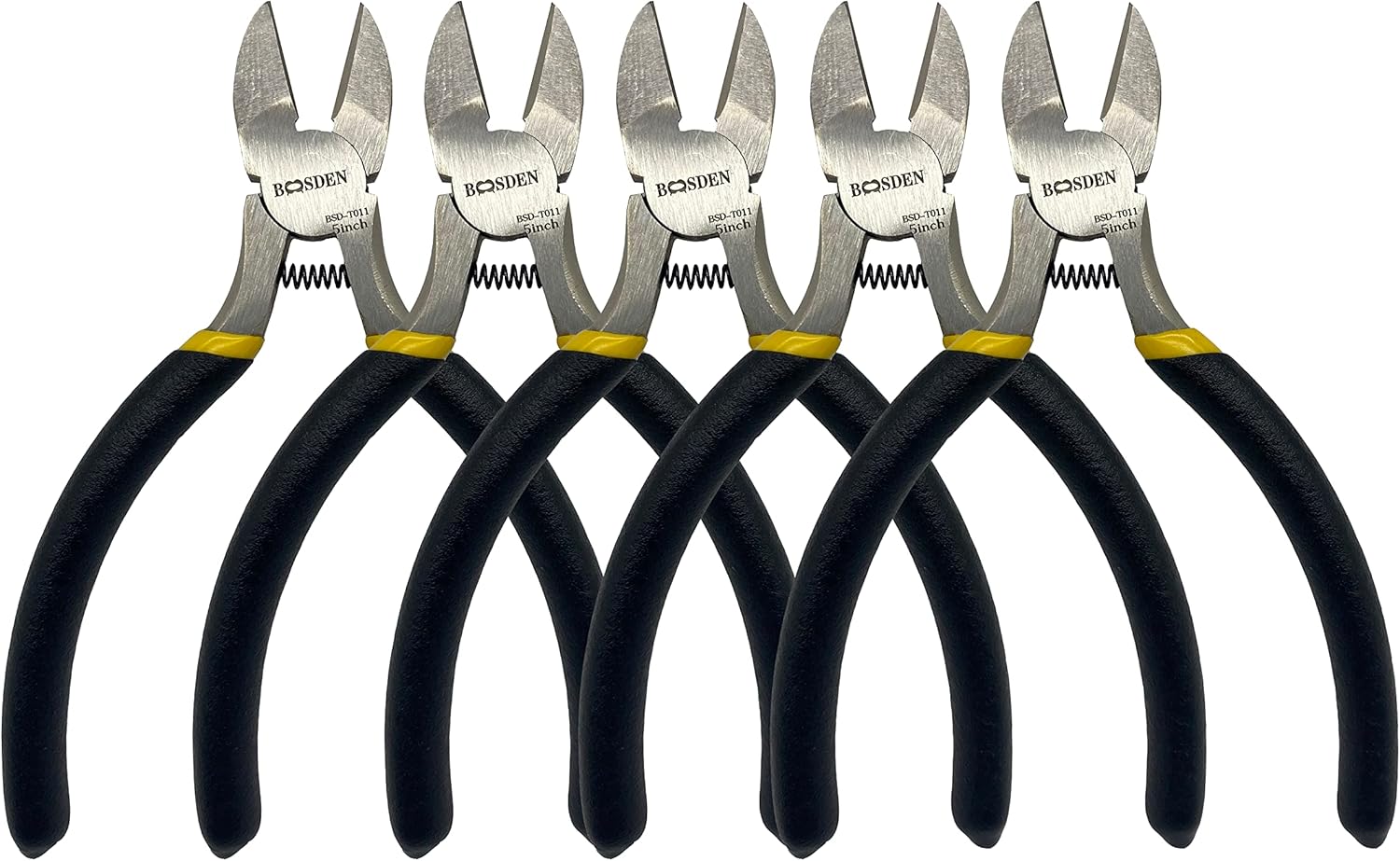

BOOSDEN 5″ Diagonal Cutters

Check on Amazon

Key Specs:

- Size: 5 inches (5-piece pack)

- Material: High-frequency quenched carbon steel

- Handle: Rubber-coated, non-slip grip

- Use: Ideal for jewelry, cords, beads, and fine trimming

- Packaging: Individually packed with protective oil finish

The BOOSDEN 5-Inch Diagonal Cutters are compact and well-suited for detailed, precision tasks like jewelry making and small electronics. I appreciate the rubber-coated, non-slip handles—they give a comfortable grip even during repetitive cutting. Despite their size, the carbon steel construction provides surprising durability, especially with the added protection from high-frequency quenching. These cutters excel in trimming soft wires, beads, or cord with clean results. Plus, the inclusion of protective oil right out of the package shows a thoughtful approach to tool longevity.

DURATECH 7″ High Leverage Diagonal Cutters

Check on Amazon

Key Specs:

- Size: 7 inches, weighs 0.59 pounds

- Material: Chrome-Nickel alloy steel

- Cutting Capacity: Up to 2 millimeters steel wire

- Grip: Ergonomic, non-slip handles

- Standard: ANSI compliant

The DURATECH 7-Inch High Leverage Diagonal Cutters feel like a true workhorse in my tool collection. What stands out is the forward-placed pivot point—it genuinely boosts leverage, allowing me to cut through thicker wires with noticeably less force. The Cr-Ni alloy construction offers solid corrosion resistance, and I’ve found it to maintain sharpness well. The angled blades make clean, flush cuts every time, even on tough steel. For a cutter that balances comfort, precision, and toughness, this one delivers.

KNIPEX – 74 01 160 Tools – High Leverage Diagonal Cutters

Check on Amazon

Key Specs:

- Length: 160 millimeters (approx. 6.3 inches)

- Material: Chrome Vanadium steel

- Weight: 0.41 pounds

- Compliance: DIN ISO 5749 standard

- Grip Type: Ergonomic plastic-coated handles

The KNIPEX 74 01 160 High Leverage Diagonal Cutters are a serious upgrade if you’re after precision and power in a compact tool. What I appreciate most is the German engineering behind these cutters—every cut feels intentional and efficient. The chrome vanadium steel construction delivers exceptional edge retention, and the high-leverage design genuinely reduces effort, especially when dealing with hardened wires. These feel rock-solid in hand, and the ergonomic grip makes prolonged use far more comfortable than most.

Professional Wire Cutters

Check on Amazon

Key Specs:

- Material: Chrome Vanadium Steel

- Length: 6 inches

- Grip Type: Ergonomic, anti-fatigue

- Functions: Cutting, crimping, gripping, twisting

- Warranty: Lifetime guarantee from Ainuosen

The Ainuosen Professional Wire Cutters blend durability with everyday functionality. What really stands out is the spring-loaded mechanism—it noticeably reduces hand fatigue during repetitive cutting or crimping tasks. Made from forged chrome vanadium steel, these pliers handle tough jobs with ease, and the machined jaws offer solid gripping power. I also like the added crimping feature, which makes it more versatile without feeling bulky. The anti-rust coating is a subtle but welcome bonus for longevity in humid or workshop environments.

Understanding Diagonal Cutters

Diagonal cutters are a type of pliers designed to cut through various materials. They are characterized by their diagonal design, which allows for a more precise cut compared to other types of cutters. The cutting edge of diagonal cutters is typically made from high-quality steel to ensure durability and effectiveness.

There are different types of diagonal cutters available in the market, each designed for a specific purpose. For instance, high-leverage diagonal cutters are ideal for heavy-duty cutting tasks, while flush cut diagonal cutters are perfect for precision cutting. Understanding the different types of diagonal cutters and their functions can help you choose the right tool for your needs.

Some diagonal cutters come with additional features such as insulated handles for safety or spring-loaded jaws for ease of use. These features can significantly enhance the user experience, making the tool more efficient and comfortable to use.

Importance of Diagonal Cutters

Diagonal cutters play a crucial role in various industries. Electricians use them to cut and strip wires, jewelers use them to cut and shape precious metals, and mechanics use them to cut through small metal components. Their ability to provide a clean, precise cut makes them an essential tool in these industries.

Aside from their industrial use, diagonal cutters are also important for DIY projects. Whether you’re assembling furniture, creating jewelry, or working on a home improvement project, a pair of diagonal cutters can come in handy. They can cut through materials that other tools can’t, making your project easier and more efficient.

Moreover, the importance of diagonal cutters extends to safety. Using the right tool for the job can significantly reduce the risk of accidents. For instance, trying to cut a wire with a knife or a pair of scissors can result in injury. A pair of diagonal cutters, on the other hand, can cut through the wire safely and efficiently.

Factors to Consider When Buying Diagonal Cutters

When buying diagonal cutters, the quality of the material is one of the most important factors to consider. The best diagonal cutters are typically made from high-quality steel, which ensures durability and effectiveness. Cheap, low-quality cutters may not provide a clean cut and can even damage the material you’re working on.

Size and weight are also important factors to consider. The right size and weight depend on the task at hand and your personal preference. For heavy-duty tasks, a larger, heavier pair of cutters may be more suitable. For precision tasks, a smaller, lighter pair may be more appropriate. It’s also important to consider the comfort and grip of the handle. A comfortable, non-slip grip can make the tool easier to use and reduce hand fatigue.

Lastly, consider the cutting capacity of the diagonal cutters. This refers to the size and type of material the cutters can handle. Make sure to choose a pair of cutters that can handle the materials you’ll be working with.

Understanding the Cutting Edge

The sharpness of the cutting edge is crucial for the performance of diagonal cutters. A sharp cutting edge can provide a clean, precise cut, while a dull edge can result in a messy cut and even damage the material. Therefore, it’s important to keep the cutting edge sharp and well-maintained.

The material of the cutting edge also plays a significant role in its performance. High-quality steel is often used for the cutting edge due to its durability and sharpness. Some cutting edges are also coated with a hard material such as titanium to enhance their durability and cutting performance.

Maintenance is key for a long-lasting sharp cutting edge. This includes regular sharpening and cleaning to remove any debris that may dull the edge. With proper maintenance, your diagonal cutters can serve you effectively for a long time.

The Role of the Handle in Diagonal Cutters

The handle plays a significant role in the performance and user experience of diagonal cutters. The material and design of the handle can impact its comfort and grip. Handles made from soft, non-slip materials can provide a comfortable grip and reduce hand fatigue. The design of the handle, such as its shape and size, can also affect its comfort and ease of use.

The handle can also impact the efficiency of the tool. For instance, a handle with a spring-loaded design can make the tool easier to use by automatically opening the jaws after each cut. This can make your work more efficient, especially for repetitive cutting tasks.

Lastly, the handle can also feature safety elements such as insulation. Insulated handles can protect you from electric shocks when working with live wires, making the tool safer to use.

Safety Features in Diagonal Cutters

Safety should always be a priority when using tools, and diagonal cutters are no exception. One of the key safety features in diagonal cutters is the locking mechanism. This feature allows you to lock the jaws of the cutters when not in use, preventing accidental cuts and injuries.

Insulated handles are another important safety feature. As mentioned earlier, they can protect you from electric shocks when working with live wires. Some diagonal cutters also feature a safety stop that prevents the jaws from closing completely, protecting the cutting edge from damage.

When choosing diagonal cutters, make sure to consider these safety features. They can not only protect you from accidents but also extend the lifespan of the tool.

Brand Reputation and Reviews

When buying diagonal cutters, it’s important to consider the reputation of the brand. Reputable brands are often more reliable and offer better quality products. They also typically provide better customer service, including warranties and after-sales service.

Customer reviews can also provide valuable insights into the performance and quality of the product. They can give you a better idea of what to expect from the product and help you make an informed decision. However, keep in mind that not all reviews are reliable, so it’s important to read them with a critical eye.

Remember, a higher price doesn’t always mean better quality. It’s important to balance quality and affordability to get the best value for your money.

Price Considerations

Understanding the price range of diagonal cutters can help you budget appropriately and avoid overpaying. The price of diagonal cutters can vary widely depending on the brand, quality, and features of the product. High-end diagonal cutters with advanced features and superior quality materials can be quite expensive, while basic models are more affordable.

While it’s important to consider your budget, it’s equally important to consider the quality and features of the product. A cheap pair of diagonal cutters may not last long or provide a clean cut, costing you more in the long run. On the other hand, an expensive pair with features you don’t need may not be a wise investment.

Therefore, it’s important to balance quality and affordability. Consider what features and quality you need and choose a product that offers the best value for your money.

Maintenance and Care for Diagonal Cutters

Proper maintenance and care can extend the lifespan of your diagonal cutters and ensure they continue to perform effectively. This includes regular cleaning to remove any debris that may dull the cutting edge. After cleaning, it’s important to dry the cutters thoroughly to prevent rusting.

Sharpening the cutting edge regularly can also help maintain its performance. However, it’s important to do this correctly to avoid damaging the edge. If you’re not confident in doing this yourself, consider getting it done by a professional.

Lastly, consider the replacement of parts. Over time, parts such as the cutting edge or the spring in the handle may wear out and need replacement. Some brands offer replacement parts, which can be more cost-effective than buying a new pair of cutters.

Environmental Considerations

When choosing diagonal cutters, it’s also important to consider their environmental impact. This includes the sustainability of the production process and the recyclability of the tool. Some brands are committed to sustainable practices, such as using recycled materials or reducing energy consumption in production.

The recyclability of the tool is also important. Some diagonal cutters are made from materials that can be recycled, reducing their environmental impact. However, keep in mind that not all parts of the tool may be recyclable. For instance, the rubber handles or the spring may not be recyclable.

By choosing environmentally friendly diagonal cutters, you can contribute to the conservation of our planet while enjoying a high-quality tool.

Conclusion

In conclusion, diagonal cutters are an essential tool in various industries and for numerous DIY projects. Understanding their features, importance, and how to maintain them can help you make an informed decision when buying and ensure they serve you effectively for a long time.

When choosing diagonal cutters, consider factors such as the quality of the material, size and weight, handle comfort and grip, and cutting capacity. Also, consider safety features, brand reputation, price, and environmental considerations. With the right pair of diagonal cutters, you can achieve clean, precise cuts every time.

Remember, a good pair of diagonal cutters is an investment. With proper care and maintenance, they can serve you effectively for many years. So, choose wisely and happy cutting!

FAQ

What are diagonal cutters used for?

Diagonal cutters are used for cutting various materials, including wires, nails, and screws. They are commonly used by electricians, jewelers, and mechanics, as well as for DIY projects.

How do I maintain my diagonal cutters?

Maintain your diagonal cutters by cleaning them regularly, sharpening the cutting edge as needed, and replacing worn-out parts. Also, store them in a dry place to prevent rusting.

What should I consider when buying diagonal cutters?

When buying diagonal cutters, consider the quality of the material, size and weight, handle comfort and grip, cutting capacity, safety features, brand reputation, price, and environmental considerations.