Brief overview of Dado Blades

Dado blades are a crucial tool in the woodworking industry. They are unique cutting tools designed to make precise cuts in various types of wood. Unlike regular saw blades that make simple cuts, dado blades are engineered to create grooves, slots, and dadoes in wood pieces. These cuts are essential in the construction of high-quality furniture and cabinetry.

The versatility of dado blades makes them a must-have tool for both professional woodworkers and DIY enthusiasts. They are designed to fit into different types of table saws and are capable of making a variety of cuts, making them an indispensable tool in any woodworking shop.

Despite their importance, dado blades are often overlooked by beginners in woodworking. Understanding the functionality, types, and proper usage of dado blades can significantly improve the quality of your woodworking projects.

Our Top Dado Blades Picks

The Mibro Group 416381 Carbide Stacking Dado Blade

Check on AmazonKey Specs

- Blades: Two 8-inch outer blades, five two-wing chippers

- Slot Widths: 1/4″ to 13/16″ in 1/16″ increments

- Teeth: 24 carbide teeth with negative hook angles

- Material Compatibility: Engineered wood and solid wood

- Case: Durable case with internal dividers for secure storage

The Mibro Group 416381 Carbide Stacking Dado Blade is a must-have for anyone looking to create smooth, precise grooves in engineered wood and solid wood. This set includes two outer 8-inch blades, five two-wing chippers, and seven metal shims, providing a wide range of adjustments for slot widths from 1/4″ to 13/16″. The carbide teeth and negative hook angles ensure clean, splinter-free cuts with flat bottoms and square shoulders. The durable case keeps all components organized and secure.

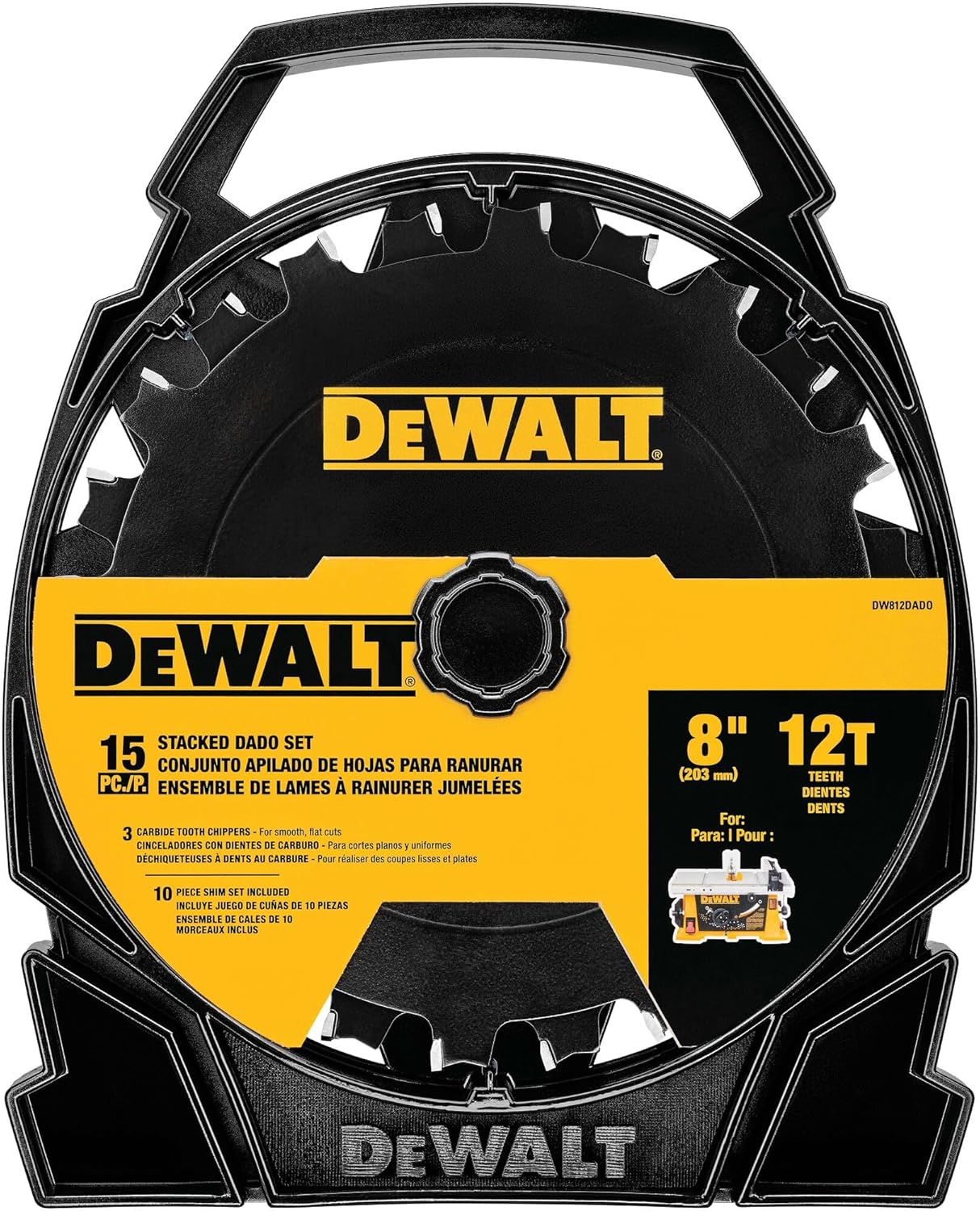

DEWALT Stacked Dado Saw Blade

Check on Amazon

Key Specs:

- Teeth: 12 micro-grain carbide teeth

- Blades: 4 tooth chippers for flat bottom cuts

- Material Compatibility: Engineered wood

- Adjustment: Stainless steel shims for fine adjustments

- Storage: Heavy-duty storage case for protection

The DEWALT Stacked Dado Saw Blade offers exceptional precision and durability for professionals who require smooth, flat bottom cuts in engineered wood. Its heavy gauge, laser-cut plates ensure accurate cuts every time, while the 4-tooth chippers help achieve a smooth finish. The micro-grain carbide teeth provide clean cuts with minimal splintering, and the stainless steel shims allow for ultra-fine width adjustments. This set comes with a heavy-duty storage case to protect the blades from damage, making it a reliable and long-lasting tool.

CMT ORANGE TOOLS 230.312.08 DADO Set Saw Blade

Check on Amazon

Key Specs:

- Teeth: 12 (Flat Top Grind + Alternate Top Bevel)

- Coating: ORANGE SHIELD for heat, gumming, and corrosion resistance

- Material Compatibility: Solid wood, laminates, melamines, veneer plywood

- Adjustment: Includes plastic & magnetic shims, lock spacers for micro-thin adjustability

- Compliance: UNI EN847 compliant for safety during rotation

The CMT ORANGE TOOLS 230.312.08 DADO Set Saw Blade is a groundbreaking tool that ensures unmatched precision and safety, being the first Dado ever deemed UNI EN847 compliant. This unique feature prevents assembled elements from coming into contact with each other while rotating. The blade’s design provides clean, flat-bottom grooves with virtually splinter-free cuts, making it perfect for solid wood, laminates, melamines, and veneer plywood. The ORANGE SHIELD COATING enhances the blade’s durability by protecting against heat, gumming, and corrosion. It also includes shims and plastic “lock spacers” for fine adjustments.

OSHLUN SDS-0630 6-Inch 30 Tooth Stack Dado Set

Check on Amazon

Key Specs:

- Teeth: 30 precision ground carbide tips

- Material: Professional-grade C-4 carbide

- Groove Type: Flat-bottom grooves

- Adjustment: Includes shim set for fine adjustments

- Storage: Comes with a carrying case (style may vary)

The OSHLUN SDS-0630 6-Inch 30 Tooth Stack Dado Set is a professional-grade tool designed for precision and durability. Its C-4 carbide construction ensures long-lasting sharpness, while the full-body chippers and precision-ground carbide tips provide smooth, accurate cuts. This set is perfect for creating flat-bottom grooves with ease. The included shim set allows for fine adjustments, ensuring that you can achieve the exact slot width you need. For added convenience, it comes with a carrying case (style may vary) for safe and organized storage.

Kempston 99312 10-Inch by 24 Tooth Industrial Rip Thick Kerf Blade

Check on Amazon

Key Specs:

- Teeth: 24 premium carbide teeth

- Blade Material: Industrial-grade thick kerf carbide

- Design: Laser-cut body, anti-kickback design

- Size: 10-inch diameter

- Weight: 2.01 pounds

The Kempston 99312 10-Inch by 24 Tooth Industrial Rip Thick Kerf Blade is designed for high-performance cutting of wood. Featuring an industrial-grade thick kerf design, this blade is equipped with premium carbide teeth for durability and long-lasting sharpness. The laser-cut body ensures precise cuts, while the anti-kickback design enhances safety during use. CNC precision grinding adds to the blade’s accuracy and performance, making it ideal for rip cuts in thick wood materials.

Importance of Dado Blades in woodworking

Dado blades play a significant role in woodworking. They are primarily used to cut precise, flat-bottomed grooves in wood. These grooves are essential in the construction of bookshelves, cabinets, and other types of furniture where panels or shelves need to be fitted into the sides of the structure.

Without dado blades, making such cuts would be time-consuming and less accurate. The precision offered by these blades ensures that the pieces fit together perfectly, resulting in a sturdy and high-quality finished product.

Moreover, dado blades can also be used to create decorative effects in woodworking projects. By adjusting the width and depth of the cut, woodworkers can create unique designs and patterns, adding an artistic touch to their creations.

Understanding Dado Blades

Definition of Dado Blades

Dado blades are specialized types of circular saw blades used to cut grooves, also known as dadoes, in wood. These blades are designed to cut wider paths in a single pass, unlike regular saw blades that require multiple passes to achieve the same width. This makes dado blades highly efficient and time-saving tools in woodworking.

The term “dado” refers to the groove or slot cut into a piece of wood. This groove is typically used to fit another piece of wood snugly, creating a strong and seamless joint. Dado blades are the go-to tools for creating such joints due to their precision and efficiency.

While they may seem complex at first glance, dado blades are relatively easy to use once you understand their components and how they work. They are a valuable addition to any woodworking shop, offering a level of versatility that is hard to match with other cutting tools.

Types of Dado Blades

There are three main types of dado blades: stacked dado blade sets, wobble dado blades, and adjustable dado blades. Each type has its unique features and is suited for different applications.

Stacked dado blade sets consist of two outer blades and a series of inner chippers. The outer blades cut the edges of the dado, while the chippers remove the material in between. By adjusting the number and thickness of the chippers, you can control the width of the cut.

Wobble dado blades, on the other hand, consist of a single blade mounted on an adjustable hub. As the blade spins, it wobbles from side to side, cutting a wider path. The width of the cut can be adjusted by changing the degree of wobble.

Lastly, adjustable dado blades are a newer type of dado blade that combines the best features of stacked and wobble blades. They consist of two blades that can be adjusted to cut a range of widths without the need for chippers or shims.

Components of Dado Blades

The main components of a dado blade are the outer blades, chippers, and shims. The outer blades are the main cutting elements, while the chippers and shims are used to adjust the width of the cut.

The outer blades in a stacked dado set are similar to regular saw blades. They have teeth around the edge that cut through the wood. The number and design of the teeth can vary depending on the type of cut the blade is designed to make.

The chippers in a stacked dado set are smaller blades that fit between the outer blades. They have fewer teeth and are designed to remove the material in the middle of the cut. The number and thickness of the chippers used determine the width of the cut.

Shims are thin pieces of metal or plastic that are used to fine-tune the width of the cut. They are placed between the chippers and the outer blades in a stacked dado set. By adding or removing shims, you can adjust the width of the cut to a high degree of precision.

Factors to Consider When Buying Dado Blades

Material Quality

The quality of the material used to make the dado blade is a crucial factor to consider. High-quality blades are typically made from carbide, a material known for its durability and sharpness. Carbide-tipped blades can withstand heavy use and maintain their sharpness for a long time, making them a good investment for serious woodworkers.

However, not all carbide blades are created equal. The quality can vary depending on the manufacturing process and the grade of carbide used. It’s important to research and choose a reputable brand to ensure you’re getting a high-quality blade.

Another factor to consider is the thickness of the carbide tips. Thicker tips can be resharpened more times, extending the life of the blade. However, they also tend to be more expensive.

Blade Size

The size of the blade is another important factor to consider. Dado blades come in various sizes, with 6-inch and 8-inch blades being the most common. The size you choose should depend on the type of work you plan to do and the capacity of your table saw.

Smaller blades are suitable for lighter work and smaller table saws. They are easier to handle and less expensive. However, they may not be able to handle heavy-duty tasks or cut through thick materials.

Larger blades, on the other hand, are capable of making deeper cuts and handling heavier tasks. However, they require a more powerful table saw and can be more difficult to handle. They are also more expensive.

Type of Cut

The type of cut you plan to make is another factor to consider when choosing a dado blade. Different blades are designed to make different types of cuts, and choosing the right one can significantly improve the quality of your work.

For example, if you plan to make a lot of crosscuts, you should choose a blade with a high tooth count. These blades produce a smoother cut and are less likely to tear the wood. On the other hand, if you plan to make a lot of rip cuts, a blade with a lower tooth count would be more suitable. These blades cut faster and are less likely to burn the wood.

It’s also important to consider the type of material you plan to cut. Some blades are designed to cut through hardwood, while others are better suited for softwood or plywood. Choosing the right blade for the material can help prevent damage and ensure a clean cut.

Compatibility with your tools

Before buying a dado blade, it’s important to check whether it’s compatible with your table saw. Not all table saws can accommodate dado blades, and even those that can may have limitations on the size or type of blade they can handle.

Check the specifications of your table saw to determine the maximum blade size it can accommodate. Also, check whether it has a standard or arbor hole size. Most dado blades have a 5/8-inch arbor hole, but some table saws may require a different size.

It’s also important to check whether your table saw has enough power to handle a dado blade. Dado blades require more power than regular blades due to their larger size and the wider cuts they make. If your table saw doesn’t have enough power, it may struggle to spin the blade, resulting in poor performance and potential damage to the saw.

Price and Brand

The price of the dado blade is another important factor to consider. Like any tool, you get what you pay for with dado blades. Cheaper blades may seem like a good deal, but they often use lower-quality materials and may not last as long or perform as well as more expensive blades.

It’s worth investing in a high-quality blade from a reputable brand. These blades are typically made from better materials and have a more precise manufacturing process, resulting in a sharper, more durable blade.

However, it’s also important to consider your budget and the type of work you plan to do. If you’re a hobbyist or beginner, a mid-range blade may be sufficient. If you’re a professional woodworker or plan to use the blade heavily, it may be worth investing in a top-of-the-line blade.

Detailed Review of Different Dado Blades

Stacked Dado Blade Sets

Stacked dado blade sets are the most common type of dado blade. They consist of two outer blades and a series of chippers that fit between them. The outer blades cut the edges of the dado, while the chippers remove the material in between.

One of the main advantages of stacked dado sets is their versatility. By adjusting the number and thickness of the chippers, you can control the width of the cut. This allows you to make a wide range of cuts with a single blade set.

However, stacked dado sets can be more difficult to set up than other types of blades. They require careful adjustment to ensure the width of the cut is accurate. They can also be more expensive due to the number of components involved.

Wobble Dado Blades

Wobble dado blades are a simpler and less expensive alternative to stacked dado sets. They consist of a single blade mounted on an adjustable hub. As the blade spins, it wobbles from side to side, cutting a wider path.

The main advantage of wobble blades is their simplicity. They are easy to set up and adjust, making them a good choice for beginners or those who don’t need to make a wide range of cuts.

However, wobble blades have some limitations. They can’t make as wide a cut as stacked dado sets, and the quality of the cut may not be as good. The wobbling action can cause the bottom of the cut to be slightly rounded, rather than perfectly flat.

Adjustable Dado Blades

Adjustable dado blades are a newer type of dado blade that combines the best features of stacked and wobble blades. They consist of two blades that can be adjusted to cut a range of widths without the need for chippers or shims.

The main advantage of adjustable blades is their convenience. They are easy to set up and adjust, and they can make a wide range of cuts. They also produce a high-quality cut, with a flat bottom and clean edges.

However, adjustable blades can be more expensive than other types of dado blades. They also require careful adjustment to ensure the width of the cut is accurate.

How to Use Dado Blades for Perfect Cuts

Safety Measures

Like any power tool, dado blades can be dangerous if not used properly. It’s important to follow safety measures to prevent accidents and injuries.

First and foremost, always wear safety gear when using a dado blade. This includes safety glasses to protect your eyes from flying debris, ear protection to protect your hearing from the noise of the saw, and a dust mask to prevent inhalation of sawdust.

Never reach over the blade while it’s spinning, and always wait for the blade to stop completely before adjusting it or removing cut pieces. Keep your hands well away from the blade while it’s in use, and use push sticks or featherboards to guide the wood through the cut.

Finally, always check the blade and the saw before use to ensure they are in good condition and properly installed. A loose or damaged blade can be extremely dangerous.

Installation Process

Installing a dado blade is a relatively straightforward process, but it’s important to do it correctly to ensure the blade works properly and safely.

First, unplug the table saw to prevent accidental startup. Remove the existing blade and clean the arbor and the blade guard to remove any dust or debris.

Next, install the outer blades and chippers according to the manufacturer’s instructions. Make sure the teeth of the blades and chippers are staggered to prevent them from hitting each other. If you’re using shims, place them between the chippers and the outer blades to adjust the width of the cut.

Once the blades and chippers are installed, secure the arbor nut and check the alignment of the blades. They should be perfectly parallel to the miter slot and the fence. If they’re not, adjust the alignment before proceeding.

Finally, reinstall the blade guard and plug in the saw. Make a test cut to check the width and quality of the cut. If necessary, adjust the blades or the fence to achieve the desired result.

Cutting Techniques

Using a dado blade requires some different techniques than using a regular saw blade. Here are some tips to help you make perfect cuts every time.

First, always make a test cut before cutting your actual workpiece. This allows you to check the width and quality of the cut and make any necessary adjustments.

When making the cut, feed the wood slowly and steadily through the blade. Don’t force the wood or rush the cut, as this can result in a rough or inaccurate cut.

Keep the wood firmly against the fence and the table to ensure it stays straight and level. Use push sticks or featherboards to guide the wood and keep your hands away from the blade.

Finally, always cut with the grain of the wood, not against it. This helps prevent tear-out and ensures a smoother cut.

Maintenance and Care for Dado Blades

Cleaning Process

Regular cleaning is essential to maintain the performance and longevity of your dado blades. Over time, resin and sawdust can build up on the blades, reducing their cutting efficiency and potentially causing them to overheat.

To clean your blades, first remove them from the saw and wipe off any loose dust or debris. Then, soak them in a blade cleaner or a solution of warm water and mild detergent for about 15 minutes. Use a soft brush to scrub off any stubborn residue, then rinse the blades and dry them thoroughly.

After cleaning, apply a thin coat of blade lubricant to prevent rust and reduce friction. Store the blades in a dry, clean place to keep them in good condition.

Sharpening Techniques

Keeping your blades sharp is crucial for maintaining their cutting performance. Dull blades can cause rough cuts, burn marks, and increased wear on your table saw.

Sharpening a dado blade requires a bit more skill than sharpening a regular blade due to the multiple components involved. It’s important to sharpen each component evenly to maintain the balance of the blade.

If you’re not confident in your sharpening skills, it’s best to have your blades sharpened by a professional. They have the tools and expertise to sharpen your blades accurately and safely.

Storage Tips

Proper storage is important to protect your blades from damage and extend their lifespan. Store your blades in a dry, clean place to prevent rust and dust buildup. If possible, store them in a blade holder or a case to protect them from accidental damage.

Never stack blades directly on top of each other, as this can cause the teeth to chip or dull. If you need to stack them, place a piece of cardboard or wood between each blade to protect the teeth.

Finally, always handle your blades with care. Even a small drop or bump can damage the teeth or throw the blade out of balance.

Conclusion

Recap of the importance and usage of Dado Blades

Dado blades are a valuable tool in any woodworking shop. They allow you to make precise, wide cuts in a single pass, saving time and improving the quality of your work. They are essential for creating strong, seamless joints in furniture and cabinetry, and they can also be used to create decorative effects in your projects.

Choosing the right dado blade requires careful consideration of several factors, including the quality of the material, the size of the blade, the type of cut you plan to make, the compatibility with your table saw, and the price and brand. By understanding these factors and how they affect the performance of the blade, you can choose the best blade for your needs.

Once you have chosen a blade, it’s important to use it correctly and safely. Follow the manufacturer’s instructions for installation and adjustment, and always use safety measures when operating the saw. Regular maintenance and care, including cleaning, sharpening, and proper storage, can extend the life of your blades and keep them performing at their best.

Final thoughts on choosing the right Dado Blades for woodworking

Choosing the right dado blade can make a significant difference in the quality of your woodworking projects. Whether you’re a professional woodworker or a DIY enthusiast, a high-quality dado blade is a worthwhile investment.

Remember, the best blade for you depends on your specific needs and the type of work you plan to do. Don’t be afraid to invest in a high-quality blade from a reputable brand, as it will likely perform better and last longer than a cheaper alternative.

With the right blade and proper usage, you can create beautiful, precise cuts and take your woodworking projects to the next level.

FAQ Section

Here are some frequently asked questions about dado blades:

What is a dado blade?

A dado blade is a specialized type of circular saw blade used to cut wide, flat-bottomed grooves in wood. These grooves, also known as dadoes, are used to fit another piece of wood snugly, creating a strong and seamless joint.

What are the different types of dado blades?

There are three main types of dado blades: stacked dado blade sets, wobble dado blades, and adjustable dado blades. Each type has its unique features and is suited for different applications.

How do I choose the right dado blade?

Choosing the right dado blade depends on several factors, including the quality of the material, the size of the blade, the type of cut you plan to make, the compatibility with your table saw, and the price and brand.

How do I use a dado blade safely?

Always wear safety gear, including safety glasses, ear protection, and a dust mask. Never reach over the blade while it’s spinning, and always wait for the blade to stop completely before adjusting it or removing cut pieces. Use push sticks or featherboards to guide the wood through the cut.

How do I maintain my dado blades?

Regular cleaning, sharpening, and proper storage can extend the life of your blades and keep them