Boat varnish, an often overlooked aspect of boat maintenance, plays a crucial role in preserving the longevity and enhancing the aesthetic appeal of a boat. This protective coating shields the boat from harsh environmental conditions, including UV rays, saltwater, and extreme temperatures, thereby preventing the wood from rotting, peeling, or cracking. Moreover, a well-varnished boat is a sight to behold, with its glossy finish reflecting the sun’s rays and the water’s shimmer.

The purpose of this comprehensive guide is to delve into the world of boat varnish, providing boat owners with valuable insights into its importance, types, and application process. It also aims to equip readers with the knowledge to choose the right varnish for their boat, understand varnish labels, and maintain varnished surfaces, among other things.

Whether you’re a seasoned boat owner or a novice, this guide will serve as a valuable resource in your boat maintenance journey, helping you protect your investment and keep your boat looking its best for years to come.

Our Top Boat Varnish Picks

Rust-Oleum 207008 Marine Spar Varnish

Check on AmazonKey Specs:

- Coverage: 75-150 sq. ft.

- Finish: Gloss clear

- Dry Time: Dries to touch in 2 hours

- Material Compatibility: Wood

- Durability: UV, salt, and mildew resistant

The Rust-Oleum 207008 Marine Spar Varnish is a top choice for protecting exterior wood surfaces. I love how its oil-based formula expands and contracts with weather conditions, making it perfect for areas exposed to the elements, like trim, railings, and furniture. The UV, salt, and mildew resistance is excellent, offering twice the durability of conventional wood finishes. Its crystal-clear gloss finish adds a stunning shine while providing superior protection, making it ideal for boats and outdoor projects.

TotalBoat – 409314 Gleam Marine Spar Varnish

Check on AmazonKey Specs:

- Coverage: 360-400 sq ft/gallon

- Finish: Gloss or Satin

- Application Method: Brush, roll, or spray

- Dry Time: Recoat in 1 hour at 72°F

- Material Compatibility: Wood (boats, furniture, etc.)

The TotalBoat 409314 Gleam Marine Spar Varnish is a standout choice for wood protection. The premium tung oil and phenolic resins create a durable, transparent amber finish that enhances wood while offering maximum UV resistance. I appreciate how it remains flexible after curing, preventing cracks or peeling despite the seasonal changes. Whether you’re working on boats, furniture, or kayaks, this self-leveling varnish ensures a smooth, flawless finish. It dries quickly, allowing multiple coats in a single day, making it efficient and effective.

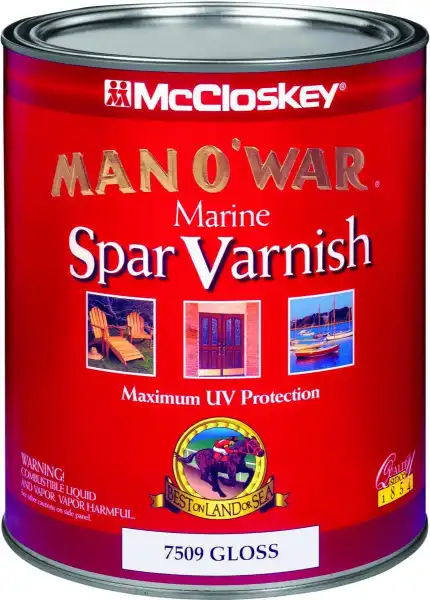

Valspar 80-7509 Man O’ War Spar Varnish

Check on AmazonKey Specs:

- Coverage: 300-500 sq.ft. per gallon

- Finish: Gloss

- Material: Tung Oil

- Recommended Use: Interior and exterior wood

- Item Weight: 2.12 pounds

The Valspar 80-7509 Man O’ War Spar Varnish is an excellent choice for anyone seeking premium outdoor protection. The tung oil-based formula provides a rich, glossy finish that not only enhances the wood but also offers superior resistance to the sun and weather. I love using this varnish for wooden doors, sills, and outdoor furniture as it protects and beautifies with extra durability. Its VOC formula ensures it’s more eco-friendly while still offering exceptional performance and coverage.

TotalBoat-497712 Halcyon Marine Varnish

Check on AmazonKey Specs:

- Coverage: 80-100 sq. ft./quart

- Finish: Gloss

- Material: Polyurethane

- Recommended Use: Interior and exterior wood

- Item Weight: 2.17 pounds

The TotalBoat Halcyon Marine Varnish is a fantastic choice for anyone seeking a durable, water-based polyurethane finish. I love how it dries quickly, allowing me to apply up to 5 coats in a single day—no sanding between coats required! This varnish provides superior UV protection, abrasion resistance, and flexibility, making it perfect for both interior and exterior wood surfaces, especially on boats and furniture. Cleanup is a breeze with just soap and water. A must-have for a long-lasting, glossy finish.

Understanding Boat Varnish

Boat varnish, also known as marine varnish, is a protective finish designed specifically for boats. It is formulated to withstand the harsh marine environment, providing a durable and water-resistant coating that protects the wood from damage. Boat varnish is typically clear, allowing the natural beauty of the wood to shine through, and it enhances the wood’s grain and color.

The role of boat varnish in boat maintenance cannot be overstated. It serves as a protective shield, preventing the wood from absorbing water, which can lead to rot and decay. It also protects the wood from the damaging effects of UV rays, which can cause the wood to fade and crack over time. Furthermore, boat varnish enhances the boat’s aesthetic appeal, giving it a glossy, polished look.

It’s important to note that not all varnishes are suitable for boats. Boat varnish is specifically formulated to withstand the harsh marine environment, and using a regular varnish on a boat can result in premature failure and damage to the wood. Therefore, it’s crucial to use a varnish designed specifically for boats to ensure optimal protection and longevity.

Importance of Boat Varnish

Boat varnish serves a dual purpose: it protects the boat from environmental factors and enhances its aesthetic appeal. The marine environment is harsh, with constant exposure to water, salt, UV rays, and extreme temperatures. Without a protective coating, the wood on a boat can quickly deteriorate, leading to costly repairs or replacement. Boat varnish provides a durable, water-resistant barrier that protects the wood from these damaging factors.

In addition to its protective function, boat varnish also enhances the boat’s aesthetic appeal. A well-varnished boat is a sight to behold, with its glossy finish reflecting the sun’s rays and the water’s shimmer. The varnish enhances the natural beauty of the wood, highlighting its grain and color. Moreover, a well-maintained, varnished boat can significantly increase the boat’s resale value.

However, it’s important to note that the effectiveness of boat varnish depends on its proper application and maintenance. A poorly applied or maintained varnish can do more harm than good, leading to peeling, cracking, or blistering of the finish. Therefore, it’s crucial to follow the manufacturer’s instructions and best practices when applying and maintaining boat varnish.

Types of Boat Varnish

There are three main types of boat varnish: traditional varnish, synthetic varnish, and two-part varnish. Traditional varnish, also known as alkyd or oil-based varnish, is made from natural resins dissolved in oil and solvent. It provides a warm, amber finish and is known for its durability and ease of application. However, it requires more maintenance than other types of varnish and may not provide as much UV protection.

Synthetic varnish, also known as polyurethane varnish, is made from synthetic resins and provides a clear, hard finish. It offers excellent UV protection and is more durable than traditional varnish, but it can be more difficult to apply and may not provide the same depth of finish as traditional varnish.

Two-part varnish, also known as epoxy varnish, consists of a resin and a hardener that are mixed together before application. It provides the highest level of protection and durability, but it is the most difficult to apply and requires the most preparation. It’s also the most expensive type of boat varnish.

Each type of boat varnish has its pros and cons, and the best choice depends on various factors, including the type of wood on your boat, the climate and weather conditions, and the level of UV protection needed.

Factors to Consider When Buying Boat Varnish

When buying boat varnish, there are several factors to consider. The type of wood on your boat is one of the most important factors. Different types of wood have different characteristics and require different types of varnish. For example, hardwoods like teak and mahogany are dense and oily and require a varnish that can penetrate the wood’s surface. Softwoods like pine and cedar are less dense and require a varnish that can provide a hard, protective coating.

The climate and weather conditions are also important considerations. If your boat is exposed to harsh sunlight, a varnish with high UV protection is essential. If your boat is in a humid or rainy environment, a varnish with excellent water resistance is necessary. Additionally, temperature fluctuations can cause the wood to expand and contract, so a flexible varnish that can withstand these changes without cracking or peeling is important.

The level of UV protection needed is another key factor. UV rays can cause the wood to fade and crack over time, so a varnish with high UV protection is essential for boats exposed to strong sunlight. However, if your boat is stored indoors or in a shaded area, a varnish with lower UV protection may be sufficient.

Understanding Varnish Labels

Varnish labels contain important information about the product, including its type, application instructions, drying time, and safety precautions. However, they can also contain technical terms that may be confusing to the uninitiated. Here’s a brief explanation of some common terms on varnish labels:

“Alkyd” or “oil-based” refers to traditional varnishes made from natural resins dissolved in oil and solvent. “Polyurethane” refers to synthetic varnishes made from synthetic resins. “Epoxy” refers to two-part varnishes that consist of a resin and a hardener.

“UV protection” refers to the varnish’s ability to protect the wood from the damaging effects of UV rays. The higher the UV protection, the better the varnish will protect the wood from fading and cracking.

“Drying time” refers to the amount of time it takes for the varnish to dry to the touch. This is not the same as curing time, which is the amount of time it takes for the varnish to fully harden. It’s important to allow enough drying time between coats to ensure a smooth, even finish.

Understanding varnish labels is crucial to choosing the right product for your boat and applying it correctly. If you’re unsure about any terms or instructions on the label, don’t hesitate to contact the manufacturer or seek advice from a professional.

Top Boat Varnish Brands

There are many boat varnish brands on the market, each with its unique features and benefits. Here’s a brief overview of some top brands:

Interlux is a well-known brand in the marine industry, known for its high-quality products. Their varnishes offer excellent UV protection and durability, and they’re easy to apply.

Epifanes is another reputable brand, known for its traditional varnishes that provide a warm, amber finish. Their varnishes are durable and provide excellent UV and water resistance.

Pettit is known for its synthetic varnishes that provide a clear, hard finish. Their varnishes offer excellent UV protection and are more durable than traditional varnishes.

Each brand has its strengths and weaknesses, and the best choice depends on your specific needs and preferences. It’s always a good idea to read reviews and seek advice from professionals before making a decision.

How to Apply Boat Varnish

Applying boat varnish is a multi-step process that requires patience and attention to detail. The first step is to prepare the boat surface. This involves cleaning the surface to remove dirt, grease, and old varnish, sanding the surface to create a smooth, even base, and wiping the surface with a tack cloth to remove dust.

Once the surface is prepared, you can start applying the varnish. It’s important to stir the varnish thoroughly before application to ensure a consistent finish. Apply the varnish in thin, even coats using a high-quality brush. Avoid overloading the brush, as this can lead to drips and runs.

After applying a coat of varnish, allow it to dry thoroughly before applying the next coat. The drying time can vary depending on the type of varnish and the weather conditions, so it’s important to check the manufacturer’s instructions. Once the final coat is dry, lightly sand the surface to remove any imperfections and apply a final coat of varnish.

Maintenance of Varnished Surfaces

Maintaining varnished surfaces is crucial to preserving their appearance and longevity. Regular cleaning is one of the most important maintenance tasks. Use a mild soap and water to clean the surface, and avoid using harsh chemicals or abrasive cleaners that can damage the varnish.

Over time, the varnish may start to wear or fade, especially in areas exposed to strong sunlight or heavy traffic. In such cases, it may be necessary to reapply the varnish. Before reapplying, lightly sand the surface to remove any loose or flaking varnish, and clean the surface to remove dust and dirt.

It’s also important to inspect the varnished surfaces regularly for signs of damage, such as cracking, peeling, or blistering. If you notice any damage, it’s important to address it promptly to prevent further deterioration. This may involve sanding the damaged area and reapplying the varnish, or in severe cases, stripping the entire surface and re-varnishing it.

Common Mistakes to Avoid When Varnishing a Boat

When varnishing a boat, there are several common mistakes to avoid. One of the most common mistakes is incorrect preparation of the surface. This can include failing to clean the surface thoroughly, not sanding the surface evenly, or not removing dust after sanding. These mistakes can result in a rough, uneven finish, or cause the varnish to peel or flake.

Applying varnish in inappropriate weather conditions is another common mistake. Varnish should not be applied in extreme temperatures or high humidity, as this can cause the varnish to dry too quickly or not at all. It’s also important to avoid applying varnish in direct sunlight, as this can cause the varnish to dry unevenly.

Not allowing enough drying time between coats is another common mistake. If the previous coat is not fully dry, the next coat can cause it to wrinkle or bubble. It’s important to follow the manufacturer’s instructions for drying time, and to allow extra time in cold or humid conditions.

Safety Precautions When Using Boat Varnish

When using boat varnish, it’s important to take safety precautions to protect yourself and others. One of the most important precautions is to ensure proper ventilation. Varnish contains solvents that can produce harmful fumes, so it’s important to work in a well-ventilated area and to wear a respirator if necessary.

It’s also important to wear protective gear, including gloves and safety glasses, to protect your skin and eyes from the varnish. If you get varnish on your skin, wash it off immediately with soap and water. If you get varnish in your eyes, rinse them immediately with water and seek medical attention.

Finally, it’s important to store varnish safely. Keep it in a cool, dry place out of the reach of children and pets. Never store varnish near open flames or heat sources, as it is flammable.

Environmental Impact of Boat Varnish

Boat varnish can have a significant environmental impact, particularly on marine life. The solvents in varnish can leach into the water and harm aquatic organisms. Moreover, the process of producing and disposing of varnish can contribute to air and water pollution.

However, there are eco-friendly varnish options available that have a lower environmental impact. These varnishes are water-based and contain fewer volatile organic compounds (VOCs), which are harmful to the environment. They also tend to be less toxic to humans and animals.

While eco-friendly varnishes may not provide the same level of protection and durability as traditional varnishes, they are a good option for boat owners who want to minimize their environmental impact. It’s also important to apply and dispose of varnish responsibly to minimize its environmental impact.

Case Study: Successful Use of Boat Varnish

One successful example of the use of boat varnish is the restoration of a classic wooden yacht. The yacht, which had been neglected for years, was in poor condition, with faded, cracked wood and peeling varnish. The owner decided to restore the yacht to its former glory, and boat varnish played a crucial role in this process.

The first step was to strip the old varnish and sand the wood to create a smooth, even surface. Then, several coats of high-quality boat varnish were applied, with ample drying time between each coat. The result was a glossy, durable finish that enhanced the natural beauty of the wood and protected it from the harsh marine environment.

This case study demonstrates the transformative power of boat varnish. With the right product and application techniques, boat varnish can restore the beauty and longevity of a boat, making it a valuable investment for any boat owner.

Future Trends in Boat Varnish

As technology advances, we can expect to see new developments in boat varnish. One promising trend is the development of nano-technology-based varnishes. These varnishes contain tiny particles that can penetrate deep into the wood, providing superior protection and durability. They also offer better UV protection and are more resistant to scratches and abrasion.

Another emerging trend is the growing popularity of eco-friendly varnishes. As consumers become more aware of the environmental impact of their choices, there is increasing demand for products that are less harmful to the environment. This has led to the development of water-based varnishes and varnishes with lower VOC content.

Finally, we can expect to see more brands and products entering the market, offering consumers more choices and competition. This is good news for boat owners, as it means more options and potentially lower prices.

Conclusion

In conclusion, boat varnish is a crucial aspect of boat maintenance, providing protection against environmental factors and enhancing the boat’s aesthetic appeal. Understanding the different types of boat varnish and how to choose, apply, and maintain them can help boat owners protect their investment and keep their boat looking its best for years to come.

While there are many factors to consider when choosing a boat varnish, the most important thing is to choose a product that is specifically designed for boats and suits your specific needs and conditions. It’s also crucial to apply and maintain the varnish correctly to ensure its effectiveness and longevity.

As technology advances and consumer preferences evolve, we can expect to see new developments in boat varnish, offering boat owners more options and better products. However, the basic principles of boat varnishing – protection, enhancement, and maintenance – will remain the same.

FAQs

What is boat varnish?

Boat varnish, also known as marine varnish, is a protective finish designed specifically for boats. It protects the wood from environmental factors and enhances its aesthetic appeal.

Why is boat varnish important?

Boat varnish protects the wood on a boat from harsh environmental conditions, including UV rays, saltwater, and extreme temperatures. It also enhances the boat’s aesthetic appeal, giving it a glossy, polished look.

How do I choose the right boat varnish?

When choosing a boat varnish, consider factors such as the type of wood on your boat, the climate and weather conditions, and the level of UV protection needed. Also, make sure to choose a varnish that is specifically designed for boats.

How do I apply boat varnish?

Applying boat varnish involves preparing the boat surface, applying the varnish in thin, even coats, and allowing enough drying time between coats. It’s important to follow the manufacturer’s instructions and best practices to ensure a smooth, durable finish.

How do I maintain varnished surfaces?

Maintaining varnished surfaces involves regular cleaning with a mild soap and water, reapplying the varnish as needed, and inspecting the surfaces regularly for signs of damage.