Hey there, DIY enthusiasts and professionals alike! Ever wondered how to make accurate measurements without the hassle of traditional tape measures? Enter the laser measure, a nifty tool that uses laser technology to provide precise readings of distance, area, and volume. It’s like having a virtual tape measure at your fingertips, making your projects a breeze.

Using a laser measure accurately is crucial for getting precise results in your projects, whether you’re hanging a picture frame or renovating a room. However, there are common mistakes that many users fall into, leading to inaccurate measurements and potential project mishaps. Let’s dive into these pitfalls and learn how to avoid them for seamless measuring experiences.

Our Top Laser Measure Picks

BOSCH GLM165-40 Blaze 165 Ft Laser Distance Measure

Check on AmazonKey Specs

- Accuracy: Measures up to 165 feet with an accuracy of +/- 1/16 inch, ensuring reliable and precise results for any project. Easy-to-Use: Simply press a button to begin measuring. The compact design fits comfortably in your pocket, and the backlit color display makes it easy to read measurements, even in dimly lit areas. Live Measuring: Like a tape measure, it provides real-time adjustments as you move closer or farther from the target, offering continuous measurement feedback. Auto Square: The GLM165-40 includes an auto square feature, allowing the tool to automatically calculate square footage with just a press of a button.

- Durability: Built for tough environments, the laser measure is IP54 rated, making it resistant to dust and water, ideal for use on construction sites.

- Multiple Measurement Functions: Besides measuring distance, it can calculate square footage, volume, and indirect measurements, making it versatile for various tasks.

- Add/Subtract Function: The device allows users to add or subtract measurements for more complex calculations.

- Laser Specifications: The laser used is a Class II, 635 nm with less than 1 mW power, providing safe and effective measurements.

The BOSCH GLM165-40 Blaze 165 Ft Laser Distance Measure is an excellent tool for precise and efficient distance measurement, perfect for both professionals and DIY enthusiasts.

Laser Measure 50M/165ft,RockSeed Digital Laser Distance Meter

Check on AmazonKey Specs:

- High Accuracy & Unit Switchable: The RockSeed laser measure features unique 2 Bubble Levels for more precise measurements compared to traditional single-bubble models. With laser precision technology, it offers an accuracy of ±1/16 inch and a measurement range of up to 165 feet. You can switch between Meters (M), Inches (In), and Feet (Ft) for versatile use.

- LCD Backlight & Mute Setting: The large backlit LCD screen ensures easy visibility in dark environments, and the mute setting lets you silence the beep, which is ideal for quiet places like libraries, classrooms, or offices.

- Multiple Measurement Features: This device supports a range of measurements, including

- distance, area, volume, and continuous measurement. It also supports the

- Pythagorean method for three-point measurements, addition and subtraction functions, and

- 20 groups of data memory. An auto shut-down feature activates after 150 seconds of inactivity to save battery life.

- Durable and Handy Design: The laser measure is IP54-rated, offering waterproof and dustproof protection, making it ideal for tough work environments. Its portable size and rubberized body ensure a good grip and added durability. It also includes a wrist strap for easier handling and carrying.

The RockSeed Digital Laser Distance Meter 50M/165ft is an advanced tool designed for precise measurements in various settings, offering a combination of accuracy, convenience, and durability.

BOSCH GLM165-25G 165 Ft Blaze Green-Beam Laser Distance Measure

Check on AmazonKey Specs:

- Accuracy: Measures up to 165 feet with an impressive accuracy of +/- 1/16 inch, making it highly precise for both professional and home use.

- Green-Beam Technology: Unlike standard red laser beams, the green beam is up to 4 times brighter, offering superior visibility, especially in bright or challenging lighting conditions.

- Backlit Color Display: The device features a backlit color display, making it easy to read measurements even in low-light or dark environments. The display shows numbers with clear resolution for accurate readings.

- Durability: Built to withstand tough jobsite conditions, this laser distance measure is IP65-rated, offering water and dust resistance for long-lasting performance.

- Live Measuring: The laser provides real-time measurement, adjusting automatically as you move closer or farther from the target, similar to a traditional tape measure.

- Add/Subtract Functionality: It allows users to add or subtract measurements, making it easy to calculate and adjust distances with ease.

- Class II Laser: This device uses a Class II laser with a power output of <1 mW, making it safe for typical use.

The BOSCH GLM165-25G is perfect for those who need a reliable, easy-to-use, and highly accurate laser distance measure that performs well in various environments. Its green beam, backlit display, and durability make it ideal for both indoor and outdoor use.

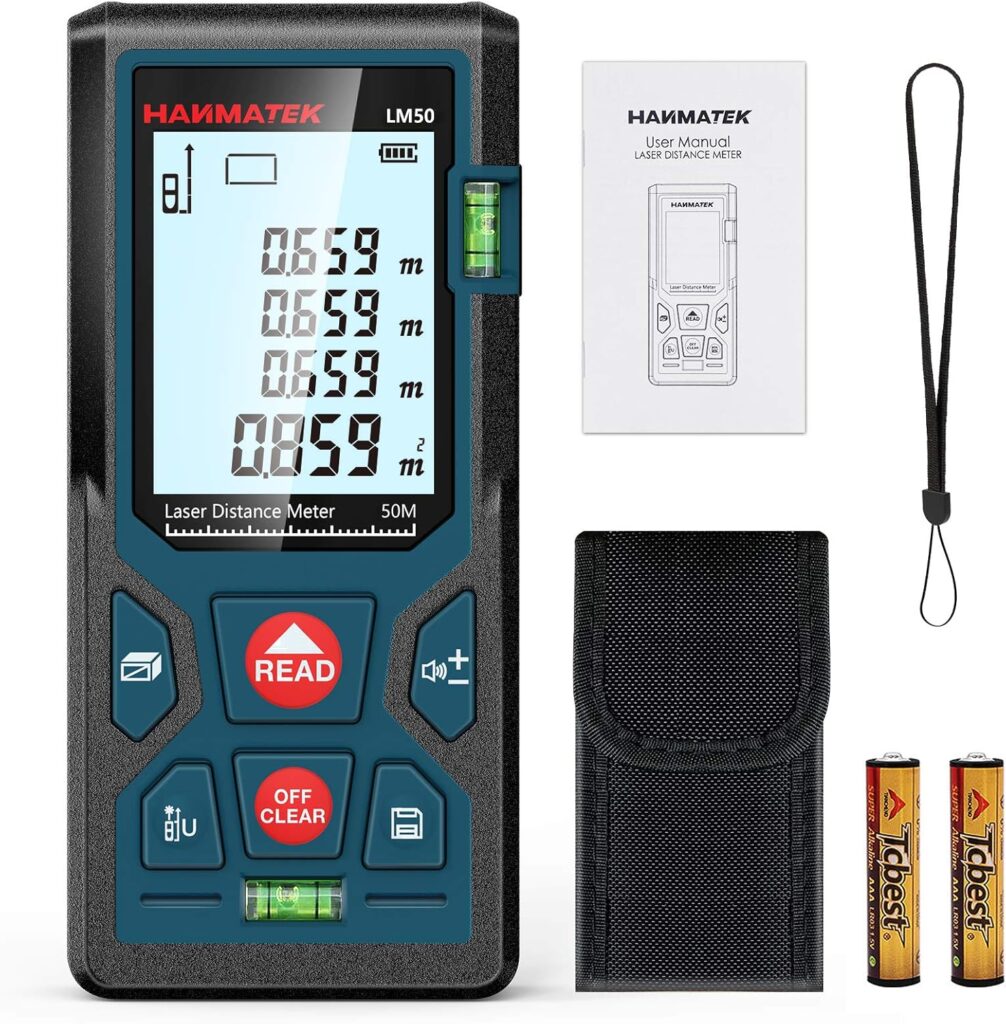

165ft/50m Laser Measure Ft/in/M Switching LM50 Laser Measurement Tool

Check on AmazonKey Specs:

- Measurement Range: This laser measure can measure distances up to 165 feet (50 meters), making it suitable for a variety of tasks, from small projects to larger-scale measurements.

- Unit Switching: The device allows for easy switching between feet, inches, and meters (Ft/in/M), offering flexibility to suit different measurement needs and preferences.

- Material: Made from Acrylonitrile Butadiene Styrene (ABS), known for its durability and resistance to impact, ensuring the tool can withstand daily use.

- Compact Design: Weighing only 100 grams, it is lightweight and portable, making it easy to carry and use on the go.

- Batteries Included: The laser measure comes with batteries included, ensuring it’s ready for use right out of the box.

The 165ft/50m Laser Measure Ft/in/M Switching LM50 Laser Measurement Tool by HANMATEK is a compact and efficient tool designed for accurate distance measurements.

Laser Measure 50M/165ft,RockSeed Digital Laser Distance Meter

Check on AmazonKey Specs:

- High Accuracy & Unit Switchable: With a precision of ±1/16 inch, it can measure up to 165 feet (50 meters). The tool allows easy switching between meters, inches, and feet, ensuring flexibility for different users.

- LCD Backlight & Mute Setting: The large backlight screen ensures clear visibility even in low-light conditions. The mute setting allows you to turn off the measuring beep, making it ideal for use in quiet places like libraries or classrooms.

- Multiple Measurement Functions: This device supports a variety of measurements, including area, distance, length, volume, and continuous measurement. It also includes the Pythagorean method (three points) for indirect measurement. Additional features like addition/subtraction, 20 data memory groups, and manual data deletion are available.

- Durable and Handy Design: The IP54 waterproof and dustproof design ensures the laser meter can withstand tough conditions. The hard rubber body offers a solid grip, and the included wrist strap makes it easy to carry.

- Power Saving & Long Battery Life: The device will automatically shut down after 150 seconds without operation, saving battery life. It comes with 1.5V AAA batteries, ready for use right out of the box.

The RockSeed Digital Laser Distance Meter offers advanced features and high accuracy for various measuring tasks.

Overview of the Common Mistakes to Avoid

| Mistake | Consequence |

|---|---|

| Not calibrating the laser measure | Inaccurate measurements |

| Ignoring the user manual | Potential errors in operation |

| Using the wrong settings | Incorrect readings |

Not Calibrating the Laser Measure

Calibrating your laser measure is like tuning a musical instrument before a performance. It ensures that the device is providing accurate measurements by aligning its internal components correctly. Most laser measures come with a calibration process outlined in the user manual, typically involving setting a reference point for precise readings.

Skipping the calibration step might seem like a time-saver, but it can lead to significant measurement errors. Imagine thinking your wall is 10 feet away when it’s actually 9 feet and having to redo your entire project. Taking a few minutes to calibrate your laser measure can save you from such headaches.

Consequences of Not Calibrating the Device

- Incorrect measurements leading to project errors

- Loss of time and materials due to rework

- Diminished trust in the accuracy of the tool

Ignoring the User Manual

Who needs a manual, right? Wrong! The user manual is your best friend when it comes to understanding how to operate your laser measure effectively. It provides specific instructions on everything from initial setup to advanced features, ensuring you get the most out of your device.

By ignoring the user manual, you risk missing out on essential tips and tricks for using your laser measure correctly. From battery replacement guidelines to troubleshooting common issues, the manual is a treasure trove of information that can prevent user errors and enhance your measuring experience.

How Ignoring the Manual Can Lead to Mistakes

- Incorrect usage of advanced features

- Misinterpretation of error codes

- Lack of knowledge on maintenance best practices

Using the Wrong Settings

Did you know that laser measures come with different settings for various measurement tasks? From switching between metric and imperial units to adjusting for indirect measurements, selecting the right settings is crucial for obtaining accurate results. Using the wrong settings can throw off your measurements and lead to project inaccuracies.

Before starting a new project, take a moment to review the settings on your laser measure and ensure they align with your measurement needs. It’s a small step that can make a big difference in the precision of your results.

Consequences of Using the Wrong Settings

- Inaccurate distance calculations

- Mismatched units causing confusion

- Difficulty in converting measurements for project consistency

FAQ Section

Frequently Asked Questions

How often should I calibrate my laser measure?

It’s recommended to calibrate your laser measure before each critical measurement task to ensure accuracy. Regular calibration helps maintain the device’s precision over time.

Can environmental factors affect laser measure readings?

Absolutely! Factors like bright sunlight, reflective surfaces, and obstacles in the measurement path can impact the accuracy of your readings. Be mindful of your surroundings for reliable results.

Why is it essential to double-check measurements?

Double-checking measurements acts as a safety net against errors. It allows you to catch any discrepancies before proceeding with your project, saving you time and resources in the long run.