In the world of precision engineering and manufacturing, accurate measurements are crucial. Calipers, with their ability to measure dimensions with high precision, play a vital role in ensuring the quality and consistency of products. Whether you are a machinist, a carpenter, or a scientist, using calipers correctly can make a significant difference in the outcome of your work. This article will delve into the essential tips for achieving precise measurements with calipers, covering everything from calibration to proper technique and maintenance.

Our Top Accurate Measurements with Calipers Picks

Sylvac 30-810-1536 S_CAL EVO Bluetooth Vernier Caliper

Check on Amazon

Key Specs

- Measuring Range: 300 millimeters

- Max Error: 20 μm (micrometers)

- Water Resistant: Rated IP67, making it resistant to water and suitable for environments with coolants and lubricants

- Bluetooth Connectivity: Built-in Bluetooth 4.0 transmitter, with a transmission range up to 15 meters

- Absolute System: Provides consistent, repeatable readings without the need for zeroing

The Sylvac 30-810-1536 S_CAL EVO Bluetooth Vernier Caliper is a high-precision measuring tool designed for professionals in need of accurate and reliable measurements, especially in environments involving coolants and lubricants. With its advanced Bluetooth connectivity and robust construction, this caliper is ideal for heavy-duty industrial and technical applications.

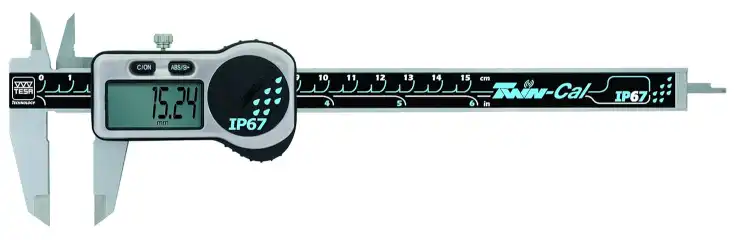

TESA TES00530319 Twin-Cal IP67 Digital Caliper

Check on Amazon

Key Specs:

- Measuring Range: 0 mm – 150 mm (0″ – 6″)

- Resolution: 0.01 mm (0.0005 inches)

- Display Type: Digital, for easy and precise readings

- Data Output: Yes, allows for data transfer to other devices for further analysis

- Material: Made from durable PLA (Polylactic Acid) and PE (Polyethylene) for increased strength and longevity

- Manufacturer: TESA (known for high-quality precision tools)

- Protection Class: IP67, ensuring protection from dust and immersion in water

The TESA TES00530319 Twin-Cal IP67 Digital Caliper is a highly accurate and durable digital measuring tool designed for precise measurements in demanding environments. With its IP67 rating, it’s suitable for use in conditions involving dust and moisture, making it ideal for industrial and workshop settings.

FEGIANCHE IP67 Digital Caliper

Check on AmazonKey Specs:

- Suitable Size: Compact and easy to store and carry, making it convenient for on-the-go use.

- Ease of Use: User-friendly design for straightforward operation, ensuring quick and efficient measurements.

- Stability: Reliable and stable performance over extended periods, allowing for consistent results.

- Durability: Built to last with long service life, ensuring the caliper remains functional through frequent use.

- Wide Range of Applications: Perfect for various measurement situations, including workshops, construction, and engineering tasks.

The FEGIANCHE IP67 Digital Caliper is a versatile and durable tool designed for accurate measurements across various applications. Its features make it an ideal choice for professionals and DIY enthusiasts alike.

Overview of Tips for Precise Measurements with Calipers

To achieve accurate measurements with calipers, several key tips need to be followed diligently. Understanding the different types of calipers available and selecting the right one for the task at hand is the first step. Proper calibration, correct measurement techniques, zero-point adjustment, avoiding parallax errors, and regular maintenance are all crucial aspects to consider. By implementing these tips effectively, you can ensure that your measurements are precise and reliable, leading to improved product quality and operational efficiency.

Types of Calipers and Choosing the Right One

Calipers come in various types, including Vernier, Dial, and Digital calipers. Each type has its advantages and is suited for specific measurement tasks. Vernier calipers are traditional and offer high accuracy, Dial calipers provide easy readability, and Digital calipers offer quick and precise measurements. Choosing the right type of calipers for your application is essential to ensure accurate results. For example, if you need to measure very small dimensions, a Digital caliper with a high resolution would be more suitable than a Vernier caliper.

| Caliper Type | Advantages | Suitable Applications |

|---|---|---|

| Vernier Calipers | High accuracy | Precision engineering |

| Dial Calipers | Easy readability | Machine setup |

| Digital Calipers | Quick and precise measurements | Quality control |

Proper Calibration of Calipers

Calibrating your calipers regularly is essential to maintain their accuracy. Over time, calipers can drift out of calibration due to wear and tear or environmental factors. By calibrating your calipers using known reference standards, you can ensure that your measurements are reliable. To calibrate calipers accurately, follow these steps:

1. Clean the measuring surfaces of the calipers.

2. Use a calibrated reference standard of known dimensions.

3. Compare the measurements taken with the calipers to the known dimensions.

4. Make any necessary adjustments to bring the calipers back into calibration.

By following these calibration steps, you can trust that your calipers are providing accurate measurements, leading to better quality control and product consistency.

FAQ

How often should I calibrate my calipers?

A: It is recommended to calibrate your calipers at least once a month or more frequently if you notice any discrepancies in your measurements.

Can I use the same calipers for different types of measurements?

A: While calipers are versatile tools, it is best to use specific calipers for different types of measurements to ensure accuracy and precision.