Precision matters, and that’s where laser levels redefine accuracy. Whether aligning tiles, installing shelves, or tackling large-scale construction projects, these tools project straight, reliable reference lines that eliminate guesswork. Unlike traditional bubble levels, laser levels provide enhanced visibility, extended range, and pinpoint precision, making them indispensable for professionals and DIY enthusiasts alike.

From compact cross-line models to advanced rotary designs, there’s a laser level suited for every task. Self-leveling technology, multiple beam orientations, and high-visibility diodes ensure flawless alignment even in challenging environments. Whether you’re a contractor striving for perfection or a homeowner handling renovations, a laser level simplifies the job with unmatched efficiency.

Investing in the right laser level means faster setups, improved accuracy, and professional results every time. Find the ideal model to elevate your craftsmanship and bring precision to every project.

Our Top Laser Levels Picks

Johnson Level Laser Kit

Check on Amazon

Key Specs

- Laser Lines: Horizontal and vertical

- Battery Life: 12 hours with 3 AAA batteries

- Self-Leveling Range: +/- 6 degrees

- Accuracy: +/- 1/4″ at 35′

- Range: Up to 100 ft. (depending on light conditions)

The Johnson Level Laser Kit is an essential tool for anyone needing precise leveling for home improvement projects. This self-leveling cross-line laser projects two clear, distinct lines—one horizontal and one vertical—to assist with various tasks such as hanging pictures, tiling walls, and leveling cabinets. Its 360° graded base simplifies angle adjustments, ensuring superior accuracy. With a battery life of 12 hours and a self-leveling range of +/- 6 degrees, this laser level is perfect for both professionals and DIY enthusiasts.

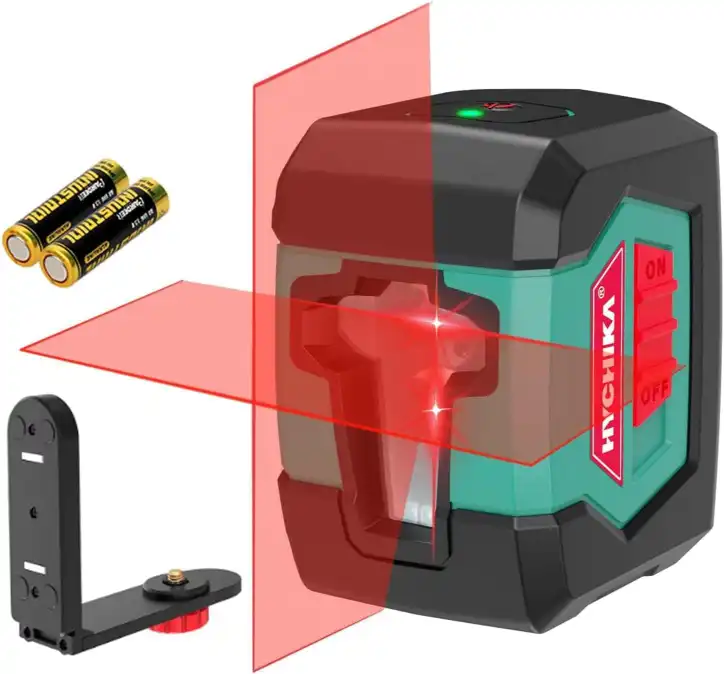

HYCHIKA 50 Feet Cross Line Laser

Check on AmazonKey Specs:

- Laser Patterns: Cross-line, horizontal, vertical

- Self-Leveling Range: ≤4°

- Laser Visibility: Up to 50 feet

- Battery Life: 20 hours with 2 AA batteries

- Protection Grade: IP54 (waterproof, dust-proof, shock-resistant)

The HYCHIKA 50 Feet Cross Line Laser is an ideal tool for DIY enthusiasts and professionals alike. Featuring dual laser modules, it allows easy switching between cross-line, horizontal, and vertical patterns. Its self-leveling function ensures precise alignment, automatically leveling within 6 seconds when tilted at ≤4°. The compact and shock-resistant design, combined with a 20-hour battery life, makes it highly versatile for indoor projects. It also includes a magnetic support for easy attachment to metal surfaces.

Huepar Self-Leveling Green Laser Level

Check on Amazon

Key Specs:

- Laser Type: Green 360° horizontal and 140° vertical beam

- Battery: 7.4V/1500mAh Li-ion, up to 10 hours

- Range: 197 feet with outdoor pulse mode

- Accuracy: ±1/9″ at 33 feet

- Mounting: Magnetic base, tripod mount, and multiple installation options

The Huepar Self-Leveling Green Laser Level is a versatile and reliable tool for both professional and DIY projects. With a 360° horizontal line and two green plumb dots, it offers comprehensive coverage for a variety of leveling and alignment tasks. The Li-ion battery provides up to 10 hours of runtime, and the Type-C charging port ensures easy recharging. Its outdoor pulse mode extends the range up to 197 feet, even in bright conditions, and the durable, IP54-rated design ensures longevity.

BOSCH GLL25-10 30 Ft Self-Leveling Cross-Line Laser

Check on Amazon

Key Specs:

- Range: Up to 30 feet

- Accuracy: ±5/16″ at 30 feet

- Laser Type: Class II, 635 nm; <1 mW

- Mounting: Includes a flexible 360° rotating mounting device

- Size: 2.6″L x 1.1″W

The BOSCH GLL25-10 Self-Leveling Cross-Line Laser offers precise leveling and alignment with a visible range of up to 30 feet. Its cross-line mode projects two bright, accurate lines for a variety of applications. This compact and lightweight tool is easy to store and use, making it ideal for DIY and professional projects. The included mounting device allows flexible positioning and fine-tuning, ensuring convenience and versatility.

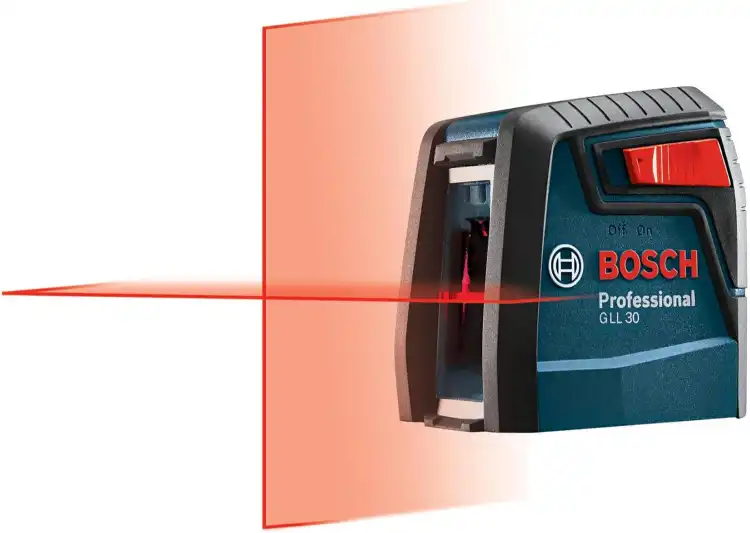

BOSCH GLL 30 FT Self-Leveling Cross-Line Laser

Check on Amazon

Key Specs:

- Range: Up to 30 feet

- Accuracy: ±5/16″ at 30 feet

- Laser Type: Class II, 635 nm; <1 mW

- Mounting: Includes a flexible 360° rotating mounting device

- Size: 2.8″L x 2.2″W

The BOSCH GLL 30 FT Self-Leveling Cross-Line Laser is a versatile tool designed for precision in leveling and alignment. It projects two bright, accurate lines up to 30 feet, making it ideal for a variety of applications. Its compact, lightweight design ensures easy storage and portability. The flexible mounting device allows for quick setup and fine-tuning, while the laser’s accuracy of ±5/16″ at 30 feet guarantees reliable results.

Understanding the Importance of Laser Levels in Construction

Laser levels are crucial in construction for several reasons. First, they provide a high level of accuracy that is unmatched by traditional leveling methods. This accuracy is vital in construction, where even the slightest deviation can lead to significant problems down the line. With laser levels, builders can ensure that their work is perfectly level and aligned, reducing the risk of costly mistakes and rework.

Second, laser levels increase efficiency on the construction site. They allow for quick and easy leveling and alignment, saving builders valuable time. This efficiency can lead to cost savings, as projects can be completed faster and with fewer resources. Furthermore, laser levels are easy to use, requiring minimal training. This ease of use makes them accessible to all workers, regardless of their level of experience or expertise.

Finally, laser levels enhance safety on the construction site. They eliminate the need for workers to climb ladders or scaffolding to make measurements, reducing the risk of falls and other accidents. By using a laser level, workers can make accurate measurements from a safe distance. This safety aspect is particularly important in the construction industry, where workplace accidents are unfortunately common.

Different Types of Laser Levels Used in Construction

There are several types of laser levels used in construction, each with its own unique features and applications. The most common types include dot lasers, line lasers, and rotary lasers. Dot lasers project a single dot onto a surface, making them ideal for tasks such as aligning objects vertically or horizontally. Line lasers, on the other hand, project a straight line onto a surface, making them perfect for leveling tasks.

Rotary lasers are more advanced and versatile. They project a 360-degree laser line around a room, making them ideal for larger construction projects. These lasers are often used for tasks such as installing ceiling tiles, aligning walls, and leveling floors. Some rotary lasers also come with additional features such as dual beams for simultaneous horizontal and vertical leveling, and grade match and planeLok capabilities for advanced leveling and alignment tasks.

Choosing the right laser level for your construction project depends on the specific tasks at hand. It’s important to consider the size of the project, the level of precision required, and the working conditions. For instance, a dot laser may be sufficient for a small home renovation project, while a rotary laser may be necessary for a large commercial construction project.

Key Features to Look for When Buying a Laser Level for Construction

When buying a laser level for construction, there are several key features to consider. First and foremost, accuracy is paramount. The laser level should provide a high level of accuracy, typically within 1/8 of an inch at 30 feet. Anything less than this may not provide the precision required for construction tasks.

Second, consider the range of the laser level. This refers to the maximum distance that the laser beam can reach while still maintaining accuracy. For large construction projects, a laser level with a long range is essential. Other important features include self-leveling capabilities, which ensure the laser level is always perfectly level, and durability, as the device will likely be used in harsh construction environments.

Finally, consider the type of laser level that is best suited to your needs. As mentioned earlier, there are several types of laser levels, including dot lasers, line lasers, and rotary lasers. Each type has its own unique features and applications, so it’s important to choose the one that best fits your construction project.

Understanding the Accuracy of Laser Levels in Construction

The accuracy of laser levels in construction is critical. Even the slightest deviation can lead to significant problems, such as misaligned walls or uneven floors. Therefore, it’s important to understand how to measure the accuracy of a laser level. This is typically done by measuring the deviation from the horizontal or vertical line over a certain distance. The smaller the deviation, the more accurate the laser level.

Most laser levels used in construction have an accuracy of within 1/8 of an inch at 30 feet. However, some high-end models can provide even greater accuracy. It’s also worth noting that the accuracy of a laser level can be affected by several factors, including the quality of the device, the working conditions, and the user’s skill level. Therefore, it’s important to regularly check the accuracy of your laser level and recalibrate it if necessary.

Despite their high level of accuracy, laser levels should not be used as the sole tool for leveling and alignment tasks in construction. They should be used in conjunction with other tools and methods to ensure the highest level of accuracy. For instance, a laser level can be used to provide a visual guide, while a spirit level can be used to confirm the accuracy of the work.

The Role of Laser Levels in Ensuring Precision in Construction

Laser levels play a crucial role in ensuring precision in construction. They provide a visual guide that builders can follow to ensure their work is perfectly level and aligned. This precision is vital in construction, where even the slightest deviation can lead to significant problems down the line.

For instance, when installing a window, a laser level can be used to ensure the window is perfectly level and aligned with the rest of the building. If the window is not level, it may not open and close properly, and it may not provide a tight seal against the elements. Similarly, when installing a door, a laser level can be used to ensure the door is perfectly aligned with the frame. If the door is not aligned, it may not close properly, leading to security and insulation issues.

Aside from ensuring precision, laser levels also increase efficiency on the construction site. They allow for quick and easy leveling and alignment, saving builders valuable time. This efficiency can lead to cost savings, as projects can be completed faster and with fewer resources. Furthermore, laser levels are easy to use, requiring minimal training. This ease of use makes them accessible to all workers, regardless of their level of experience or expertise.

How to Use a Laser Level in Construction: A Step-by-Step Guide

Using a laser level in construction is relatively straightforward. The first step is to set up the laser level on a stable surface or a tripod. The device should be placed at a height that allows the laser beam to reach all the necessary points. Once the laser level is set up, it can be turned on and the beam can be projected onto the desired surface.

The next step is to adjust the laser level until it is perfectly level. Most laser levels have self-leveling capabilities, which make this process easy. However, some models require manual leveling. This can be done by adjusting the device until the bubble in the built-in vial is centered. Once the laser level is perfectly level, it can be used to guide the construction work.

For instance, if you’re installing a window, you can use the laser level to project a beam onto the wall. This beam will serve as a visual guide, helping you ensure the window is perfectly level and aligned. Similarly, if you’re installing a door, you can use the laser level to project a beam onto the frame. This beam will help you ensure the door is perfectly aligned with the frame.

Safety Measures to Consider When Using Laser Levels in Construction

While laser levels are a valuable tool in construction, they also pose certain safety risks. The most significant risk is eye injury from direct exposure to the laser beam. Therefore, it’s important to never look directly into the laser beam, and to always wear protective eyewear when using a laser level.

Another safety measure to consider is the stability of the laser level. The device should always be set up on a stable surface or a tripod to prevent it from falling over. If the laser level falls over, it could cause injury or damage to the device. Furthermore, the laser level should always be securely fastened to the surface or tripod to prevent it from moving during use.

Finally, it’s important to be aware of others when using a laser level. The laser beam can be harmful to others if it hits them in the eye. Therefore, always make sure the area is clear before turning on the laser level, and always turn off the device when it’s not in use. By following these safety measures, you can use a laser level safely and effectively in construction.

The Impact of Weather Conditions on the Performance of Laser Levels

Weather conditions can have a significant impact on the performance of laser levels. Extreme temperatures, for instance, can affect the accuracy of the device. Cold temperatures can cause the laser beam to contract, while hot temperatures can cause it to expand. This can lead to inaccurate measurements, so it’s important to use the laser level in a controlled environment whenever possible.

Humidity can also affect the performance of laser levels. High humidity can cause condensation to form on the device, which can interfere with the laser beam. This can lead to inaccurate measurements, so it’s important to keep the laser level dry and to use it in a low-humidity environment whenever possible.

Finally, wind can affect the stability of the laser level. If the device is set up on a tripod, strong winds can cause it to move or fall over. This can lead to inaccurate measurements and potential damage to the device. Therefore, it’s important to secure the laser level properly and to use it in a sheltered location whenever possible.

The Role of Laser Levels in Large Scale Construction Projects

Laser levels play a crucial role in large scale construction projects. They are used to establish accurate level points and lines, which guide the construction work. This is particularly important in large scale projects, where even the slightest deviation can have significant consequences.

For instance, in the construction of a skyscraper, a laser level can be used to ensure the floors are perfectly level and the walls are perfectly aligned. If the floors are not level, it could lead to structural instability. Similarly, if the walls are not aligned, it could lead to aesthetic and functional issues. Therefore, the use of a laser level in such projects is crucial.

Aside from ensuring accuracy, laser levels also increase efficiency in large scale construction projects. They allow for quick and easy leveling and alignment, saving valuable time. This efficiency can lead to cost savings, as projects can be completed faster and with fewer resources. Furthermore, laser levels are easy to use, requiring minimal training. This ease of use makes them accessible to all workers, regardless of their level of experience or expertise.

Maintenance and Care Tips for Laser Levels in Construction

Proper maintenance and care are crucial to the performance and longevity of laser levels. One of the most important maintenance tasks is cleaning the device. Dust and debris can interfere with the laser beam, leading to inaccurate measurements. Therefore, it’s important to clean the laser level regularly with a soft cloth.

Another important maintenance task is checking the accuracy of the laser level. Over time, the device may lose its accuracy due to wear and tear. Therefore, it’s important to check the accuracy regularly and to recalibrate the device if necessary. Most laser levels come with instructions on how to do this.

Finally, it’s important to handle the laser level with care. The device should be stored in a protective case when not in use to prevent damage. Furthermore, the device should be handled gently to prevent drops and other impacts, which can damage the internal components and affect the accuracy of the device.

Understanding the Limitations and Challenges of Using Laser Levels in Construction

While laser levels are a valuable tool in construction, they also have certain limitations and challenges. One of the main limitations is their dependence on light. The laser beam can be difficult to see in bright sunlight, making the device less effective in outdoor construction projects. There are, however, laser levels available that come with a pulse mode feature that can be used with a laser detector for outdoor use.

Another limitation is the range of the laser level. While some models can reach up to several hundred feet, others have a much shorter range. This can be a challenge in large construction projects, where the laser beam may not reach all the necessary points. In such cases, additional tools or methods may be needed to ensure accuracy.

Finally, laser levels require a stable surface or a tripod for setup. This can be a challenge in uneven or unstable construction sites. In such cases, a laser level with a self-leveling feature can be beneficial. This feature allows the device to automatically adjust to the level, regardless of the surface it’s placed on.

The Future of Laser Levels in the Construction Industry

The future of laser levels in the construction industry looks promising. With advancements in technology, these devices are becoming more accurate, efficient, and versatile. For instance, some laser levels now come with features such as dual beams for simultaneous horizontal and vertical leveling, and grade match and planeLok capabilities for advanced leveling and alignment tasks.

Furthermore, the integration of laser levels with other technologies is expected to enhance their capabilities. For instance, the integration of laser levels with digital measuring tools can provide real-time measurements, making construction tasks even more efficient. Similarly, the integration of laser levels with 3D modeling software can provide a visual representation of the construction project, helping builders plan and execute their work more effectively.

Despite these advancements, the basic principle of laser levels remains the same: to provide a visual guide for leveling and alignment tasks in construction. Therefore, while the technology may evolve, the role of laser levels in the construction industry is likely to remain unchanged.

Training and Skills Required to Operate Laser Levels in Construction

Operating a laser level in construction requires certain training and skills. While these devices are relatively easy to use, proper training is necessary to ensure accuracy and safety. Most manufacturers provide instructions on how to use their laser levels, and some even offer training courses. These courses typically cover topics such as setting up the device, adjusting the level, and interpreting the results.

In addition to training, certain skills are beneficial when operating a laser level. These include attention to detail, as the accuracy of the device depends on precise setup and adjustment; problem-solving skills, as issues may arise during use; and basic math skills, as measurements and calculations are often involved in leveling and alignment tasks.

Finally, safety skills are crucial when operating a laser level. As mentioned earlier, these devices pose certain safety risks, such as eye injury from direct exposure to the laser beam. Therefore, it’s important to know how to use the device safely, including wearing protective eyewear and ensuring the area is clear before turning on the laser level.

Conclusion: The Indispensable Role of Laser Levels in Modern Construction

In conclusion, laser levels play an indispensable role in modern construction. They provide a high level of accuracy that is unmatched by traditional leveling methods, making tasks quicker, easier, and more precise. Furthermore, they enhance safety on the construction site, reducing the need for workers to make risky measurements at heights or in difficult positions.

Despite their limitations and challenges, the benefits of laser levels far outweigh their drawbacks. With advancements in technology, these devices are becoming more accurate, efficient, and versatile, making them an invaluable tool in the construction industry. Whether you’re a professional builder or a DIY enthusiast, a laser level can make your construction tasks easier and more efficient.

As the construction industry continues to evolve, the role of laser levels is likely to become even more important. With the integration of laser levels with other technologies, these devices can provide real-time measurements and visual representations of construction projects, enhancing their capabilities and making construction tasks even more efficient. Therefore, the future of laser levels in the construction industry looks promising.

Frequently Asked Questions about Laser Levels in Construction

What is a laser level?

A laser level is a tool used in construction to establish accurate level points and lines. It projects a beam of light that is used as a visual guide for leveling and alignment tasks.

Why are laser levels important in construction?

Laser levels are important in construction because they provide a high level of accuracy that is unmatched by traditional leveling methods. This accuracy is vital in construction, where even the slightest deviation can lead to significant problems. Furthermore, laser levels enhance safety on the construction site by reducing the need for risky measurements.

What are the different types of laser levels?

There are several types of laser levels, including dot lasers, line lasers, and rotary lasers. Dot lasers project a single dot onto a surface, line lasers project a straight line, and rotary lasers project a 360-degree line. Each type has its own unique features and applications.

What are the key features to look for when buying a laser level?

When buying a laser level, key features to look for include accuracy, range, self-leveling capabilities, and durability. It’s also important to consider the type of laser level that is best suited to your needs.

How do you use a laser level in construction?

To use a laser level in construction, first set up the device on a stable surface or a tripod. Turn on the device and adjust it until it is perfectly level. The laser beam can then be projected onto the desired surface to guide the construction work.